Hose sealed floor drain

A technology of sealed floor drains and hoses, which is applied in indoor sanitary pipeline installations, water supply installations, buildings, etc., can solve the problems of manual cleaning, poor self-cleaning ability, and pipeline loss of barriers, etc., and achieves convenient use and maintenance, and self-cleaning Strong ability and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

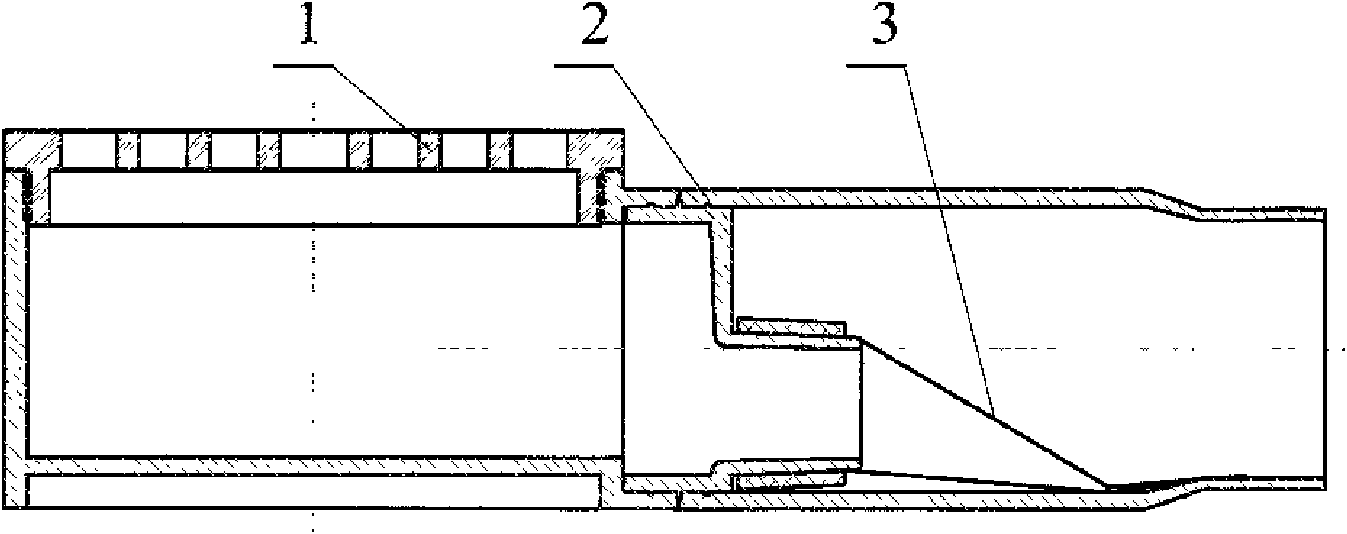

[0010] refer to figure 1 The hose-sealed floor drain is composed of a floor drain cover 1, a floor drain body 2 and a plastic hose 3. The floor drain cover 1 is installed on the floor drain body 2. One end of the plastic hose 3 is fixed on the floor drain body 2, and the other end is a free end. Closed by its own gravity. The working process of the hose-sealed floor drain is as follows: the water flows into the floor drain body 2 through the floor drain cover 1 and gathers in the plastic hose 3. When the pressure of the water gathered in the plastic hose 3 is greater than the closing force of the plastic hose 3, Water flows out of the plastic hose 3 and enters the sewer; when the pressure of the water flow is less than the closing force of the plastic hose 3, the free end of the plastic hose 3 is closed, and the floor drain is in a sealed state.

Embodiment 2

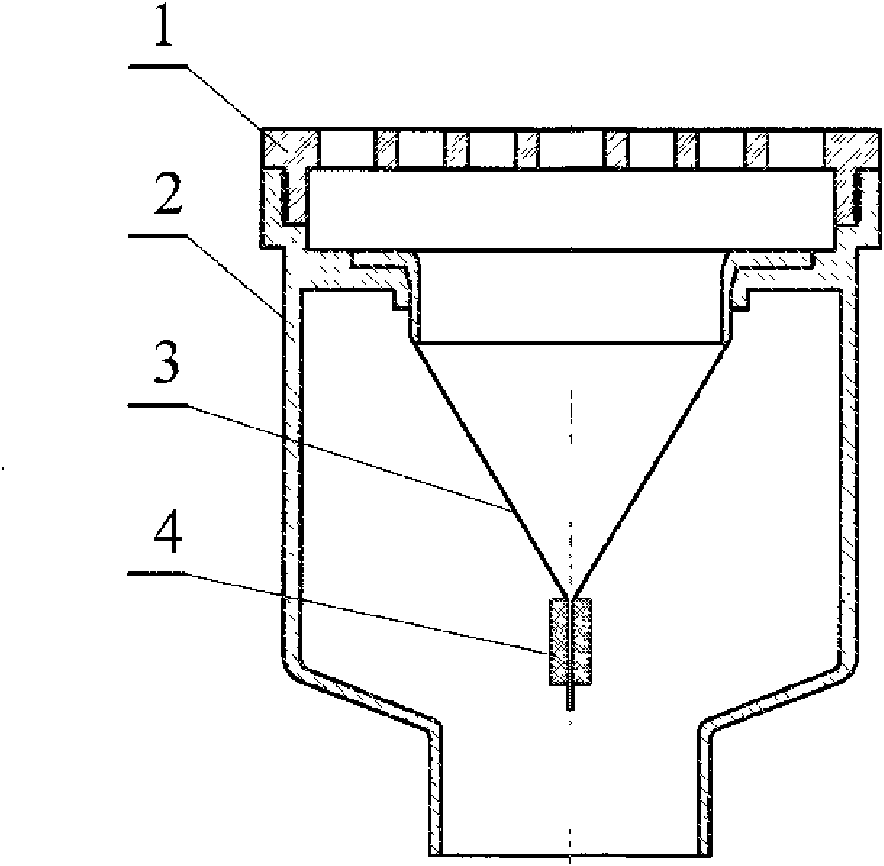

[0012] refer to figure 2 The hose-sealed floor drain is composed of a floor drain cover 1, a floor drain body 2, a plastic hose 3 and a magnetic rubber 4, the floor drain cover 1 is installed on the floor drain body 2, one end of the plastic hose 3 is fixed on the floor drain body 2, and the other end is free end. The magnetic rubber 4 is fixed on the plastic hose 3 by the plastic film heat-sealed on the plastic hose 3 , and the plastic hose 3 is flattened by relying on the magnetic force generated between the magnetic rubber 4 . The water flows into the floor drain body 2 through the floor drain cover 1 and gathers in the plastic hose 3. When the pressure of the water gathered in the plastic hose 3 is greater than the magnetic force between the rubbers 4, the water rushes out of the plastic hose 3 and enters the sewer; If there is always a large water flow through, the plastic hose 3 is always in the open state, the water flow has no resistance, and the solids contained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com