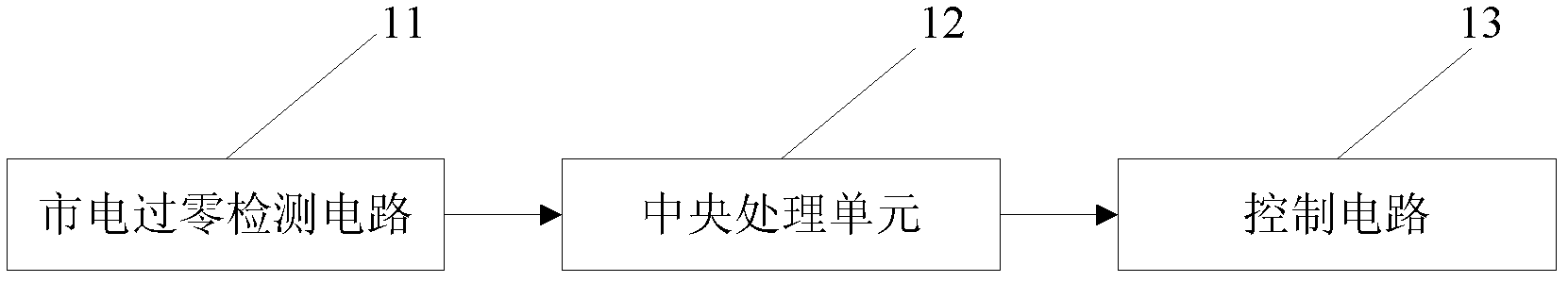

Alternating current heater control device and method

A control device and heater technology, which is applied to auxiliary controllers with auxiliary heating devices, temperature control using electric methods, etc., can solve the problems of inability to reflect advantages, long on-off cycle, high cost, etc., to avoid heating Effects of energy fluctuation, improved reliability, and simple circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

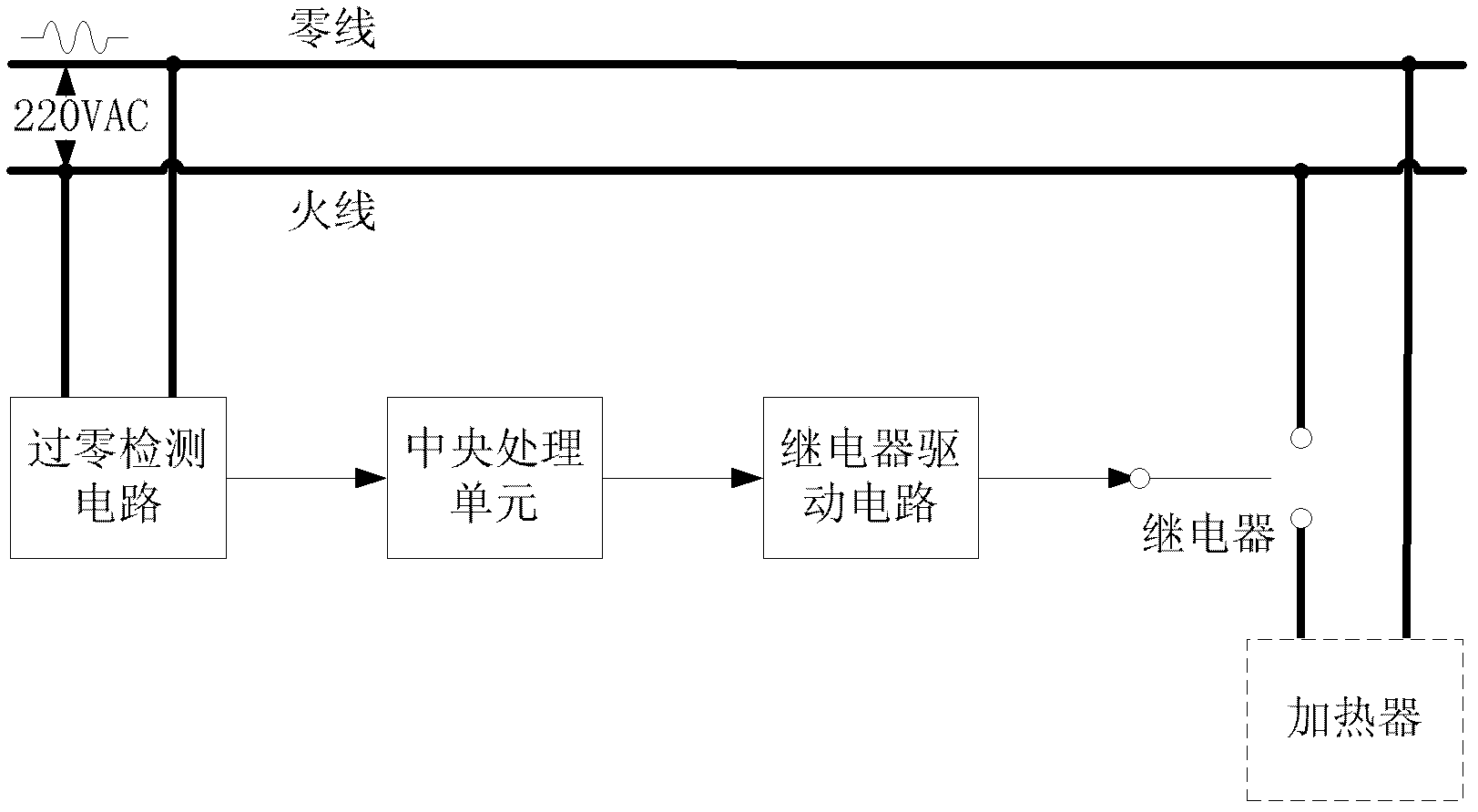

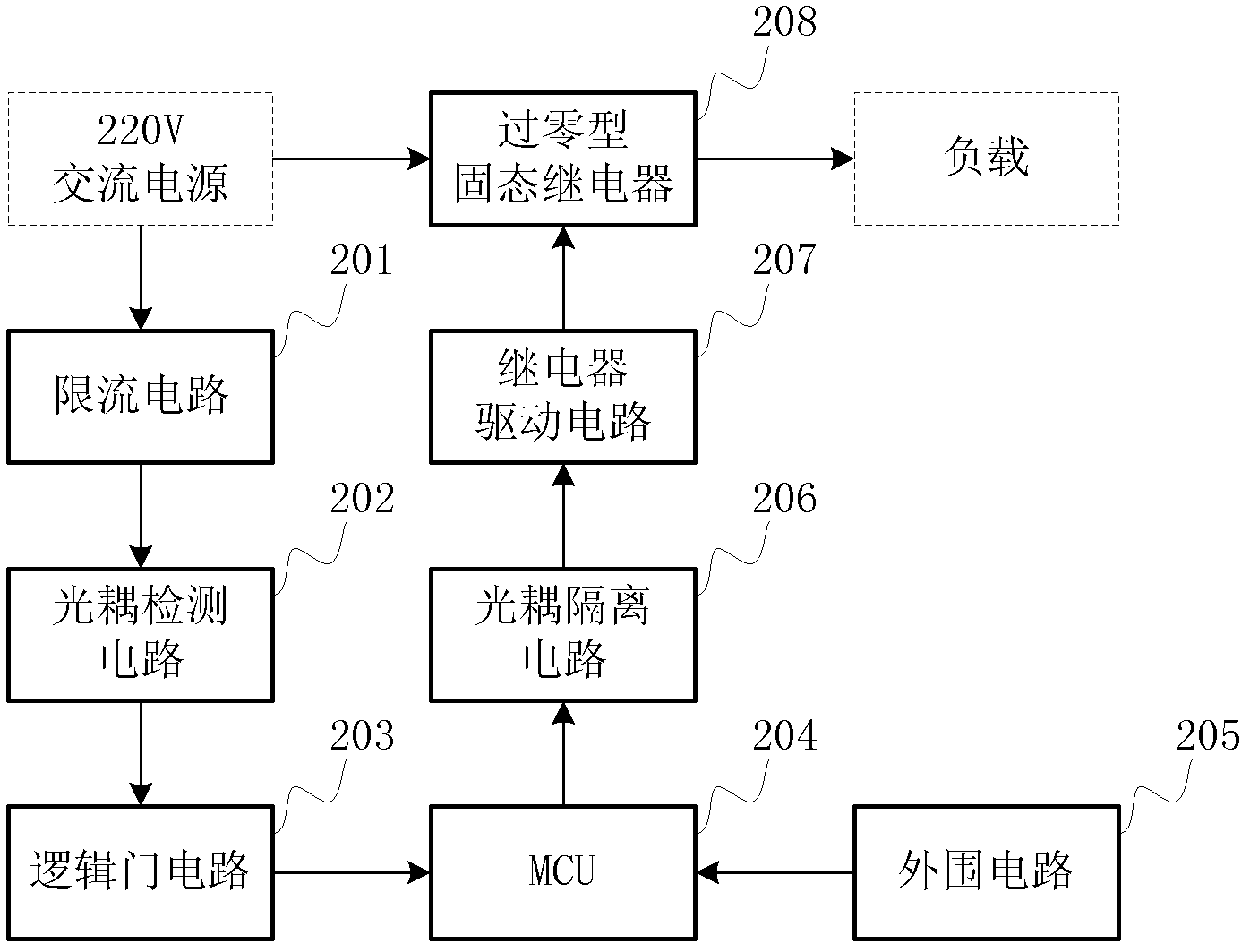

[0066] For the mains zero-crossing period detection circuit 11 of the present invention, the AC signal current limiting circuit 201 provided in this specific embodiment is a direct plug-in resistor. The resistance range of the resistor can be selected from 20KΩ to 100KΩ. The power dissipation of the resistor should be greater than 0.5W. The schematic diagram of the circuit principle of the optocoupler detection circuit 202 provided by the embodiment of the present invention is as follows: Figure 5 As shown, it includes a positive half-period optocoupler detection circuit and a negative half-period optocoupler detection circuit. In the positive half period of the sine wave, when the heater voltage amplitude is close to 0, the positive half-period optocoupler U1 of the optocoupler detection circuit It will cut off and output a high level; in the negative half cycle of the sine wave, when the heater voltage amplitude is close to 0, the optocoupler U2 of the negative half cycle opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com