Wood-plastic base composite floor with solid wood panel and manufacturing method thereof

A technique for composite flooring and a manufacturing method, which is applied in the field of composite boards and its manufacture, can solve the problems of occupying large wood resources, environmental pollution of adhesives, and resistance to wear, and achieve novel and practical structure, environmental protection, and adaptability wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

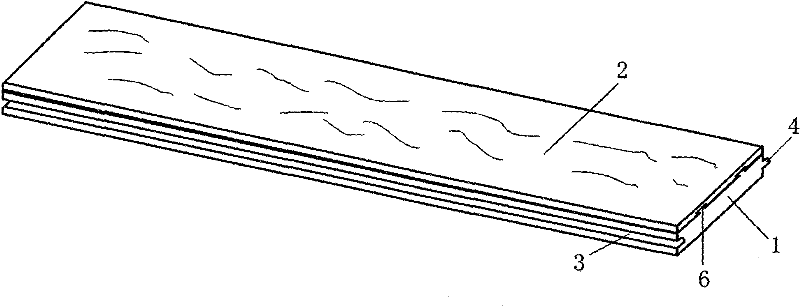

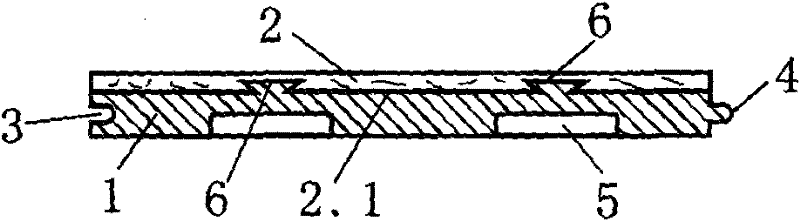

[0029] Embodiment 1: refer to Figure 1 to Figure 4 , in Example 1 of the present invention, such as figure 1 , figure 2 As shown, the above-mentioned panel is a solid wood wood-plastic composite floor, including a substrate 1 and a panel 2, the substrate 1 is a wood-plastic material, the panel 2 is a solid wood board, and the substrate 1 is passed through The injection molding method is connected with panel 2.

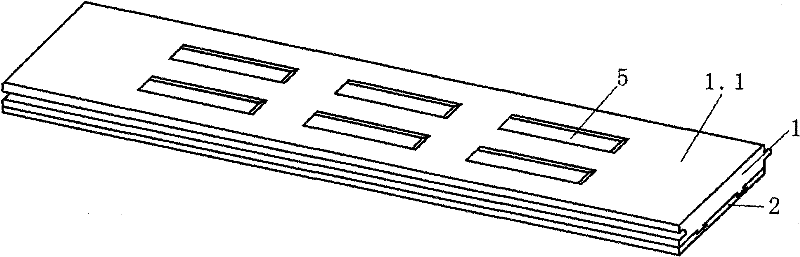

[0030] Such as Figure 1 to Figure 3 As shown, the base plate 1 is provided with a splicing structure along a pair of corresponding sides along the length direction, and the splicing structure includes a groove 3 on one side and a rafter 4 matching the groove 3 on the other side.

[0031] In Example 1 of the present invention, as figure 2 , image 3 As shown, the bottom surface 1.1 of the substrate 1 is provided with a groove 5, and the lower bottom surface 2.1 of the panel is provided with a wedge-shaped groove 6.

[0032] A kind of panel described in embodim...

Embodiment 2

[0044] Embodiment 2: In Embodiment 2 of the present invention, as Figure 5 , Figure 6 As shown, in the manufacture of the panel, the lower bottom surface 2.1 of the panel 2 is inlaid with several light-weight heat-resistant sheets 8 with a total area smaller than the panel area and a thickness smaller than the thickness of the substrate. Between each light-weight heat-resistant sheet 8 If there is a gap, when the injection veneer is formed, the panel 2 inlaid with the light heat-resistant sheet 8 is placed on the upper bottom surface of the inner cavity 7.1 of the injection mold, the injection mold 7 is placed on the injection molding machine, and the granulated The wood-plastic material is placed in the barrel of the injection molding machine. According to the injection molding process, the wood-plastic material is injected into the injection mold 7 and bonded with the panel 2 to form the substrate 1. The injection temperature is 180°C-230°C. In this way, the injection-mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com