Integral large flow check valve

A large flow, one-way valve technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as large flow fluctuations in coolers, cooler bursts, and large flow pressure drops , to achieve the effect of novel and practical structure, preventing large flow and small flow pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the drawings:

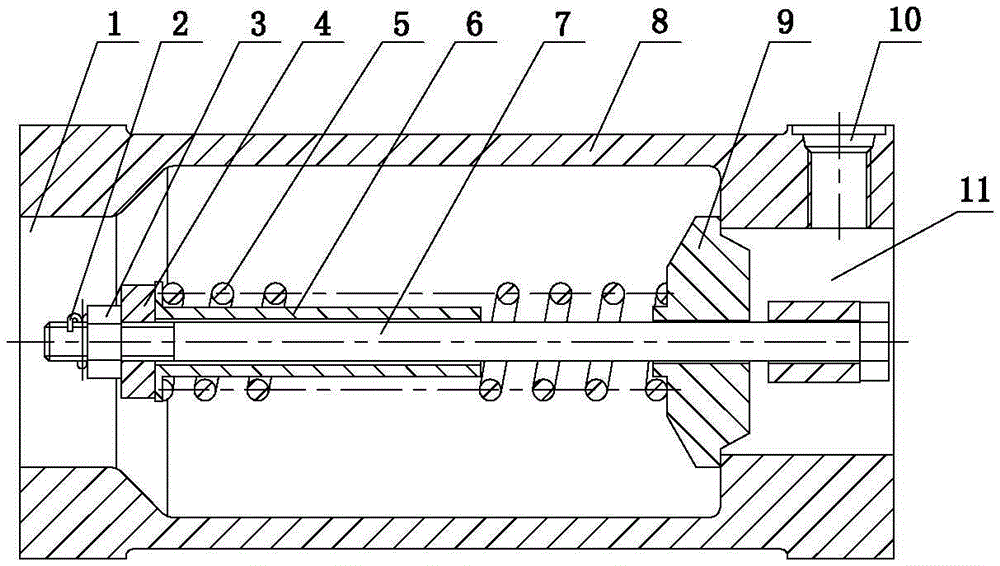

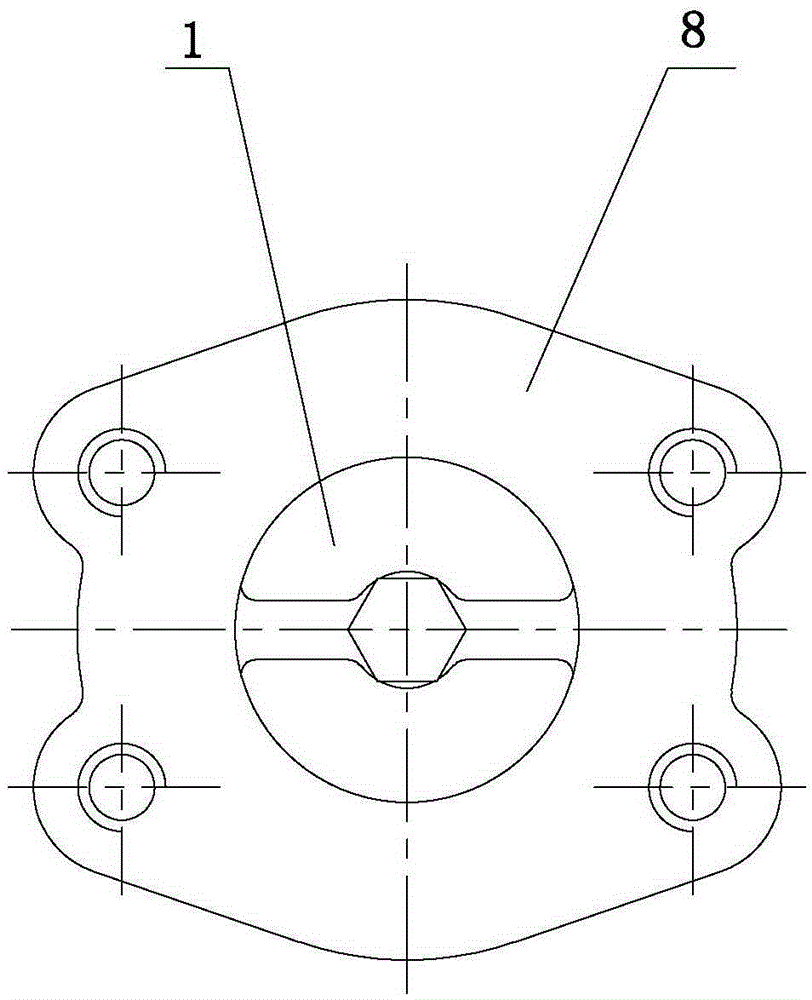

[0013] Such as figure 1 , 2 As shown, the present invention includes a valve body 8 connected to a hydraulic system. One end of the valve body 8 is provided with an oil inlet 11, and the other end is provided with an oil outlet 1. The valve body 8 is provided with a cover plate 9 covering the oil inlet 11, a bolt 7 is installed in the center of the cover plate 9, and a spring 5 is sleeved on the bolt 7, and one end of the spring 5 rests on the cover plate (9). One end is installed outside the support tube 6 which is also sleeved on the bolt 7. At one end of the bolt 7 near the oil outlet 1, a pressure plate 4 for positioning the support tube 6 and an adjusting nut 3 for adjusting the pressure of the spring 5 on the cover plate 9 are provided. The adjusting nut 3 is also used to fix and adjust the opening pressure. A split pin 2 is provided at the end of the bolt 7 to prevent the adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com