Diaphragm type PCV valve

A diaphragm type, diaphragm technology, applied in the direction of diaphragm valves, diaphragms, valve devices, etc., can solve the problems of non-normal closing, easy to produce abnormal noise, poor valve seating, etc., to prolong the service life and reduce the effect of abnormal noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

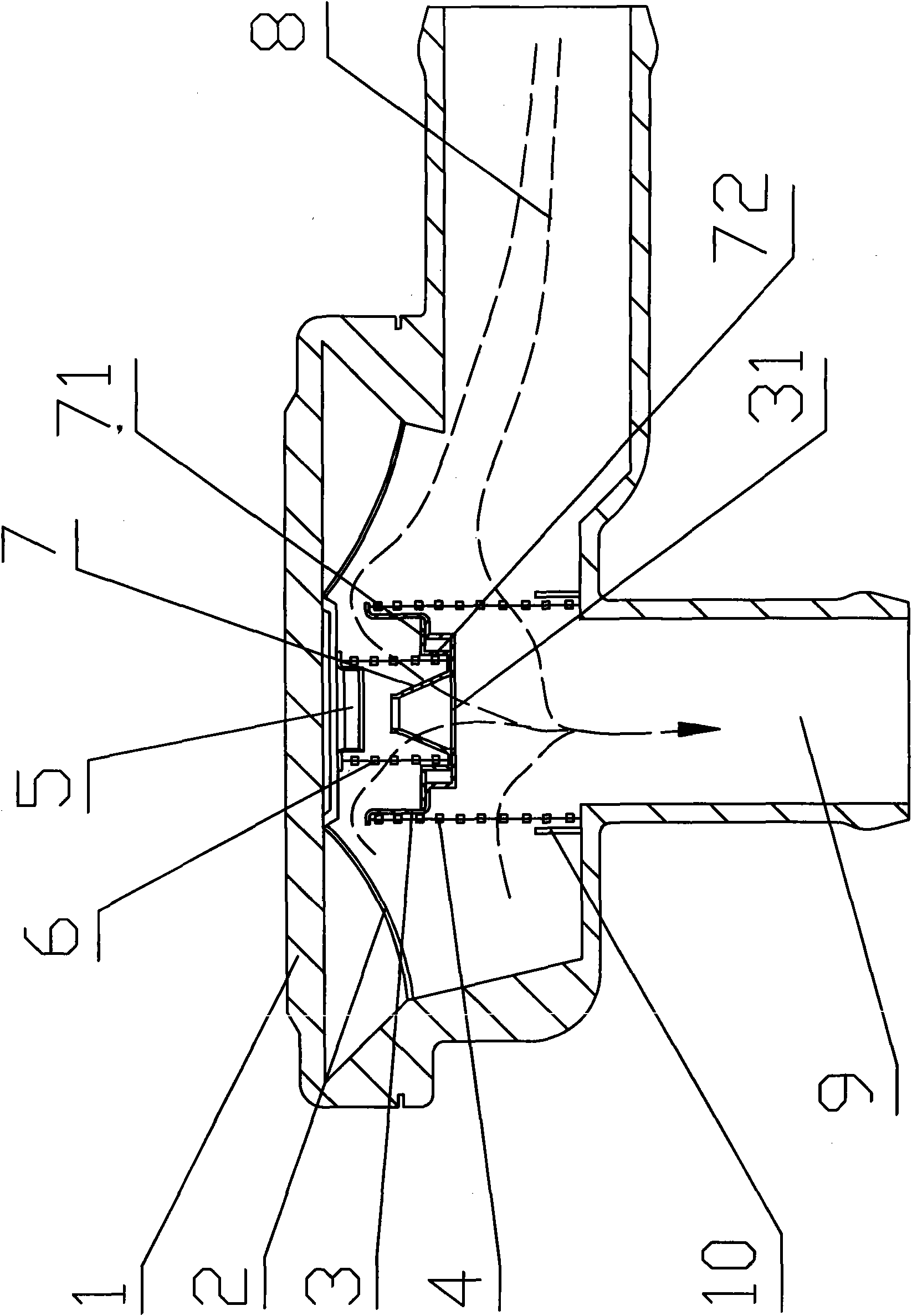

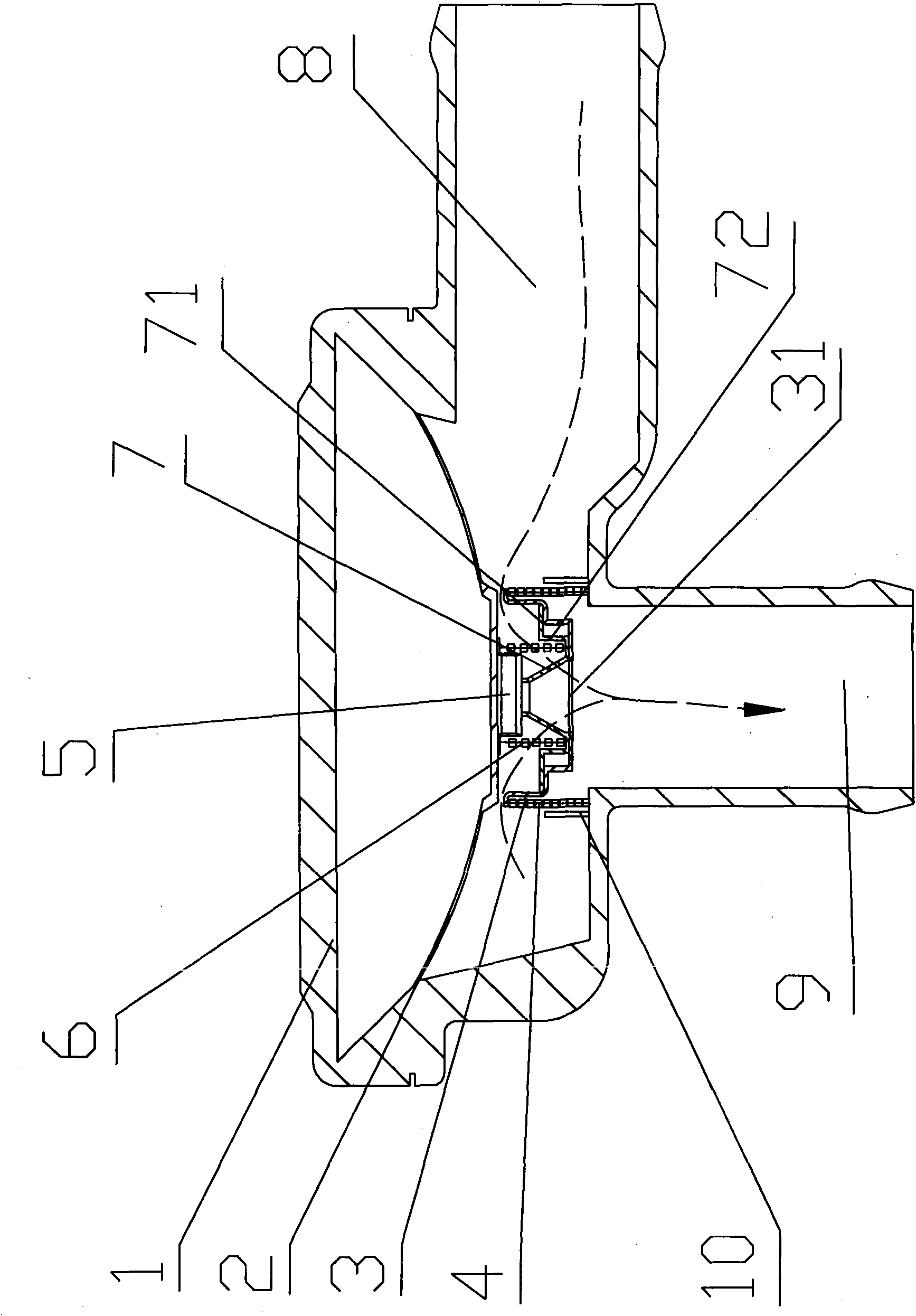

[0018] Such as figure 1 , 2 As shown, the diaphragm PCV valve of the present invention includes a hollow housing 1, a diaphragm 2 is arranged in the cavity of the housing 1, and the housing 1 is respectively opened with Air outlet 9 and air inlet 8, a big spring 4 is fixed on the housing at described air outlet 9 places, and the top of described big spring 4 is connected with the big spring bracket 3 that has through hole 31 at the bottom, and the key is that The diaphragm 2 is fixed with a cylindrical support block 5 corresponding to the position of the large spring support 4, and a small spring 6 is fixed on the outer periphery of the support block 5, and the diameter of the support block 5 is slightly smaller than the diameter of the small spring 6. The difference in diameter is generally 1 to 2 millimeters; the bottom of the small spring 6 is equipped with a small spring support 7, the middle part of the small spring support 7 protrudes upwards and extends into the inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com