Refrigerant system oil accumulation removal

A refrigerant and refrigerant circuit technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as system performance degradation, evaporator efficiency reduction, and HVAC system cost increase, to avoid wear problems and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

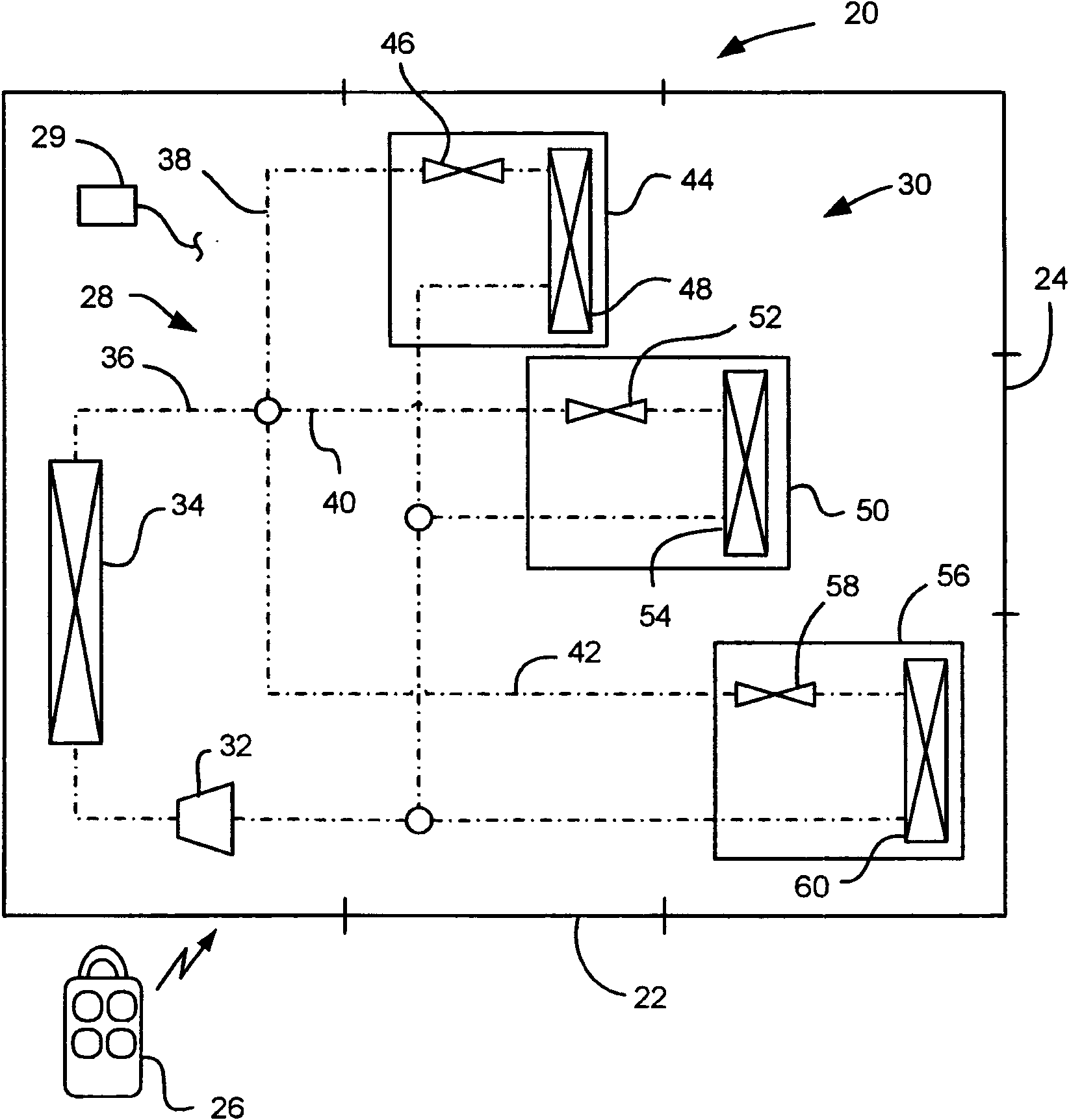

[0016] refer to figure 1 , a vehicle generally indicated at 20 is shown. The vehicle 20 includes doors 22 and may include a hatch 24 or a key fob 26 (or other keyless entry system). Vehicle 20 also includes a heating, ventilation and air conditioning (HVAC) system 28 controlled by controller 29 .

[0017] The HVAC system 28 includes a refrigerant system 30 having a compressor 32, a condenser 34, and a plurality of refrigerant circuits connected by refrigerant lines 36 that direct refrigerant through the various components. The refrigerant contains oil, which flows with the refrigerant to provide lubrication to the compressor 32 . figure 1 The exemplary embodiment shown includes three refrigerant circuits: a front refrigerant circuit 38 , a rear (also referred to as auxiliary) refrigerant circuit 40 , and a battery refrigerant circuit 42 . The front refrigerant circuit includes a front HVAC module 44 having a front expansion device 46 and a front evaporator 48 . The post re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com