Fiber Bragg grating measuring method of deflection of travelling crane

A technology of grating measurement and optical fiber, which is applied in the direction of measuring device, elastic test, machine/structural component test, etc. It can solve the problems of wasting manpower, wrong observation results, time-consuming and labor-intensive measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

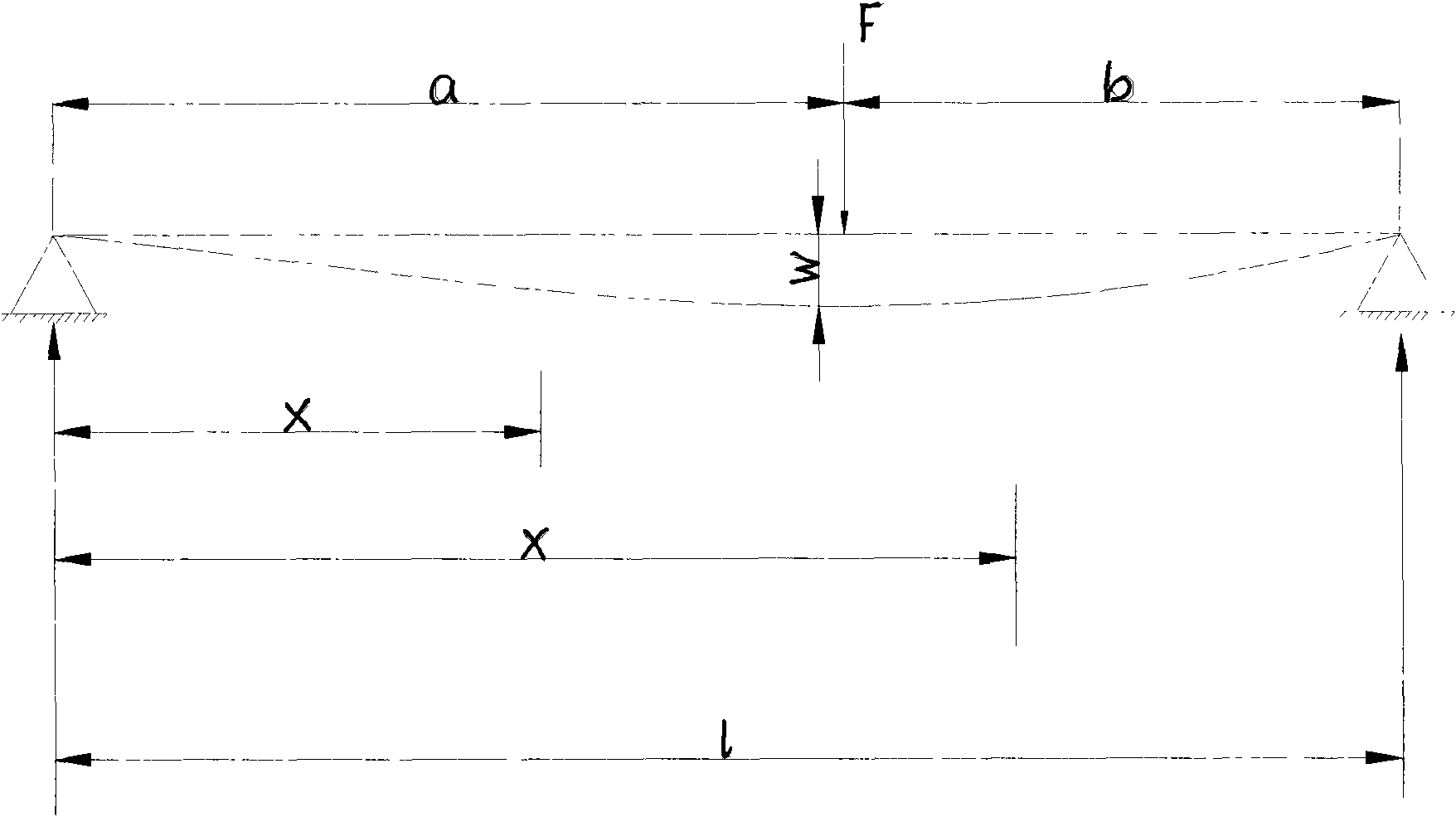

[0035] The following embodiment is the example that the inventor adopts the optical fiber Bragg grating to measure the deflection of the vehicle in the laboratory, and is the example carried out by the inventor in the laboratory, and its experimental parameters are:

[0036] 1. Dimensions of the main beam of the vehicle: choose 10# I-beam with a length of 1m as the main beam of the vehicle, the span l=1000mm, the waist height (h) is 100mm, the leg width (t) is 68mm, and the waist thickness (d) is 4.5mm ;

[0037] 2. The main beam of the train, the material parameters are: the Young’s modulus of 45# steel is E=200GPa;

[0038] 3. The technical parameters of the fiber Bragg grating are: central wavelength λ B =1550.000nm, effective elastic-optic coefficient p e =0.22;

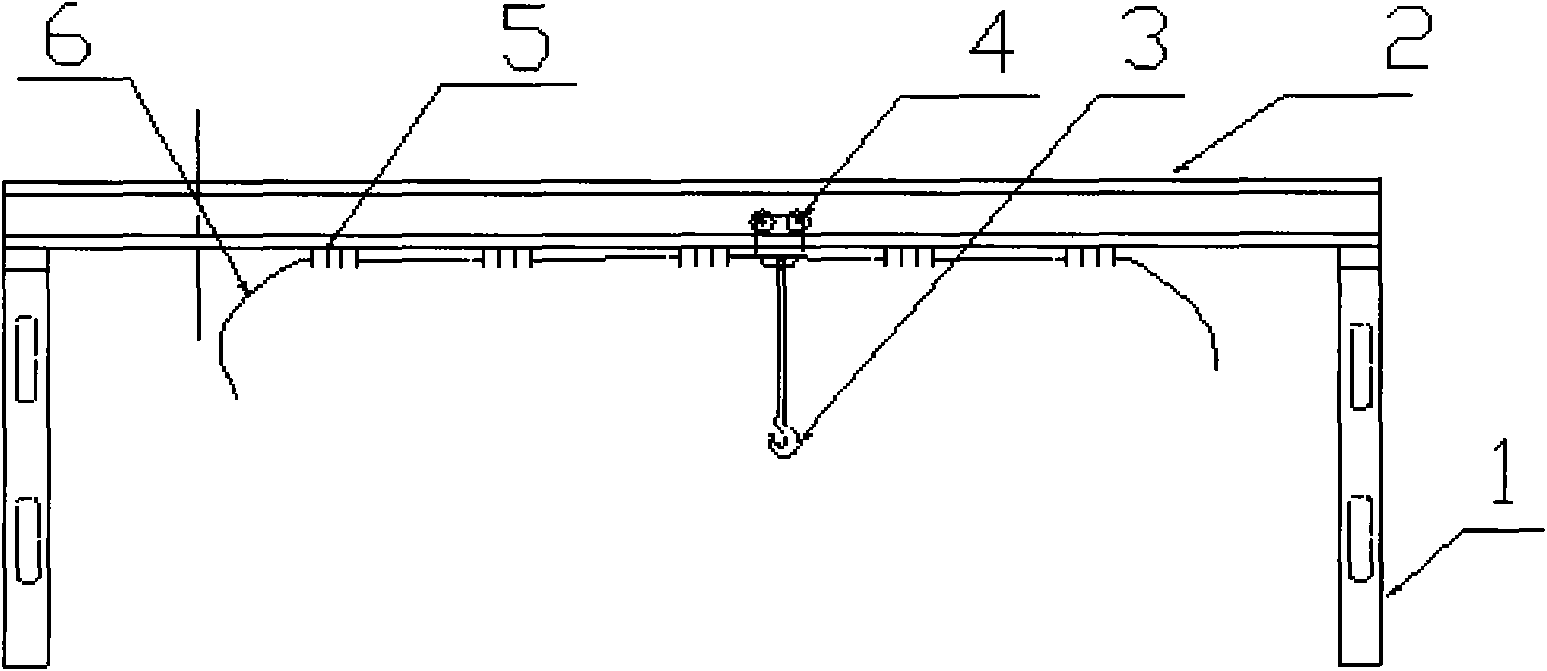

[0039] 4. Attached figure 1 For the configuration experiment, 5 measuring points are respectively set at 1 / 6, 2 / 6, 3 / 6, 4 / 6, and 5 / 6 from the left end of the main beam (2);

[0040] 5. Use a fiber grating an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com