Tertiary air addition to solid waste-fired furnaces for nox control

A secondary air and combustion furnace technology, applied in the direction of combustion air/fuel supply, combustion type, combustion equipment, etc., can solve the problems of high capital cost and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

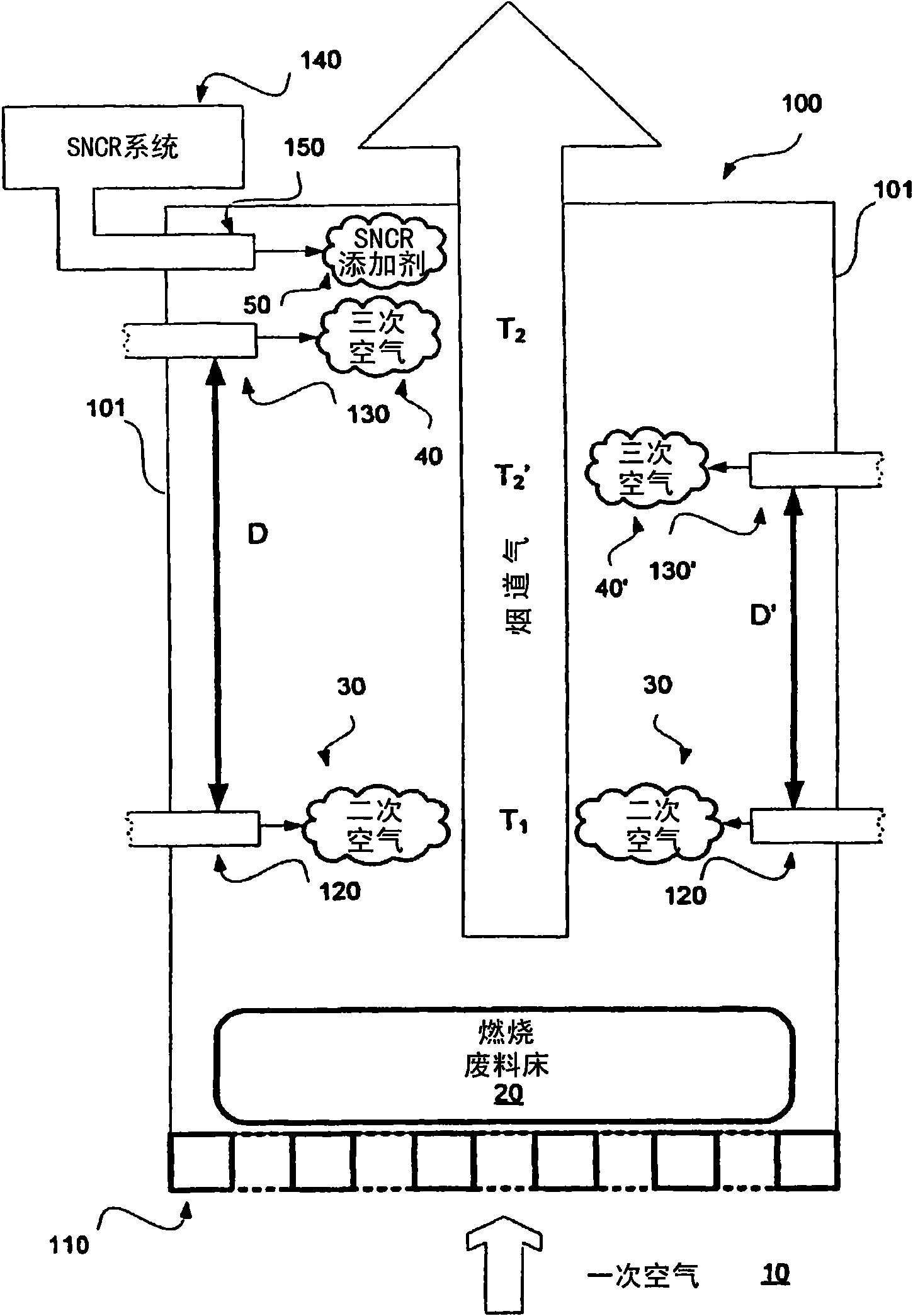

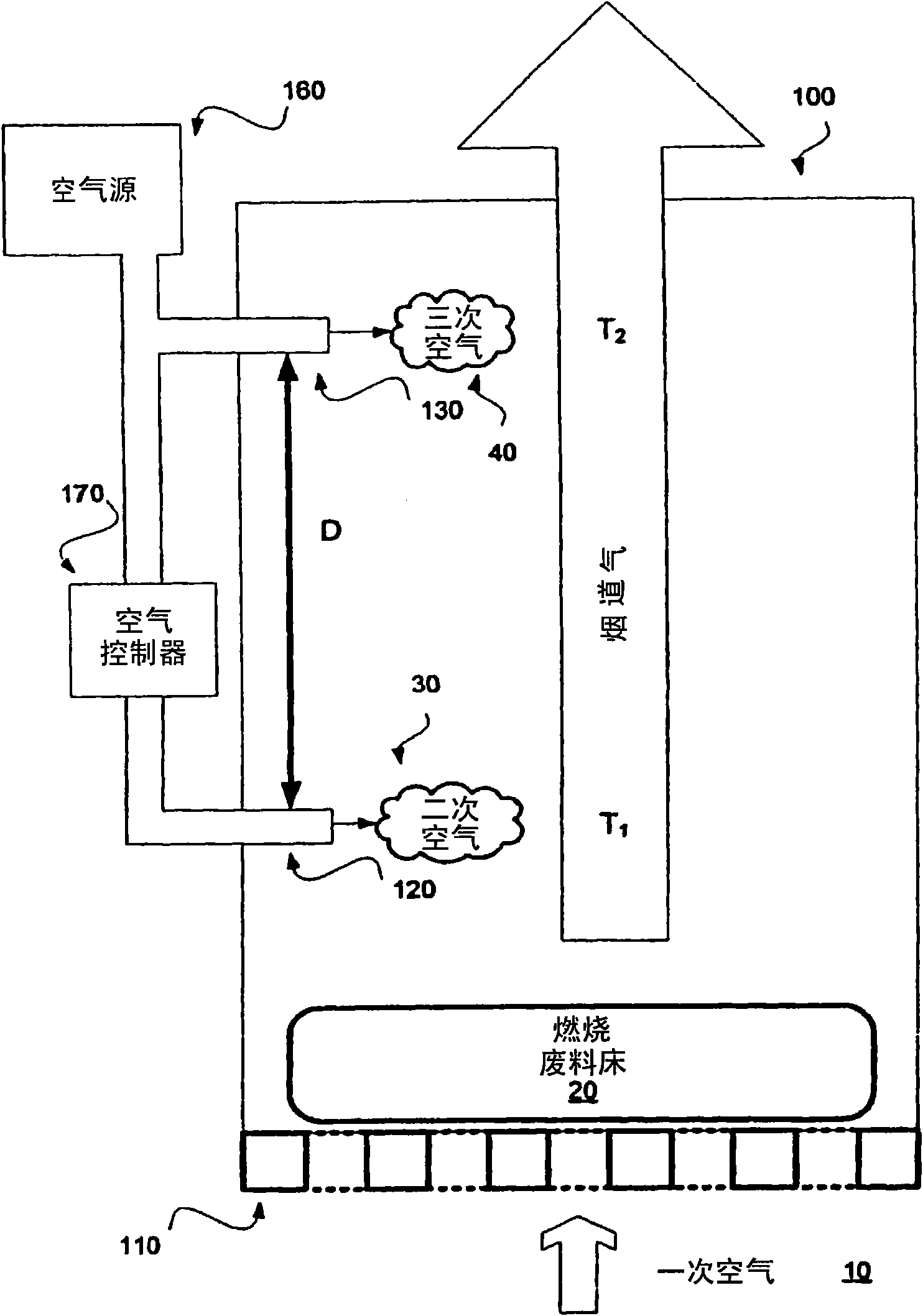

[0029] now refer to figure 1 , in one embodiment of the present invention, the solid waste combustion system 100 utilizes a moving grate 110 having three primary sources of combustion air. Primary air 10 is introduced below the grate 110 and flows upwards through the bed of combustion waste 20 . Secondary air 30 is introduced through one or more rows of secondary nozzles 120 above the bed of combustion waste 20 . In a typical MWC, secondary air 30 is used to vigorously mix the combustion gases by adding additional oxygen and providing turbulence to complete the combustion of VOCs and carbon monoxide as quickly as possible. In the present invention, secondary air plays a different role. Secondary air is injected at a low rate to minimize mixing and combustion. The role of the secondary air is to promote the concentration of the flame in the furnace and to create a cooler air blanket along the wall, thereby reducing the effect of higher furnace temperatures on the materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com