Electrical connections for plastic panels having conductive grids

A technology for electrical connectors and panels, which is applied in the field of connection of plastic panels, and can solve problems such as spring contacts becoming loose, heating grids not working, unacceptable bonding strength and/or reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following description of the preferred embodiment is exemplary only in nature and is in no way intended to limit the scope of the invention or its application or uses.

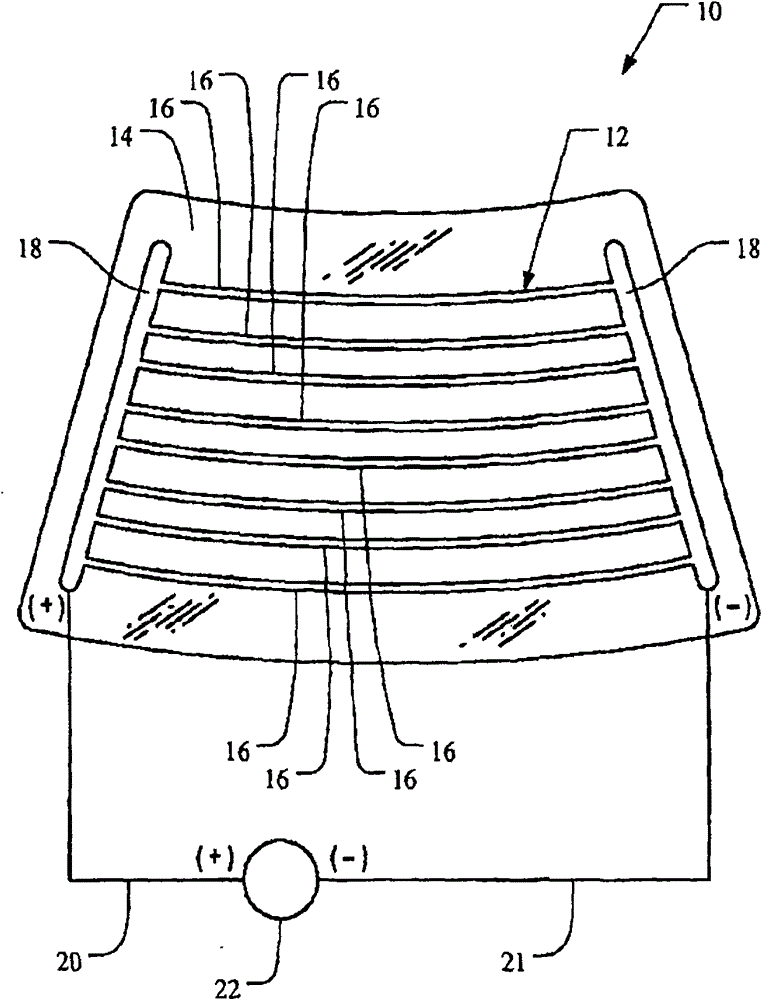

[0049] now refer to figure 1 , which generally illustrates a plastic window or body panel system 10 comprising, as its main component, a conductive grid 12 disposed on a panel 14 . Conductive grid 12 may be one of a variety of elements that provide functionality to window system 10 . Thus, the conductive grid can be an antenna well known in the art, an electroluminescent border, a heat generating grid, and a device like an electrochromic device, a photochromic device, a liquid crystal device, a user-controllable photochromic device, a polymer dispersed liquid crystal One of the color rendering devices such as devices and suspended particle devices. However, for convenience, the conductive grid is generally described herein as the heat generating grid 12 .

[0050] The heat generating grid 12 pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com