Locomotive cab steel structure flexible assembly jig

A locomotive driver, steel structure technology, applied in auxiliary equipment, railway car body, transportation and packaging, etc., can solve problems such as difficult to ensure assembly quality, energy, material consumption, component surface damage, etc., to adapt to mass assembly The effect of production, reduction of repetitive labor, improvement of assembly quality and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

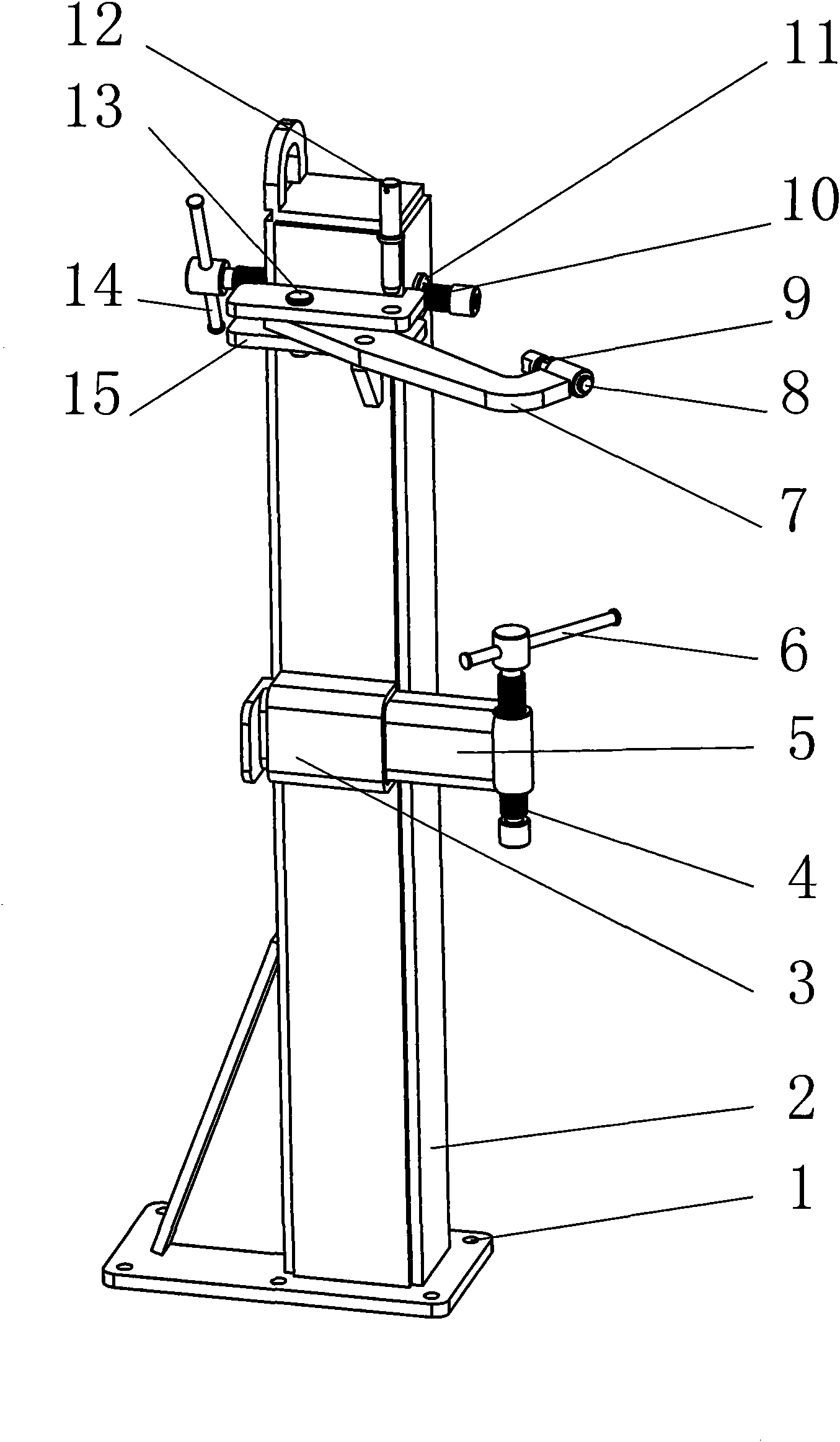

[0008] see figure 1 , The positioning column (2) in this embodiment is provided with positioning bolt holes (1) on its base. The top shaft (10) of the clamping structure is laterally protruded from the upright column (2) in a threaded manner. 7) and the pin seat (15) are provided with corresponding positioning pin holes and positioning pins (12), the hook end of the hook arm (7) is provided with a positioning bolt (8), and the positioning bolt (8) is provided with a locking nut ( 9). The sleeve seat (3) of the compression structure is fixed on the upright column (2), the short beam (5) is inserted into the sleeve seat (3), and can move laterally in the sleeve seat (3). There is a vertical threaded top shaft (4), and the upper end of the top shaft (4) is provided with a rotating handle (6).

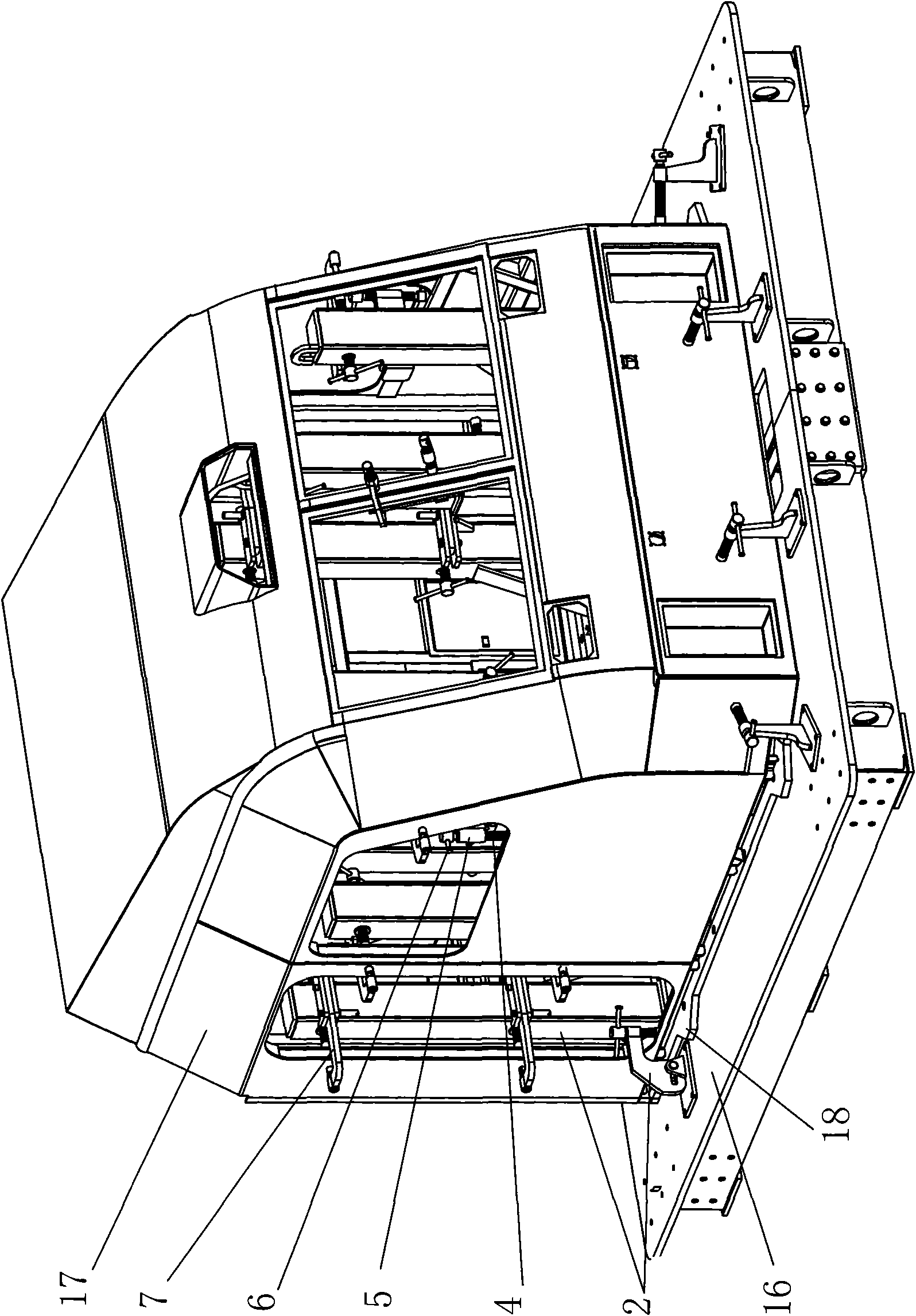

[0009] According to the difference of the actual position, the height of the positioning column will be different, and the angle of the clamping structure and the pressing structure on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com