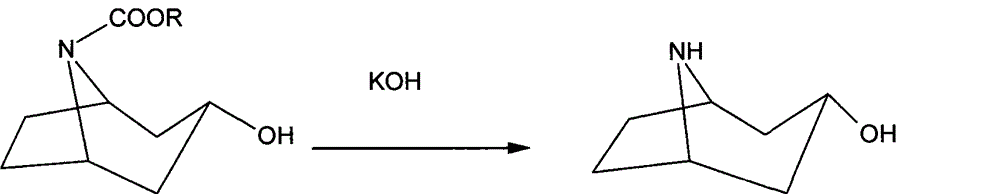

Method for preparing nor-tropine

A technology of nortropine alcohol and potassium hydroxide, which is applied in the new preparation field of nortropine alcohol, can solve the problems of difficulty in organic solvent extraction, increase the difficulty of extraction, and low solubility, so as to save consumption, reduce dosage, The effect of saving solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are preferred embodiments of the present invention, but the protection scope of the present invention is not limited thereto.

[0022] 1, in the autoclave of 1000 liters, draw in the potassium hydroxide aqueous solution (163kg (90%) potassium hydroxide adds 740kg water) that prepares. Then pump in 100kg of liquid N-ethoxycarbonylnortropine alcohol at about 70°C, stir and mix well, vacuumize, and then fill with nitrogen to 2-3kg / cm 2 , then stir and mix, vacuumize, and release nitrogen to 1kg / cm 2 .

[0023] Turn on the stirring, heat the steam to about 150°C, keep the heat for 1 hour, and gradually increase the pressure in the kettle to 8kg / cm 2 , open the vent valve to reduce the pressure to 4kg / cm 2 About 5 hours at 150°C for 5 hours, during which the pressure will rise to 5kg / cm 2 . After the reaction is complete, open the vent valve to reduce the pressure to normal pressure, pass circulating water to cool down to 60°C, and take a sample for testin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com