Piecewise heat treatment method of large pressure container

A heat treatment method and pressure vessel technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of easy deformation of large pressure vessels, achieve good heat treatment effects, reduce furnace construction costs, and increase heat treatment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

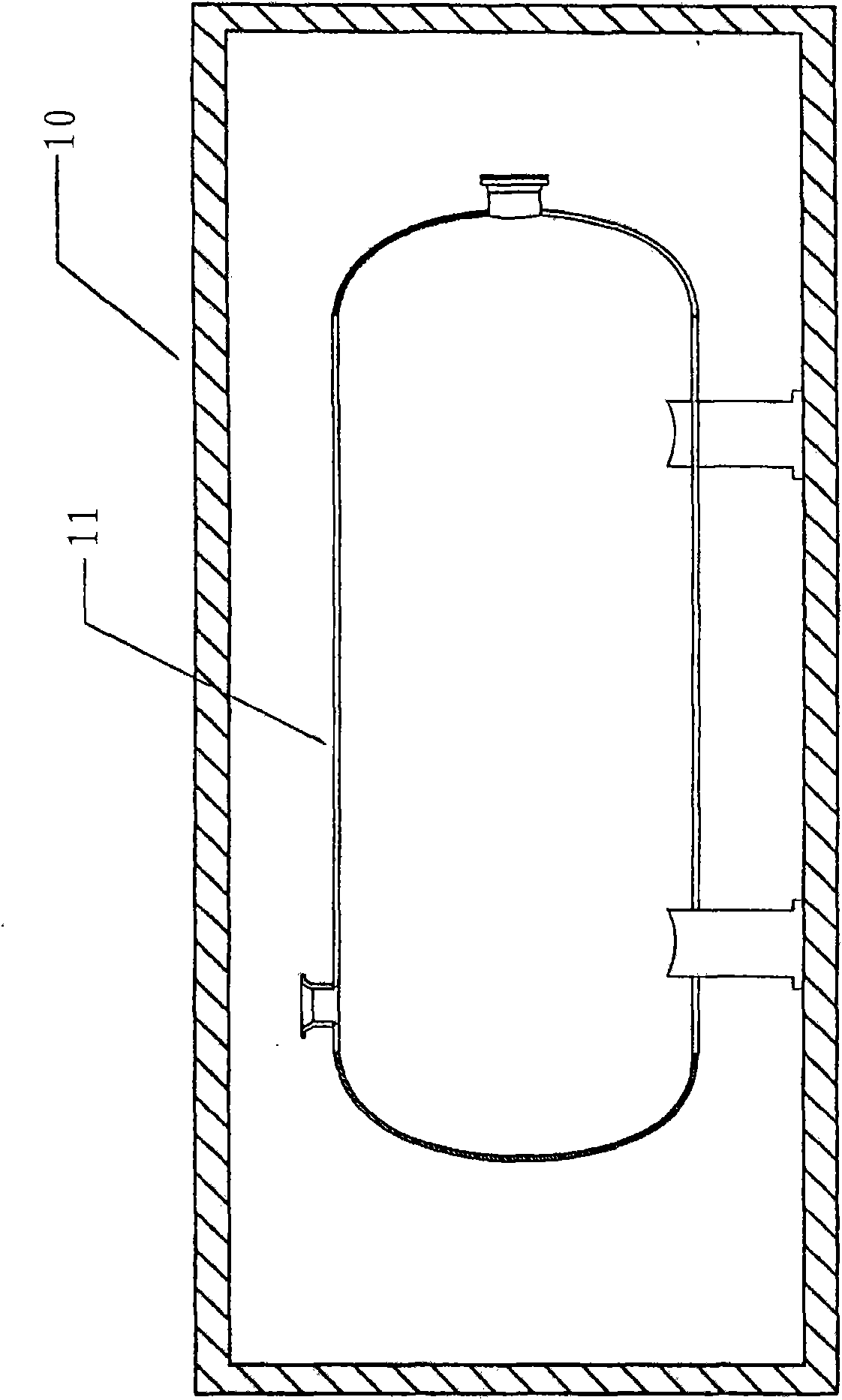

[0034] The large pressure vessel of the present invention refers to an integral pressure vessel that cannot be transported on roads, and the diameter of such a pressure vessel is usually equal to or greater than 4 meters.

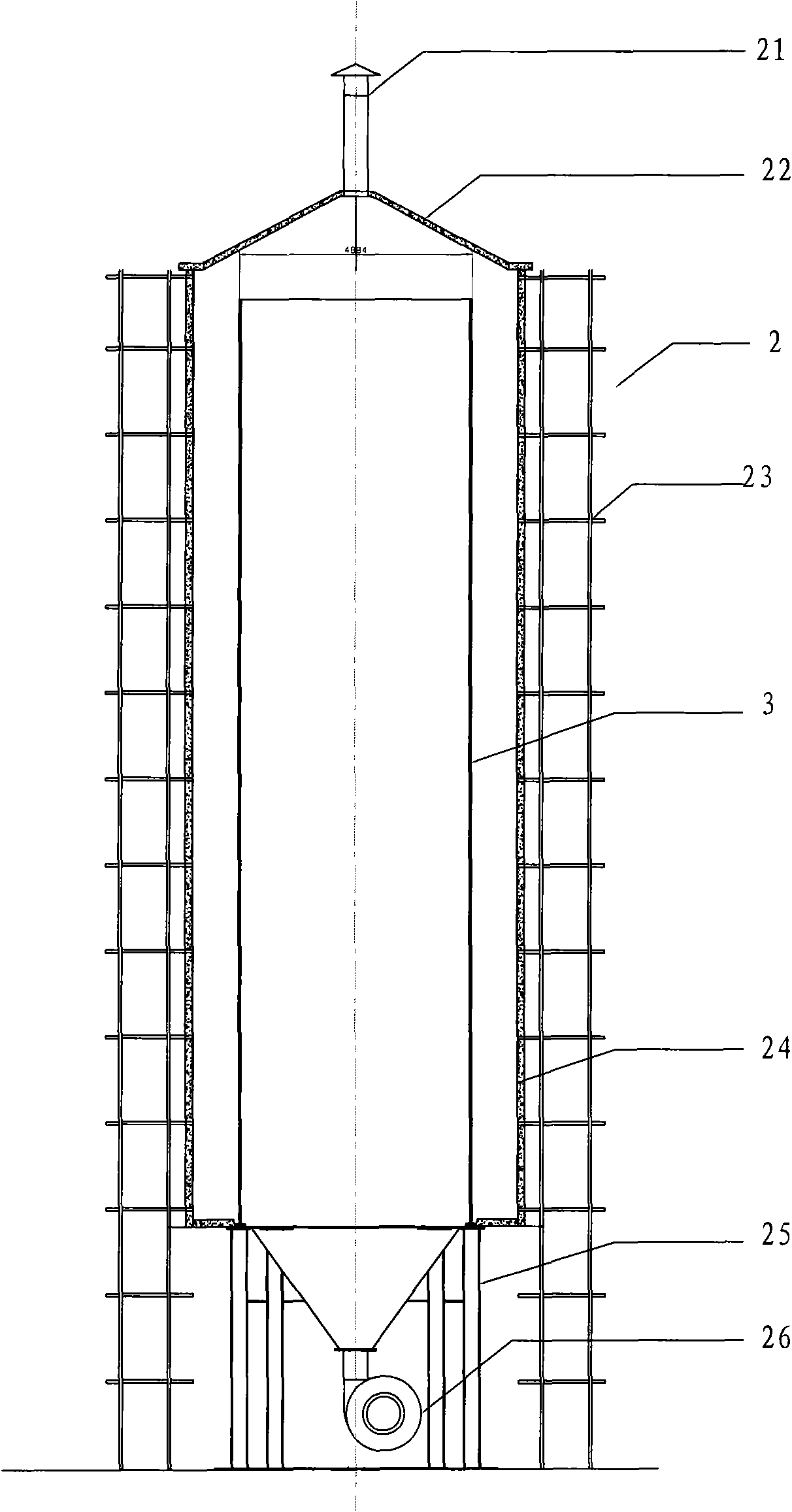

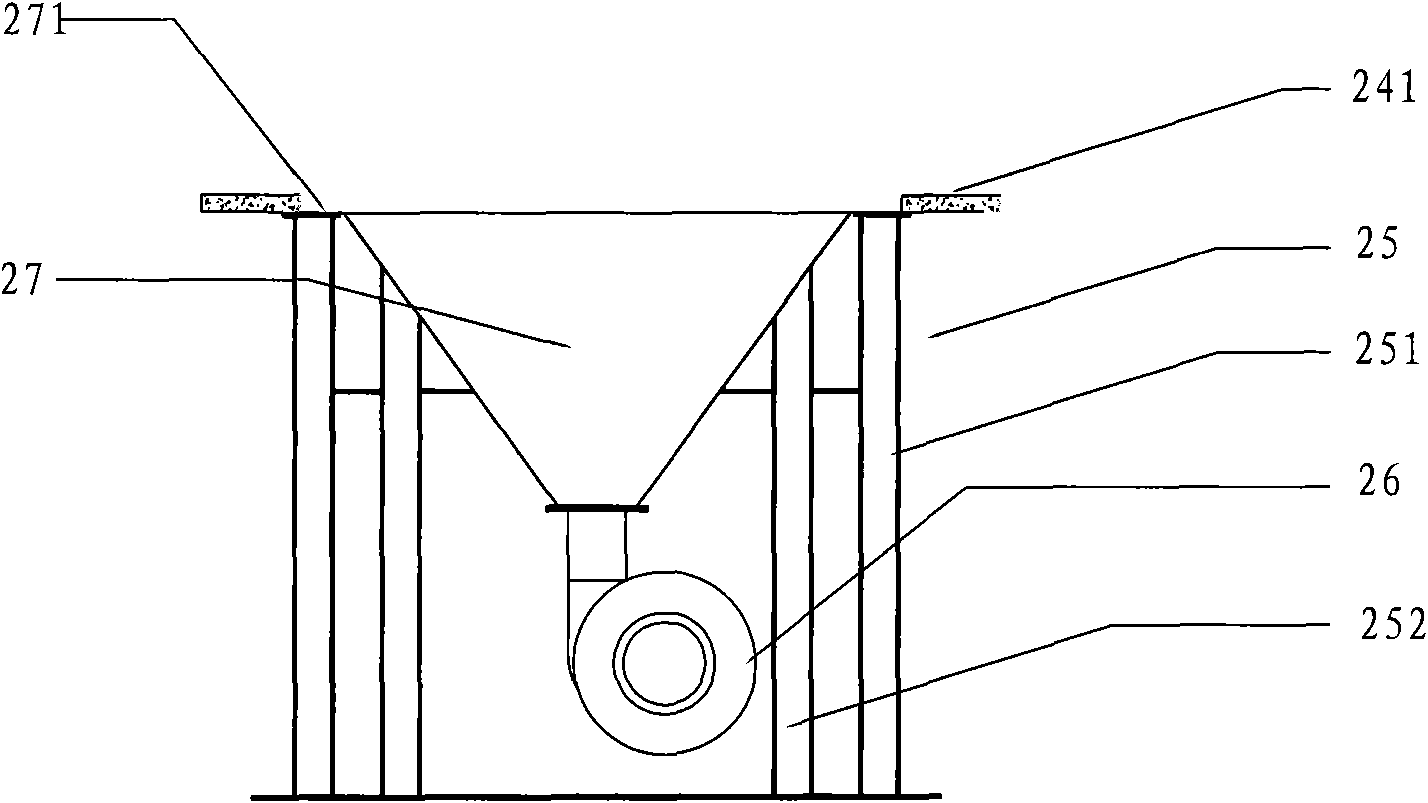

[0035] figure 2 The staged heat treatment method of a large pressure vessel of the present invention is shown. Due to the large size of large pressure vessels, manufacturing plants usually build large pressure vessels in sections, and then transport the sections of the sectioned pressure vessels to the installation site. Since each section of a large pressure vessel is a circular cylinder, for the sake of convenience of description, the present invention refers to a section of a large pressure vessel as a pressure vessel section (or pressure vessel cylinder) 3 .

[0036] Such as figure 2 Shown, the staged heat treatment method of large pressure vessel of the present invention comprises the following steps:

[0037] Construction of a temporary firing fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com