Stainless steel reed beam for weaving machine

A technology of stainless steel and reed beams, applied in the fields of reed beams for looms and stainless steel reed beams for looms, can solve the problems of inconvenient processing, improve straightness and tensile strength, be easy to process, and increase the contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

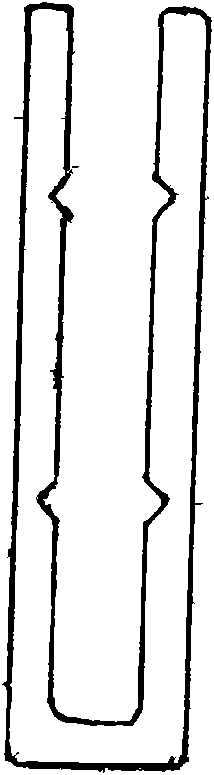

[0012] As shown in Figure 1, after leveling the cut stainless steel strip with a length of 45cm, respectively open a 0.5cm deep section with a right-angled triangle on the surface of the steel strip at a distance of 5cm and 13cm from the side of the stainless steel strip. Groove; According to the reed processing size requirements, draw a bending line on the surface of the stainless steel strip 20cm away from the side, and open a 0.4cm deep equilateral right-angled triangle longitudinal bending gap with this bending line as the center; At the bending gap, perform 6 consecutive bendings from outside to inside, each time the bending angle is kept at 15°, until the cross section is U-shaped; finally, straightening and surface treatment are carried out.

[0013] The present invention is not limited to the embodiment described in detail above, and various modifications can be made without departing from the gist of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com