Measuring device and measuring method of raceway position of large slewing bearing

A technology of slewing ring bearings and measuring devices, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc. It can solve the problems that the deviation value cannot be read quantitatively, the light transmission method cannot be used to detect, and the requirements for position and dimension deviation are very high. To achieve the effect of production quality control, high measurement accuracy and stability, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

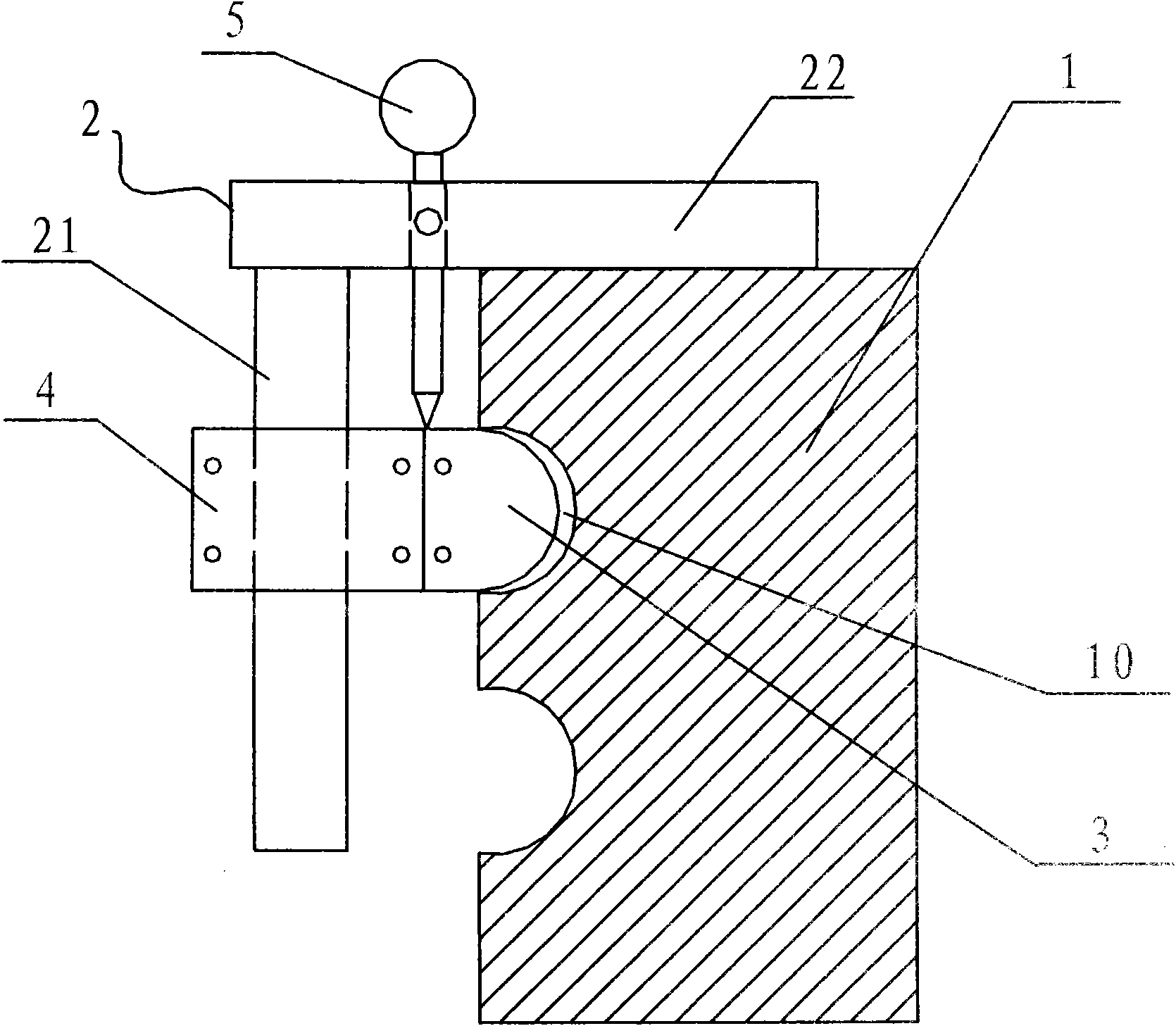

[0019] see figure 1 , The outer surface of the inner ring and the inner surface of the outer ring of the slewing support bearing 1 are respectively provided with single-row or double-row grooves 10, and the inner ring and outer ring of the bearing 1 are combined to form a steel ball raceway for assembling steel balls.

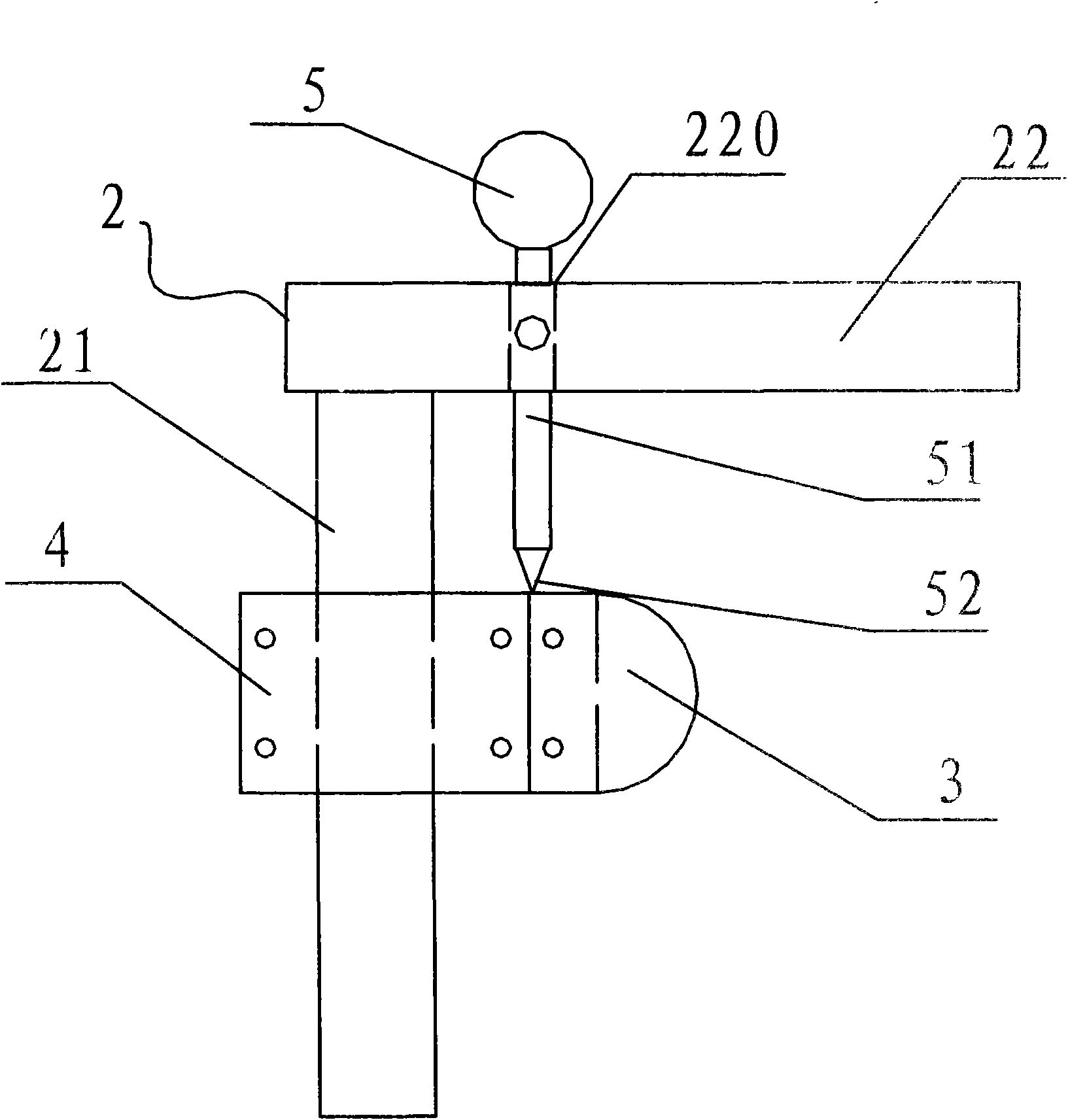

[0020] The measuring device of the raceway position of the large slewing support bearing of the present invention comprises a square 2, a template 3, a slide rule 4 and a dial indicator 5, wherein,

[0021] The square 2 has a vertical portion 21 and a horizontal portion 22 connected to the upper end of the vertical portion 21, the vertical portion 21 of the square 2 is marked with a scale on the surface, and the end surface of the horizontal portion 22 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com