On-line monitoring method of cold rolled heating furnace roller running state

A technology of operating state and heating furnace, which is applied in lighting and heating equipment, vibration measurement in solids, furnaces, etc., can solve problems such as inability to accurately monitor the operating state of furnace rollers, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

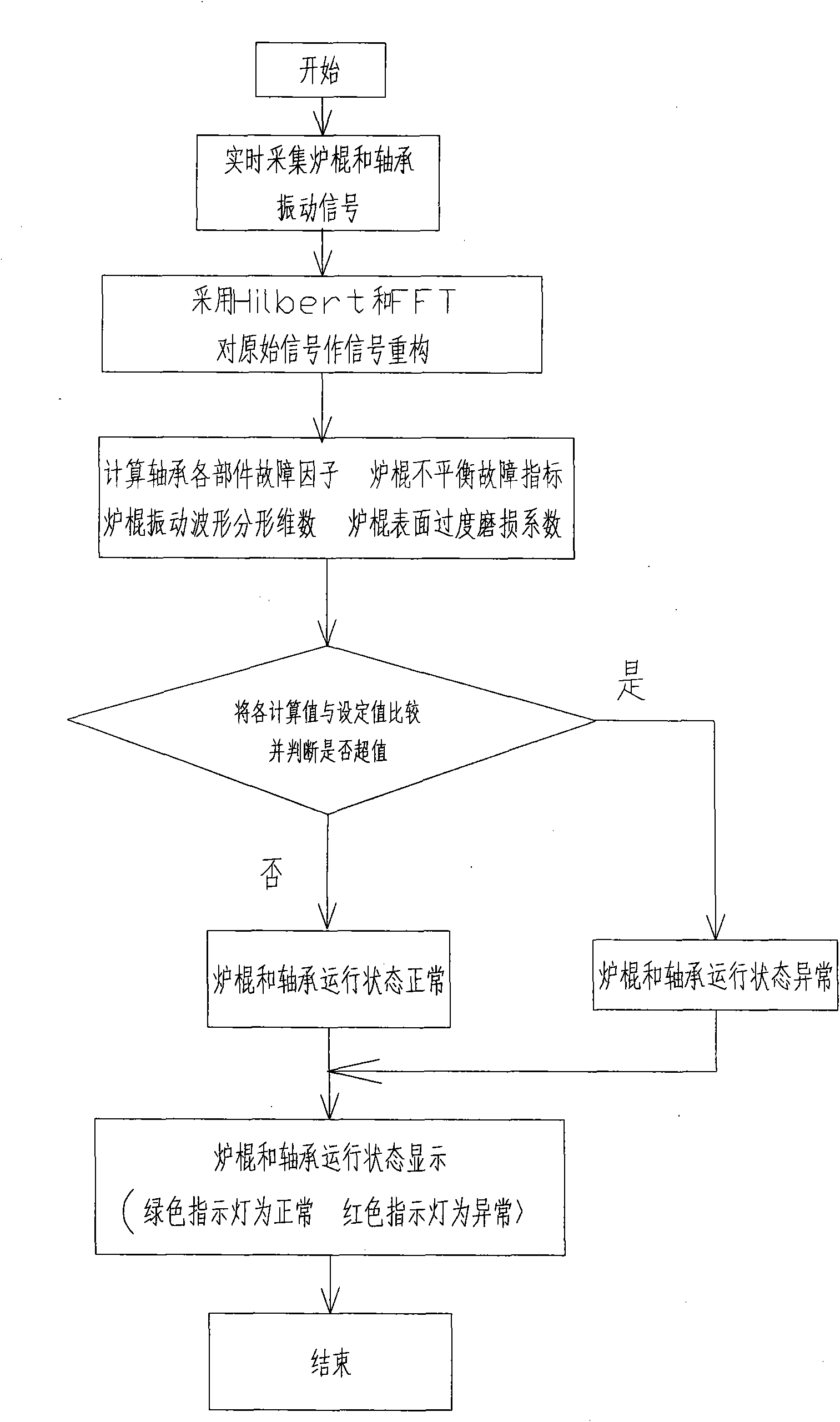

[0039] The core of the present invention is to propose a method for online monitoring of the operating state of the furnace roll, by collecting the vibration parameters of the furnace roll and bearings, obtaining the characteristic parameters of the furnace roll state through signal reconstruction, and using classification indicators to monitor the operating state of the furnace roll and bearings The deterioration trend of the equipment guides the operation and equipment management personnel to take countermeasures to avoid unplanned downtime of the equipment caused by the failure of the bearing and the furnace roll body, and to support the normal production of the cold rolling production line.

[0040] The failure form of the furnace roll is mainly manifested as bearing failure, bending down of the furnace roll, local bulging, cracking of the inner and outer rings, excessive wear, shedding of refractory materials on the surface of the furnace roll, and scaling in the inner cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com