Surge protector

A surge protector and electrode technology, applied in the direction of overvoltage protection resistors, varistors, etc., can solve problems such as cracks in semiconductor chips, insufficient solder flow, and reduced life, and achieve local overheating and conductive cross-section The effect of increasing and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

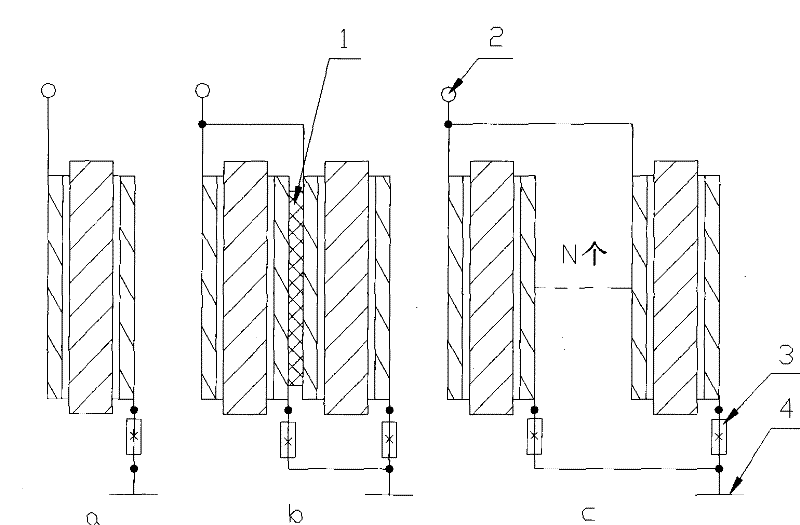

[0010] exist figure 1 Among them, a is the schematic diagram of the surge protector SPD circuit with only one semiconductor chip; b is the schematic diagram of the surge protector circuit with two semiconductor chips; c is the schematic diagram of the surge protector circuit with n semiconductor chips.

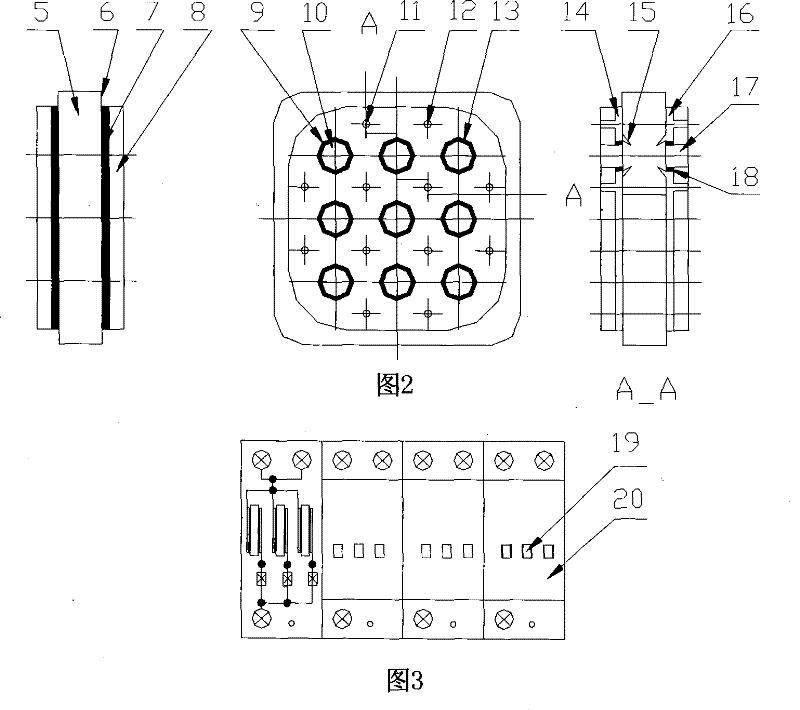

[0011] exist figure 2 Among them, the gap (14) is the gap that appears after the electrical connection surface (6) of the semiconductor chip and the electrode (8) are welded; the crack (15) is the crack that appears after the welding surface of the semiconductor chip (5) and the electrode (8) shrinks after cooling; The conductive solidified liquid (16) is the conductive solidified liquid injected into the gap and crack between the electrical connection surface (6) of the semiconductor chip and the electrode surface, and the conductive solidified liquid (17) is the hole for welding the unwelded surface (6) of the semiconductor chip and the electrode. (13) The conductive solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com