Insulation device for high-voltage outlet terminal of dry-type transformer

A technology of dry-type transformers and high-voltage outlets, which is applied in the direction of transformers/inductor coils/windings/connections, etc., which can solve problems such as poor adaptability to harsh environments, spider web short-circuit power outages, and hidden dangers to improve safety and security. Improve hidden dangers and reduce the effect of space insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

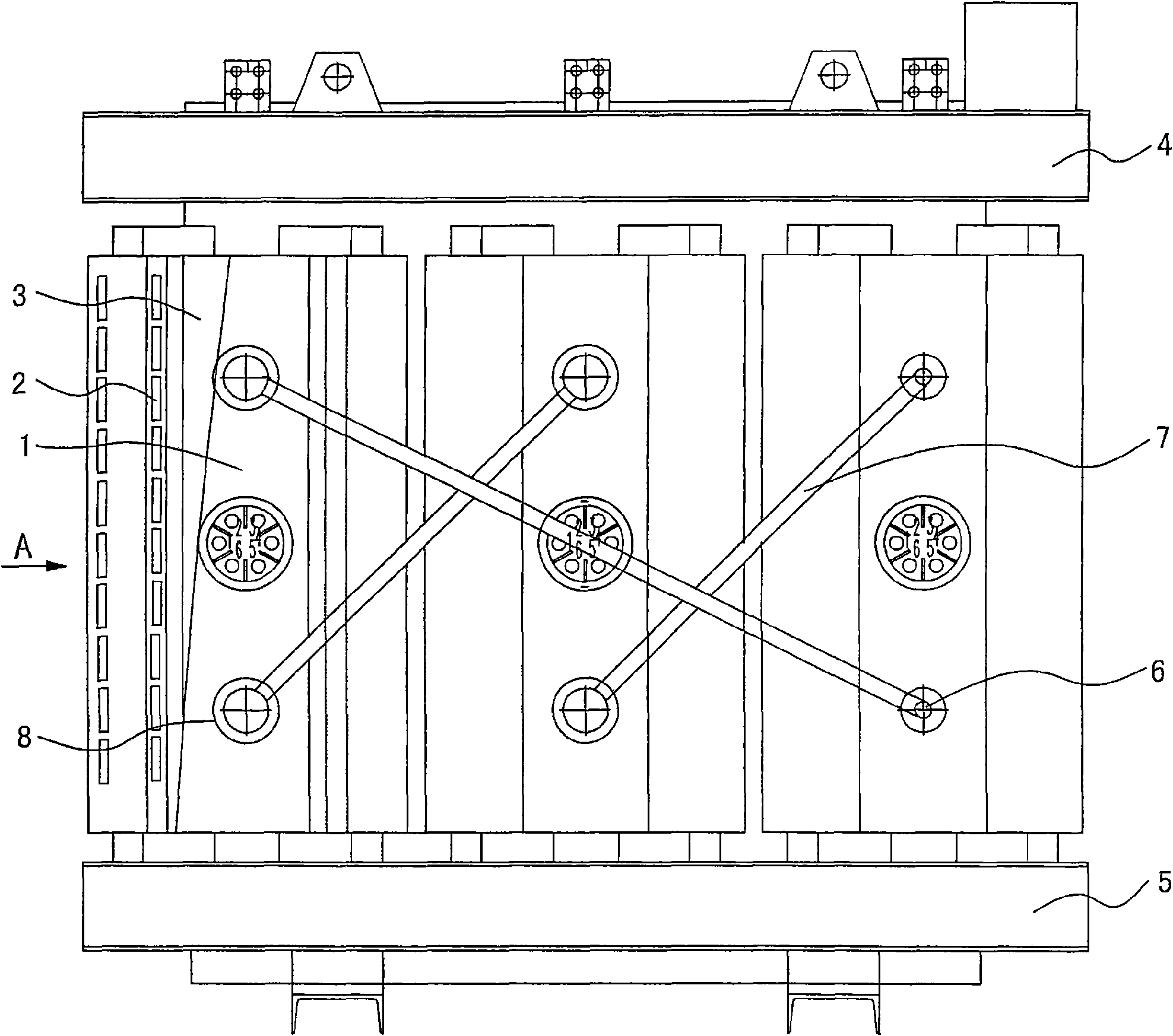

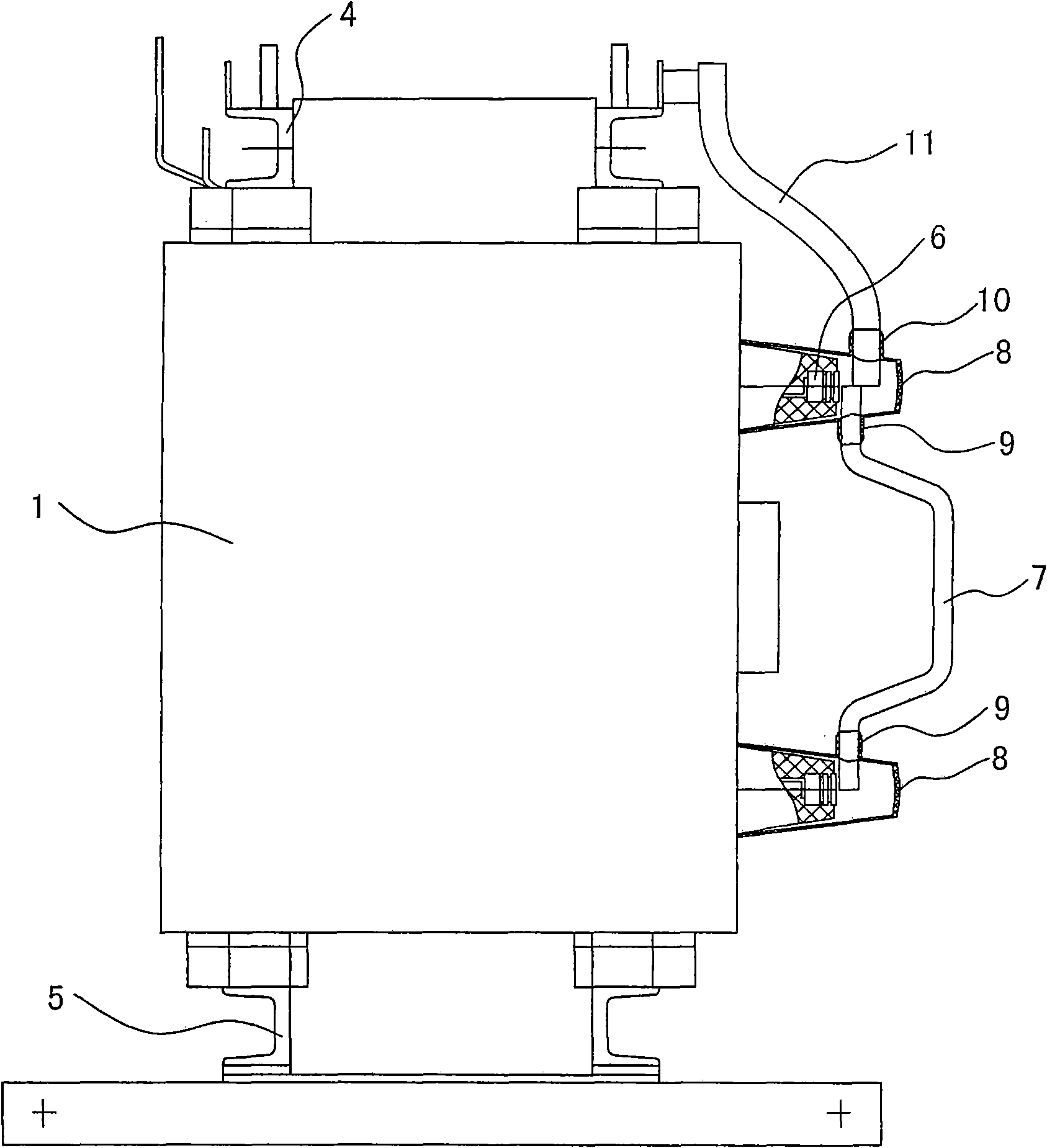

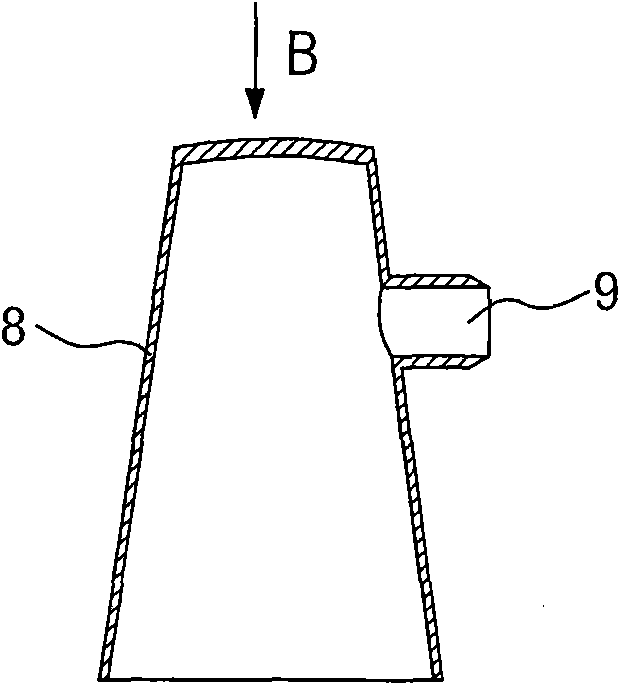

[0013] The invention relates to an insulating device for high-voltage outlet terminals of dry-type transformers, such as Figure 1-Figure 6 As shown, it consists of a high-voltage coil cast body 1, a low-voltage coil cast body 2, an iron core 3 installed inside the low-voltage coil cast body 2, and upper and lower clamps 4 and 5 for fixing the high and low-voltage coil cast bodies. The outer wall of the high-voltage coil casting body 1 is provided with a high-voltage outgoing line terminal 6, which is connected with a lead wire 7, and is characterized in that a closed insulating sheath 8 is installed on the outside of the high-voltage outgoing line terminal 6, and the side wall of the insulating sheath 8 is formed with a lead wire Outlet 9, lead wire outlet 9 is matched with lead wire 7. This solution installs an insulating sheath 8 outside the high-voltage outlet terminal 6. Compared with the existing structure, it eliminates the phenomenon that the outlet terminal of the dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com