A mobile concrete batching plant

A technology of batching equipment and concrete, which is applied to batching batching instruments, batching weighing instruments, clay preparation devices, etc., can solve the problems of extra cost of batching equipment, elevation, and hindering the transportation of batching equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Before the preferred embodiments of the present invention are described in detail, it is to be understood that the phraseology and terminology which have been used herein are for the purpose of description only and are not to be regarded as limiting.

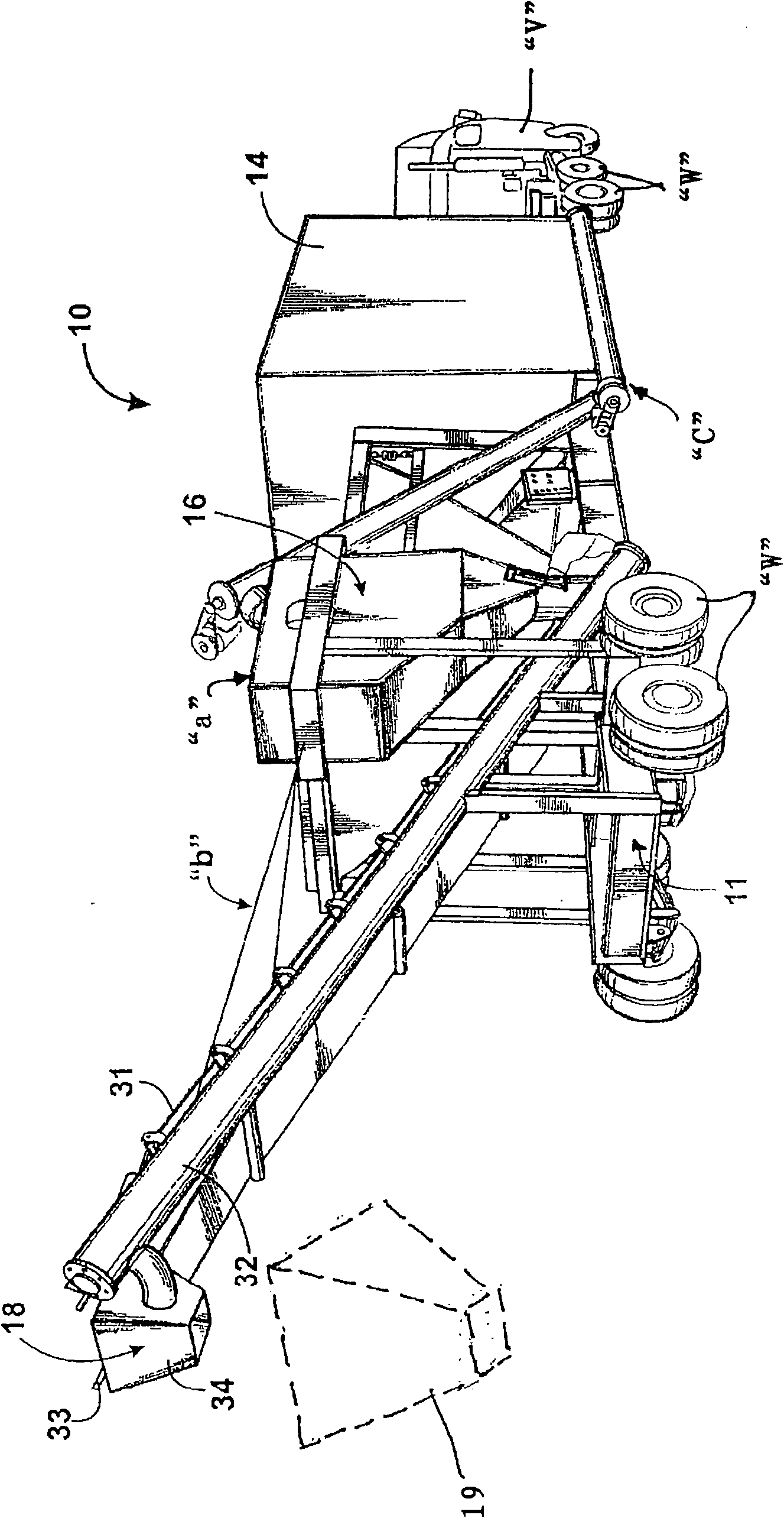

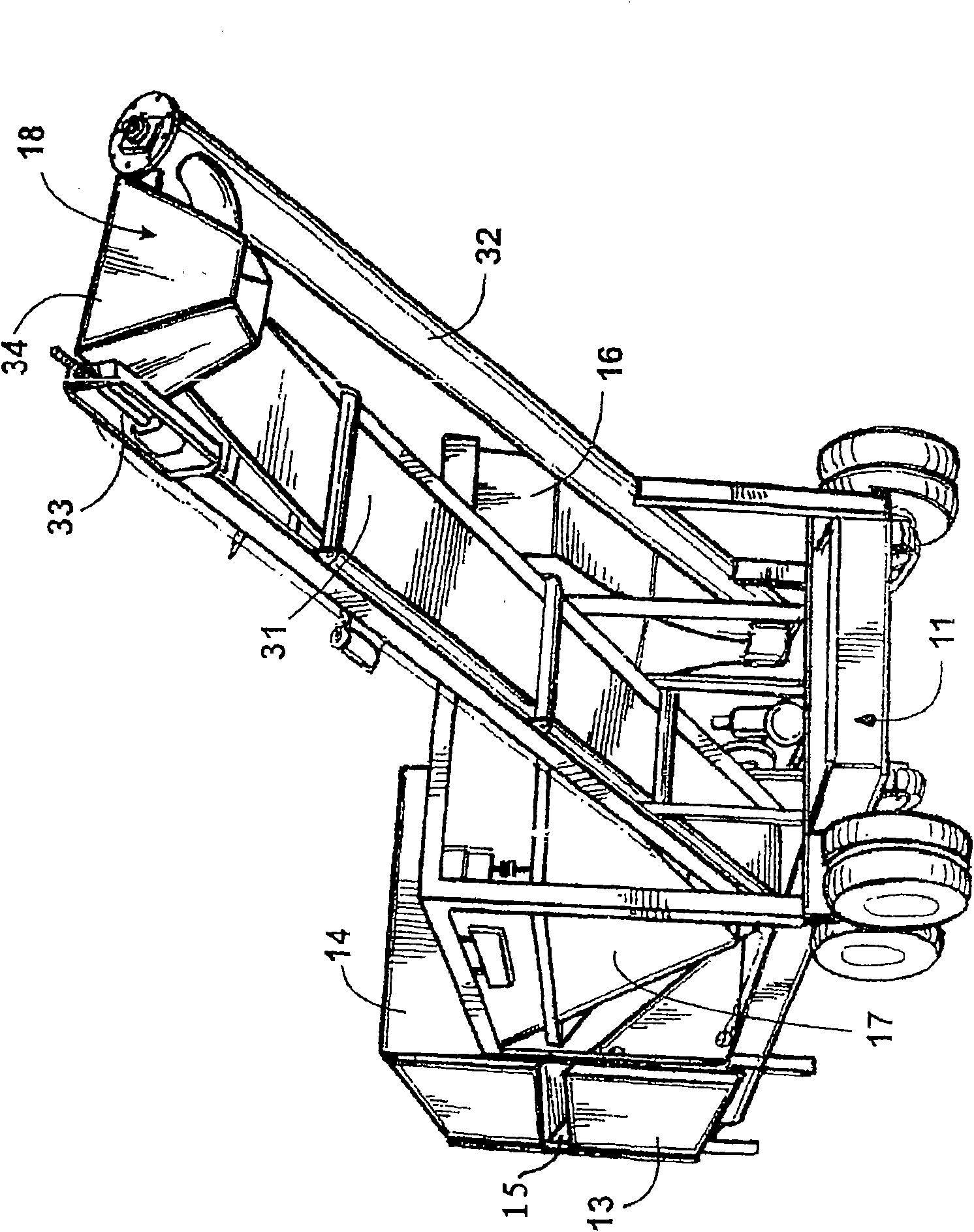

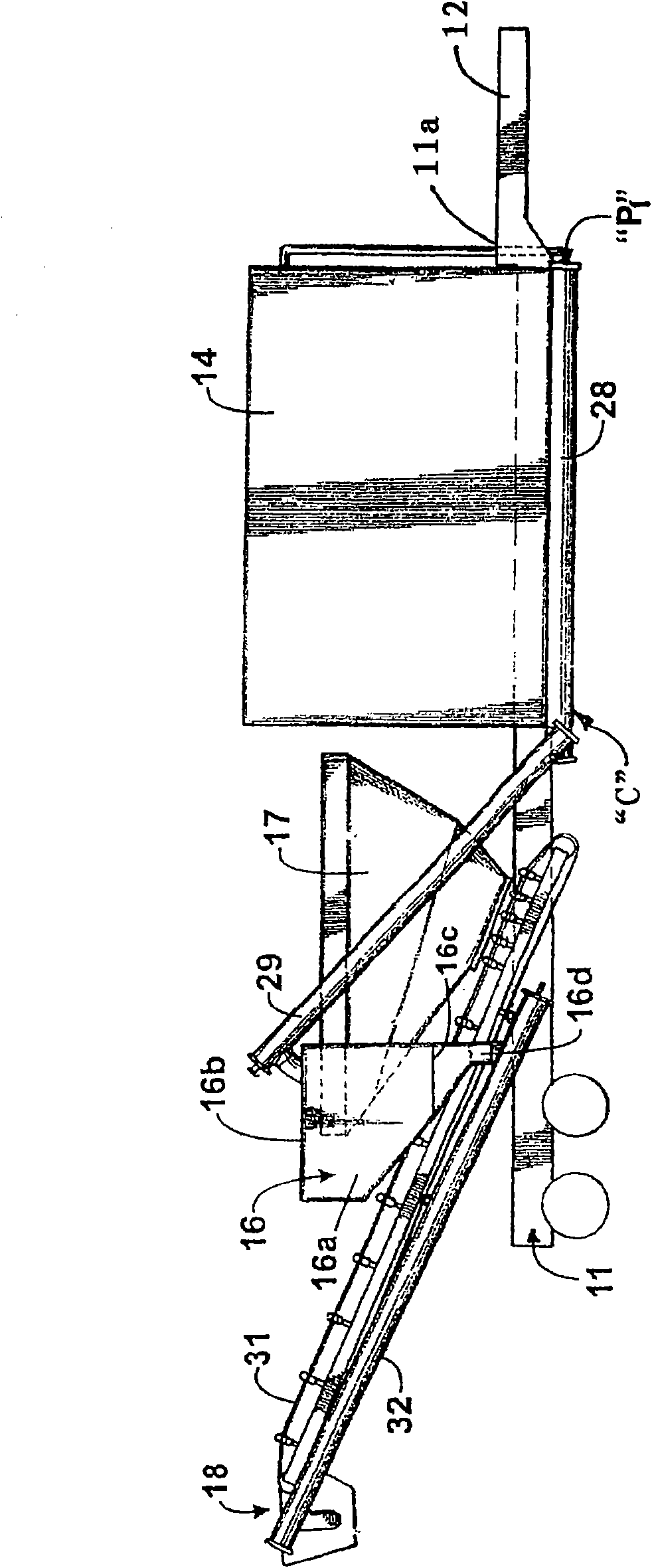

[0035] Referring now to the different views of the drawings, in which like reference numerals indicate steps, parts or elements in the following enabling description, there is shown a mobile concrete batching plant generally designated 10 invention.

[0036] Referring now specifically to the attached Figure 1-5 , the mobile concrete batching plant 10 according to the present invention comprises: a main frame support assembly 11 having a chassis 12 disposed at its rear end portion 11a and detachably connected to the transport device "V", and preferably supported on the main frame The transport wheel W provided at the front of the assembly 11; the water supply tank 13 supported on the lower rear part of the main frame sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com