Powder adhesives for bonding elastomers

A technology of adhesives and elastomers, applied in adhesive types, other rubber adhesives, conjugated diene adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

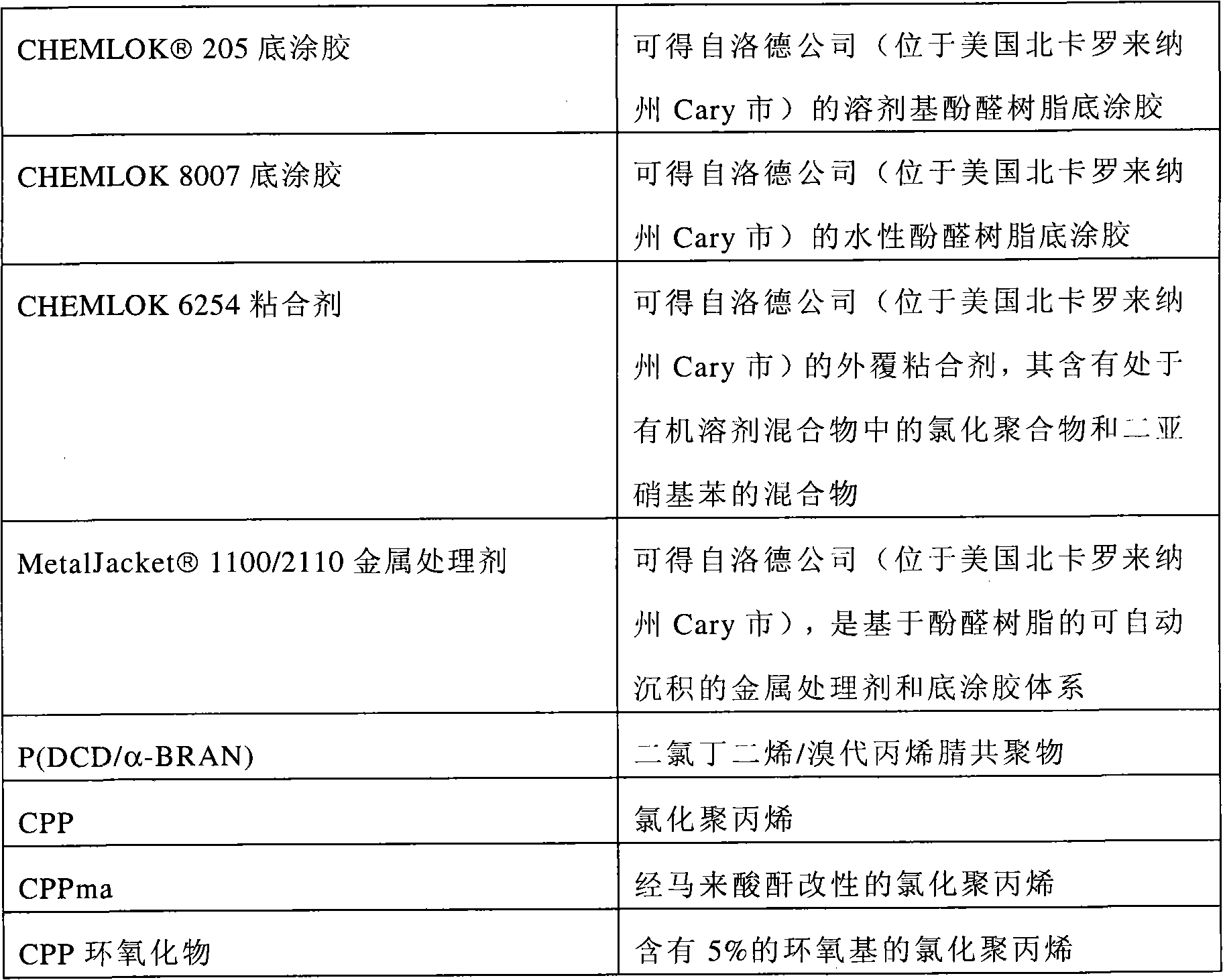

Method used

Image

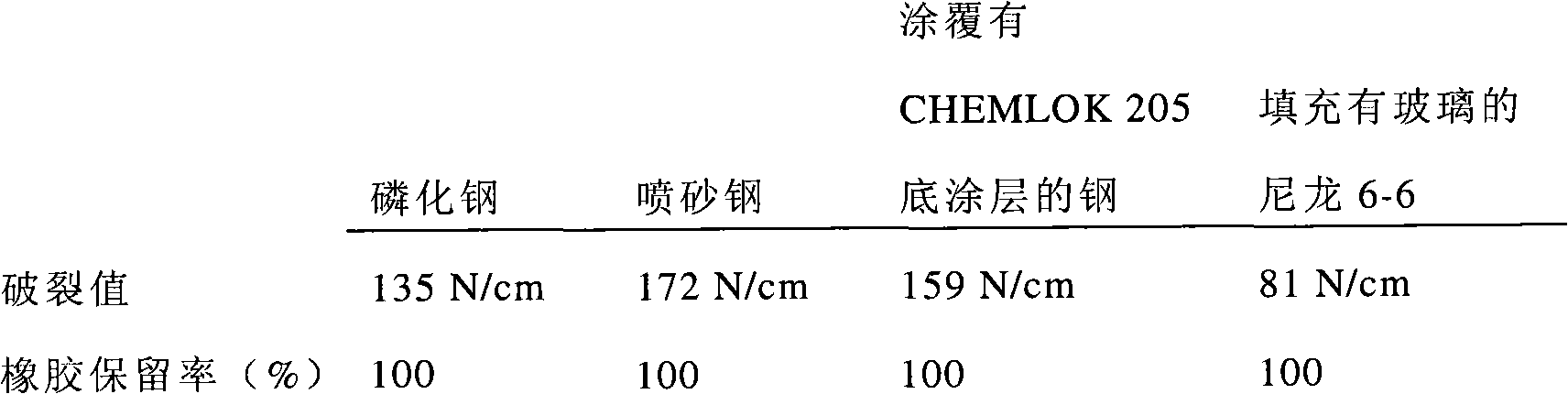

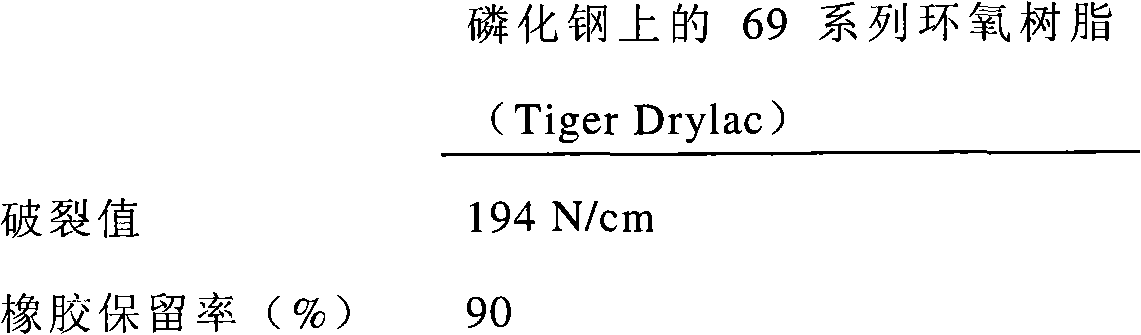

Examples

Embodiment 1

[0042] A 90 / 10 P(DCD / α-BRAN) binder system was sprayed at a film thickness of 25.4 μm on top of the CHEMLOK 205 primer. The rubber was bonded at 171 °C and 13.8 MPa for 14 minutes.

Embodiment 2

[0044] Bromide P(DCD) (bromine content is about 7% by weight) was applied on the CHEMLOK 205 primer layer with a film thickness of 50.8 μm, and bonded in the same manner as in Example 1.

Embodiment 4

[0048] A 90 / 10 P(DCD / α-BRAN) adhesive system with a film thickness of 25.4 μm was applied on MetalJacket 1100 / 2110 metallizer, followed by bonding of natural rubber at 160° C. and 13.8 MPa for 14 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com