An extended drain transistor and a method of manufacturing the same

A transistor and drain technology, applied in the field of extended drain transistors, can solve problems such as the failure of traditional transistor manufacturing processes, and achieve the effects of reducing hot carrier effects, accurate alignment, and saving silicon area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The examples in the figures are schematic. In different figures, similar or identical components are provided with the same reference numerals.

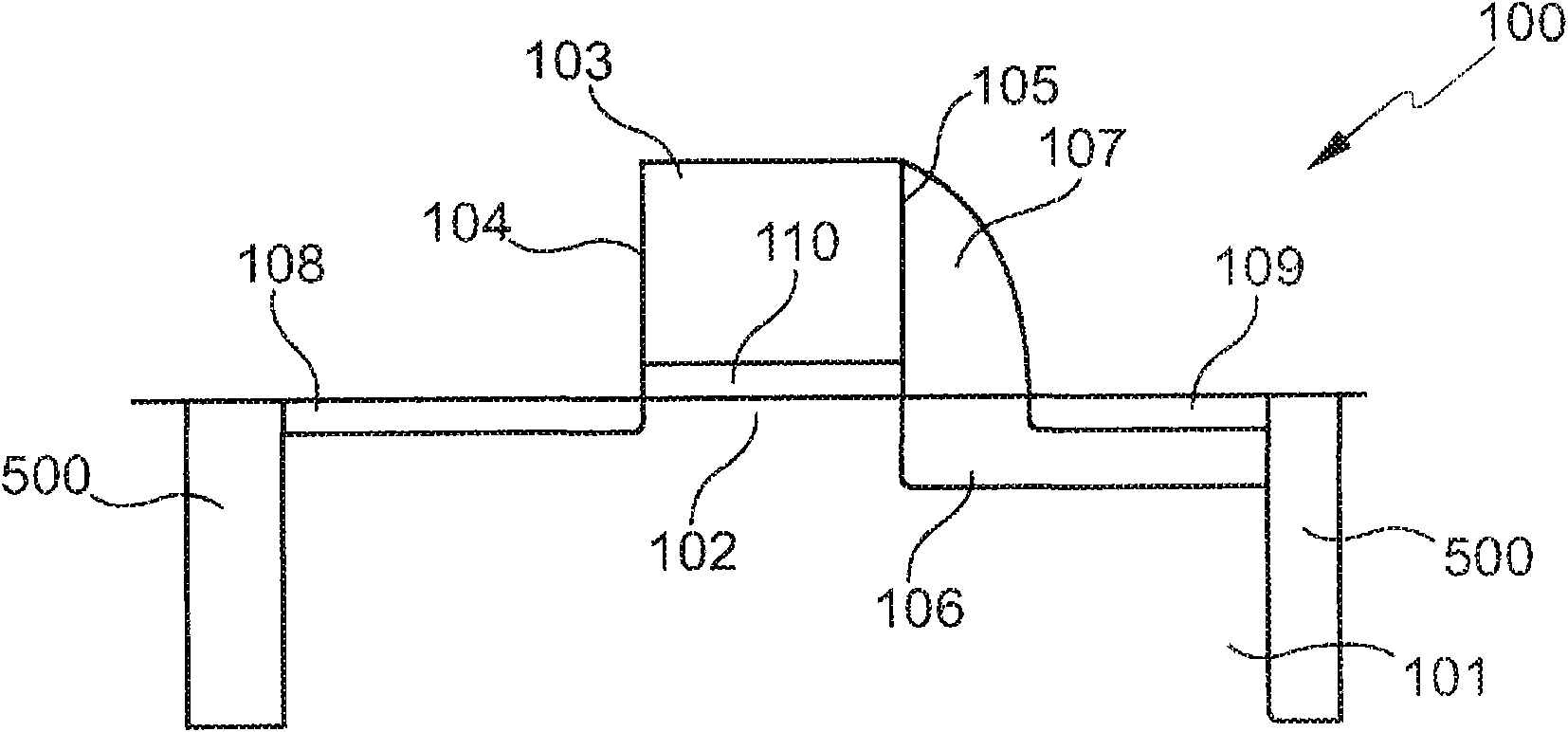

[0062] In the following, refer to figure 1 , the EDMOS transistor 100 according to an exemplary embodiment of the present invention will be described.

[0063] The EDMOS transistor 100 is monolithically integrated in a silicon substrate 101 . The silicon substrate 101 may be essentially free of any dopants, or may be intrinsically doped so that a channel region 102 is formed in its central portion.

[0064] The EDMOS transistor 100 also includes a polysilicon gate 103 formed on the silicon substrate 101 , wherein the gate 103 has a first vertical sidewall 104 and a second vertical sidewall 105 opposite the first sidewall 104 . The EDMOS transistor 100 comprises an extended drain region 106 implanted as a region of low dopant concentration on the surface portion of the silicon substrate 101 directly adjacent to the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com