Machine tool metering parallel

A pad iron and machine tool technology, applied in the directions of weighing, measuring force, supporting machines, etc., can solve problems such as precision reduction, machine tool vibration, machine tool deformation, etc., and achieve the effect of preventing machine tool offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

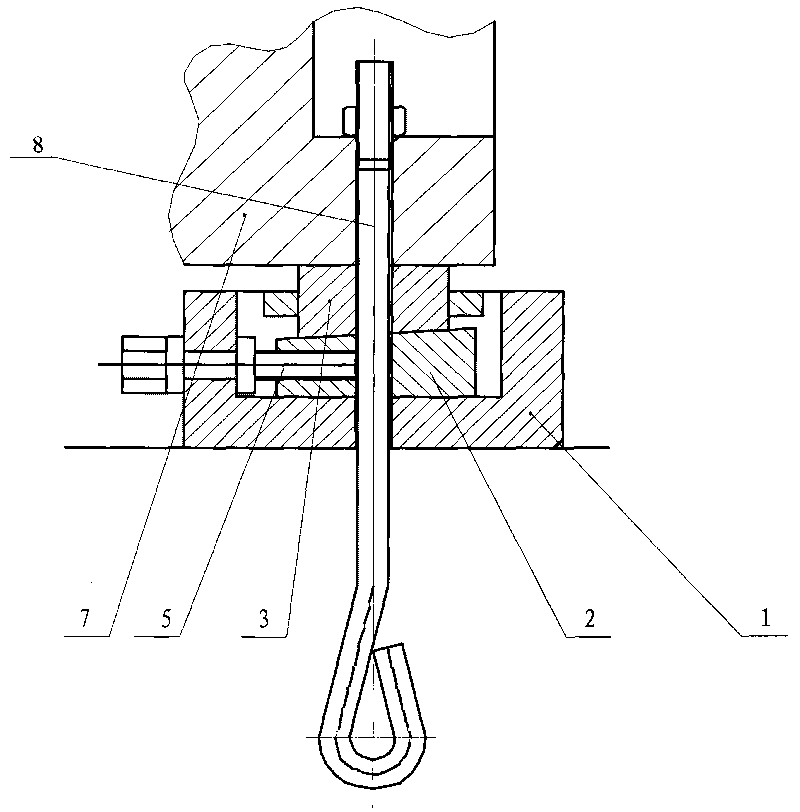

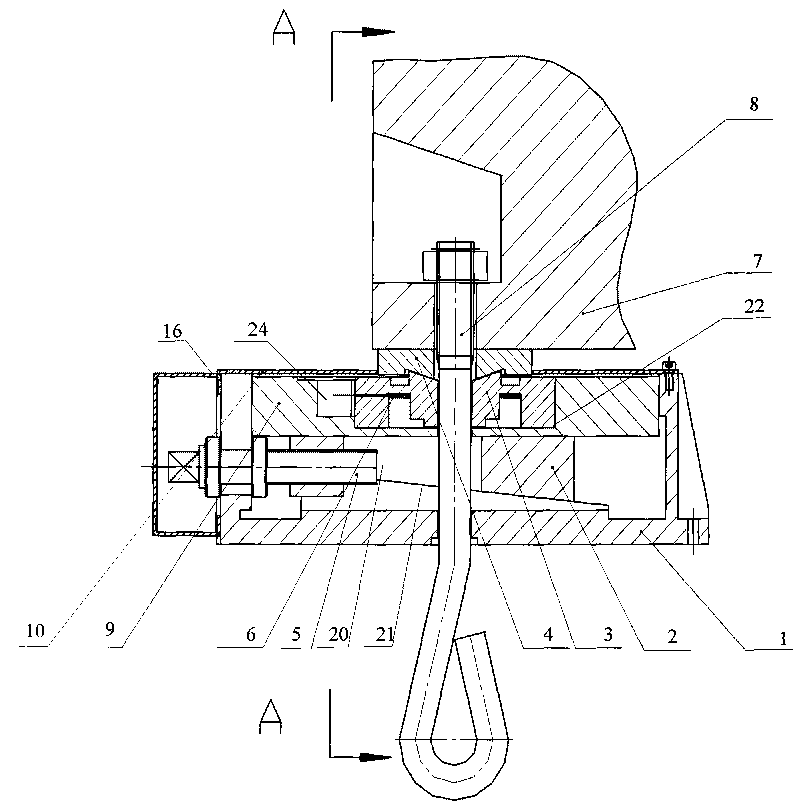

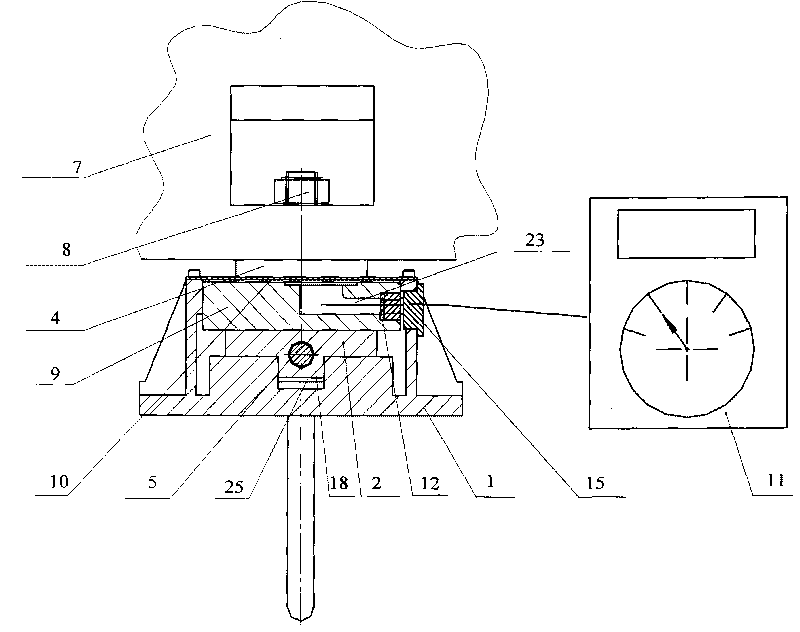

[0021] Attached below figure 2 , 3 , 4, 5, 6 describe an embodiment of the present invention.

[0022] A machine tool metering pad iron, comprising a pad iron base 1, an inclined iron 2, a lower pad 3, an upper pad 4 and an adjusting bolt 5, the outer end of the adjusting bolt 5 is installed on the side wall of the pad iron base 1, and the inner end It is screwed on the screw hole on the side wall of the inclined iron 2. The bottom surface of pad iron seat 1 inner cavity is shaped on inclined plane 21, is shaped on groove 25 on inclined plane 21, and the upper end face of inclined iron 2 is the plane lower end face is inclined plane, and is shaped on boss I 18 on its inclined plane, inclined iron 2 Located on the inclined plane 21, and the boss I 18 is located in the groove 25; the pad seat 9 is placed on the upper end face of the inclined iron 2, the lower pad iron 3 is placed in the cavity 22 of the pad seat 9, and the upper pad 4 Located on the lower block 3, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com