Quick locking and width adjusting device for supernatant cancelled plates and working method thereof

A format adjustment and super-clearing technology, which is applied in metal processing and other fields, can solve the problems of time occupation and complicated operation, and achieve the effect of simple structure and shortened adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

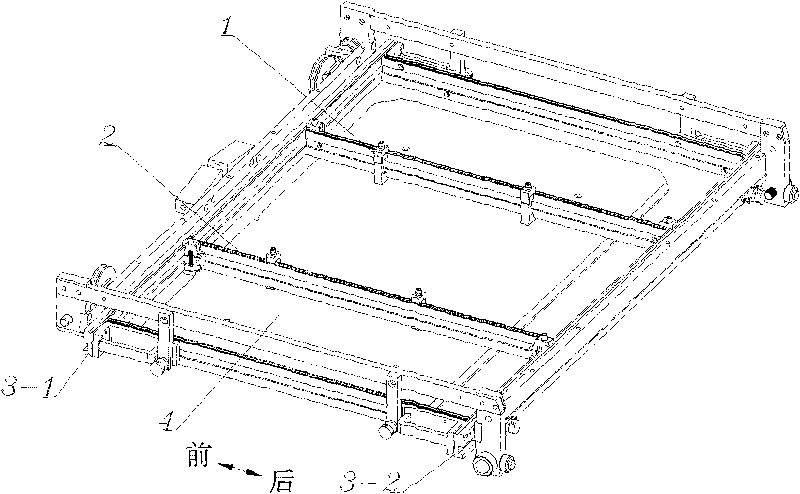

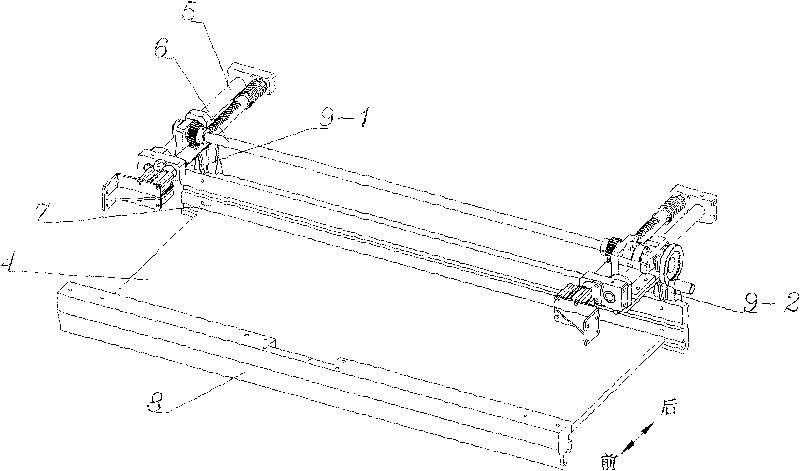

[0021] Embodiment: a kind of fast locking and width adjustment device of cleaning waste plate (see figure 2 ), including the upper cleaning waste plate 4, is characterized in that it is composed of a width adjustment mechanism 6, two symmetrical cylinder-type locking mechanisms 5, a clamping guide rail 7 and a fixed guide rail 8, wherein the said width adjustment mechanism 6 and the two A symmetrical cylinder-type locking mechanism 5 is engaged with the gear and the rack respectively; the clamping guide rail 7 is fixedly connected with the width adjustment mechanism 6 according to the connection block I9-1 and the connection block II9-2; the fixed guide rail 8 is fixed on the waste stripping die-cutting machine; said upper stripping waste plate 4 is installed in the groove of clamping guide rail 7 and fixed guide rail 8.

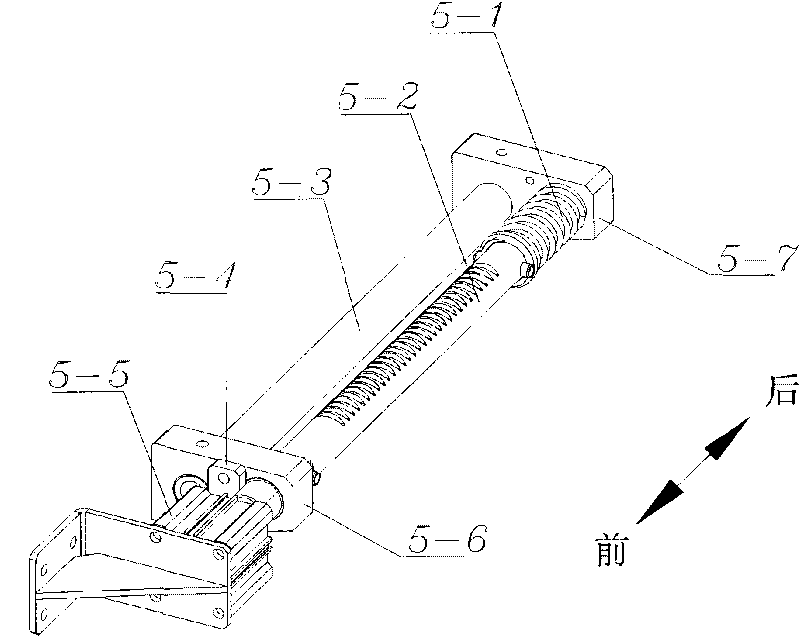

[0022] The above-mentioned two symmetrical cylinder-type locking mechanisms 5 (see image 3 ) are all made of spring 5-1, rack shaft 5-2, guide shaft 5-3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com