Novel stiffening structure of super-large box-shaped compression member of steel bridge and construction method thereof

A construction method and pressure bar technology, applied in bridge parts, bridges, bridge construction and other directions, can solve the problems of not meeting the stress requirements of the large vertical bars of the Dongjiang Bridge, the compression stability reduction coefficient is small, and the secondary stress of nodes increases. , to achieve the effect of adding bridge landscape effect, improving operation efficiency and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

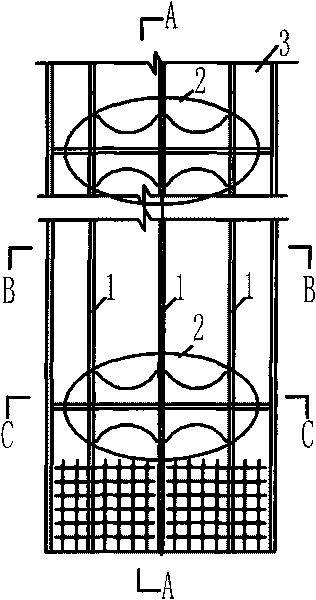

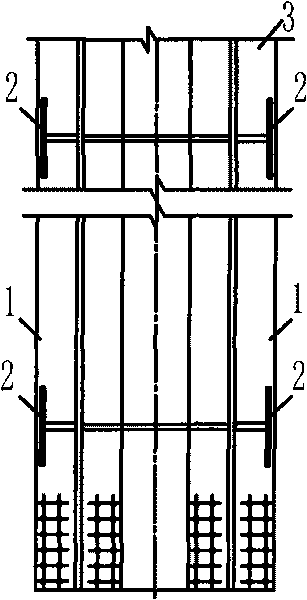

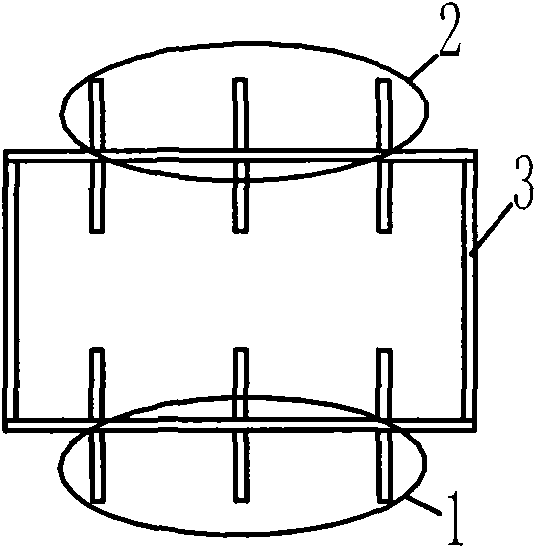

[0025] refer to Figure 1 to Figure 4 , the new stiffening structure of the steel bridge box-shaped extra-large pressure member is to add a stiffener 1 outside the box-shaped section 3 of the large member, and the stiffener is outsourced with a landscape decoration structure 2.

[0026] refer to Figure 5 , the extra-large pressure member 4 of the present invention is applied on the Guangdong Dongjiang double-layer highway bridge 5, and the bridge has been successfully closed at present, and will be opened for operation within the year.

[0027] Concrete construction steps of the present invention are as follows:

[0028] 1) Segmentation of new super-large pressure rods: Divide new super-large pressure rods into segments according to possible lifting equipment and transportation capacity.

[0029] 2) Segment production:

[0030] ① Plate unit production: After the steel plate passes the re-inspection of the factory, the pretreated steel plate is blanked and edge processed acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com