Column joint structure of building and connection method thereof

A technology of column joints and buildings, which is applied in the direction of building structure and construction, can solve the problems of long waiting period, difficult operation, difficult construction, etc., and achieve fast installation, convenient precision control, and easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

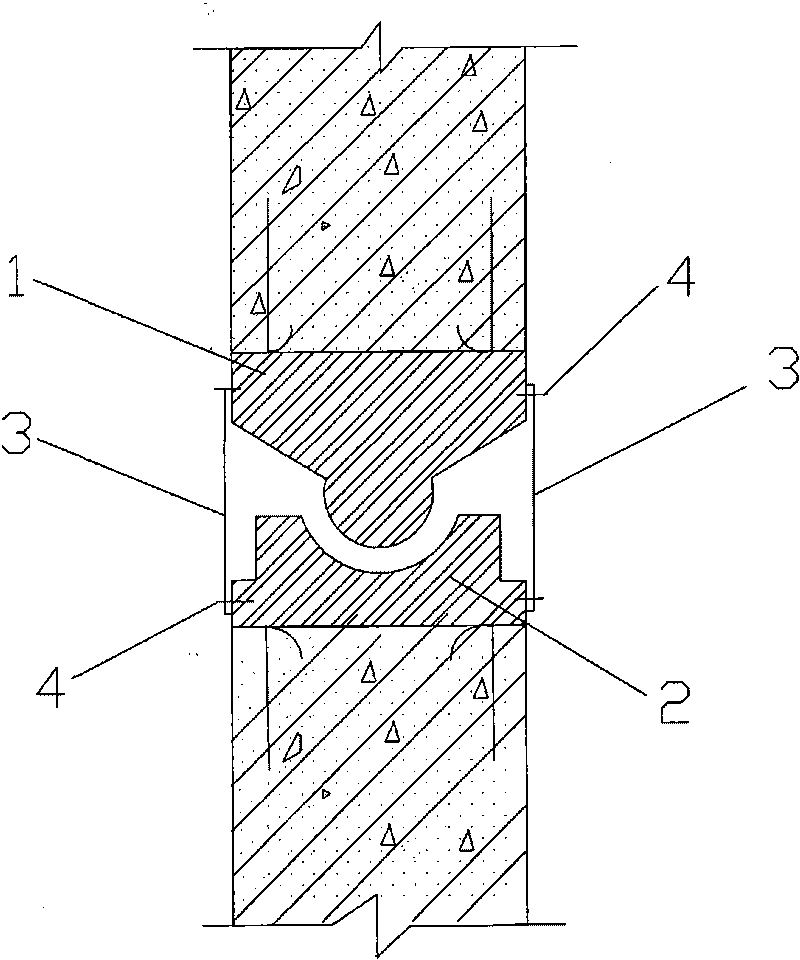

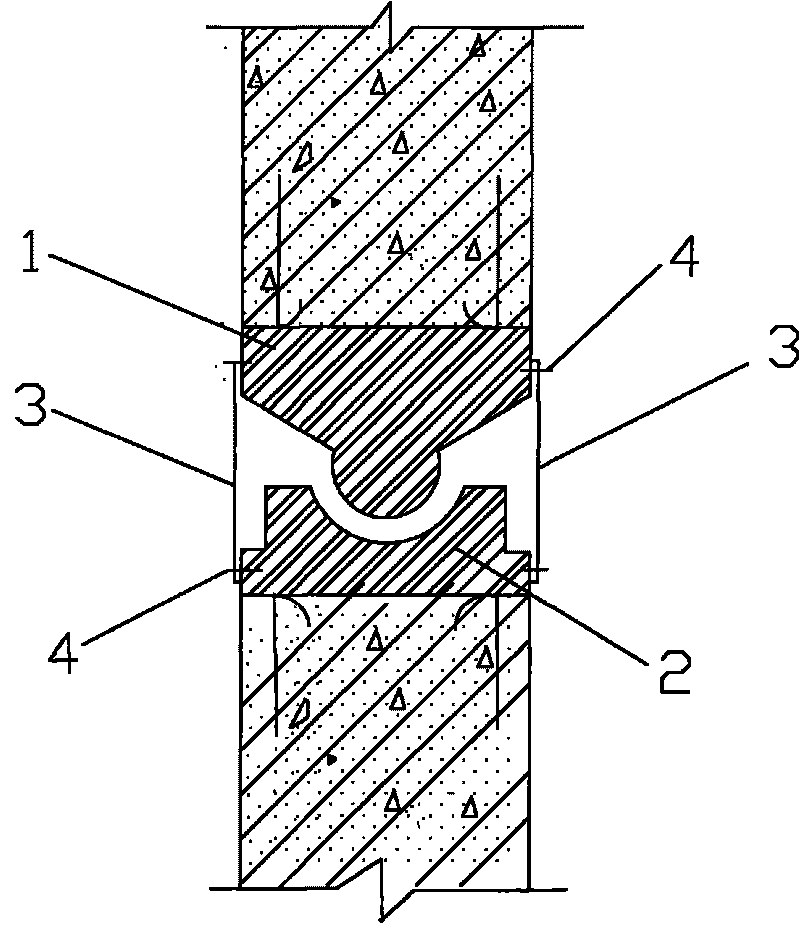

[0028] see figure 1 , in this embodiment, between the upper column and the lower column, the interconnected column joints adopt a concave-convex structural form, and the concave-convex structural form is to set a concave spherical surface at the center of the column top surface of the lower column, and the relative position The column bottom surface of the upper column is set as a convex spherical surface, and the concave spherical surface and the convex spherical surface form a joint that can rotate relative to each other. The outer peripheries of the upper column and the lower column are evenly distributed. connecting plate.

[0029] In specific implementation, the corresponding structural settings also include:

[0030] Both the concave spherical surface and the convex spherical surface are made of cast steel or high-strength materials. They are respectively fixed on the top of the lower column and the bottom of the upper column in a pre-embedded manner. It is required to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com