Integrated self-insulating light wallboard

A light-weight wallboard and self-insulation technology, which is applied in the field of building wall materials, can solve problems such as large-area shedding, uneven thickness of the outer layer, water ingress, etc., to reduce bulk density, excellent thermal insulation performance, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the examples. It should be understood that these examples are only for the purpose of illustration, and in no way limit the protection scope of the present invention.

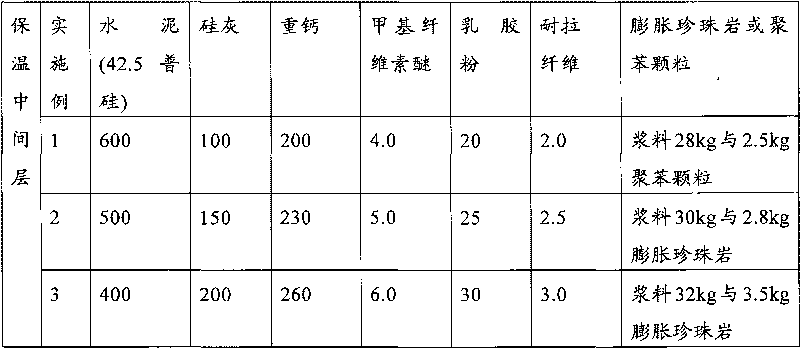

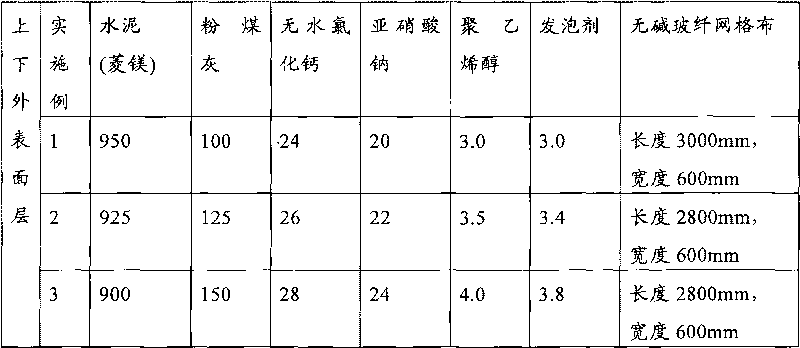

[0031] The integrated self-insulating lightweight wallboard is expressed by the ratio of each raw material and text in Table 1 (weight unit: kg)

[0032] Table 1

[0033]

[0034]

[0035] The preparation method of described whipping agent is as follows:

[0036] A. Part B: 10-25 parts of calcium chloride, 12-15 parts of sodium nitrite, 8-10 parts of sodium sulfate, 0.2-0.5 parts of triethanolamine, 54.7-64.5 parts of water; heat the water to 30-50°C Finally, add the above components at the same time, stir evenly and pack into barrels for later use;

[0037] B. Component A: Take 53.5-55.8 parts of water, heat 30% of the water at 70-80°C and dilute the polyvinyl alcohol for use; put the remaining water into a heat container,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap