Self-condensing gas-water separating device of water-ring vacuum pump set

A technology of gas-water separation device and water-ring vacuum pump, which is applied to pump components, mechanical equipment, variable-capacity pump components, etc., can solve the problems affecting the working performance of vacuum pumps, poor pumping efficiency of vacuum pumps, and no cooling effect. Long-term stable operation, improve cooling effect, save tap water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

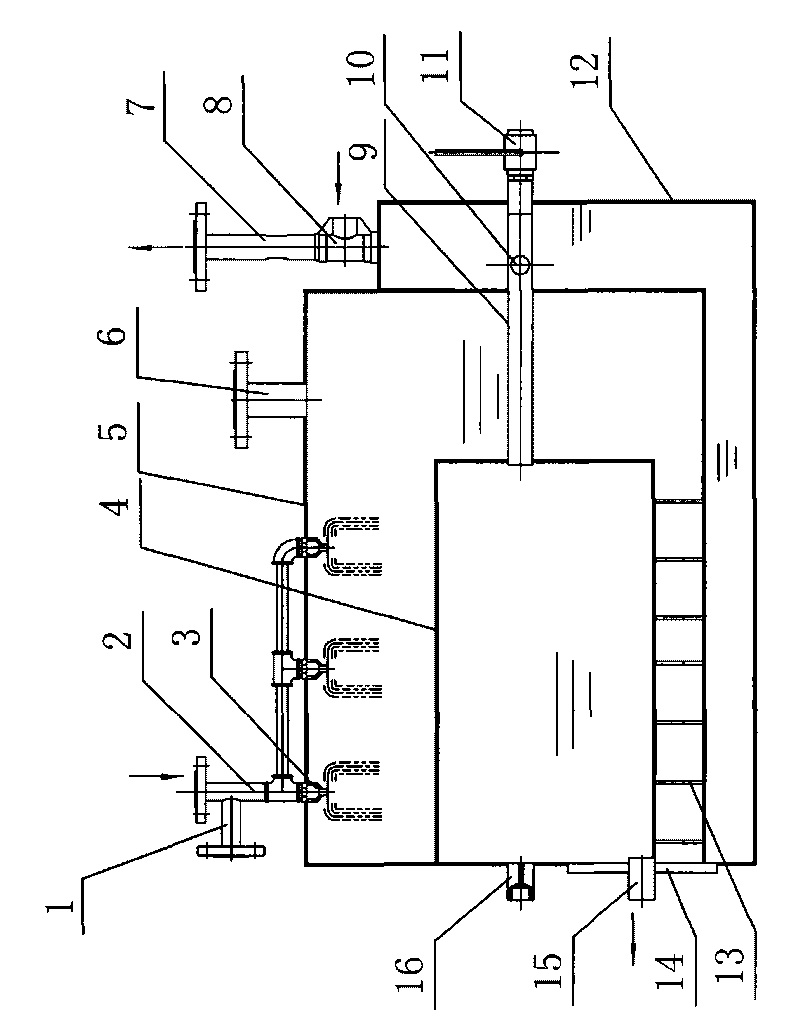

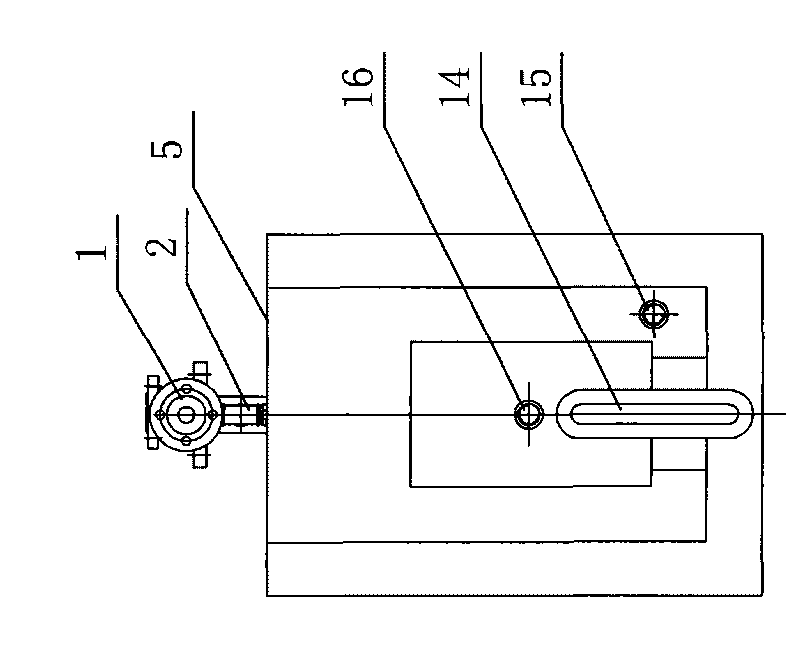

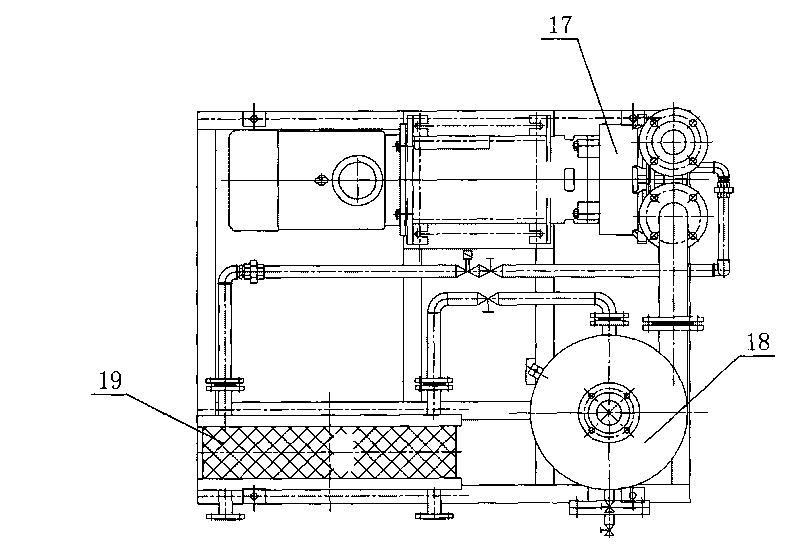

[0022] Such as figure 1 , figure 2 As shown, the self-condensing gas-water separation device of the water ring vacuum pump unit according to the present invention is provided with an intermediate water tank 5, the interior of the intermediate water tank 5 is provided with an inner condensation tank 4, the middle water tank 5 is outsourced with an outer condensation tank 12, and the middle water tank 5 The top is provided with an exhaust port 6 and the pump working fluid return port 2, the bottom is provided with a pump working fluid supply port 15, and the top of the middle water tank 5 is provided with a spray head 3, several of which can be arranged side by side. The spray head 3 is connected to the pump working On the liquid return port 2, the working fluid return port 2 is connected to the working liquid replenishment port 1, and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com