Internal linkage type reducing valve

A pressure reducing valve and low-pressure chamber technology, applied in the field of interlocking pressure reducing valves, can solve the problems affecting the pressure reducing performance of the pressure reducing valve, the structure of the pressure reducing valve is complicated, and the performance is not stable enough, so as to save material costs and have a simple structure , The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

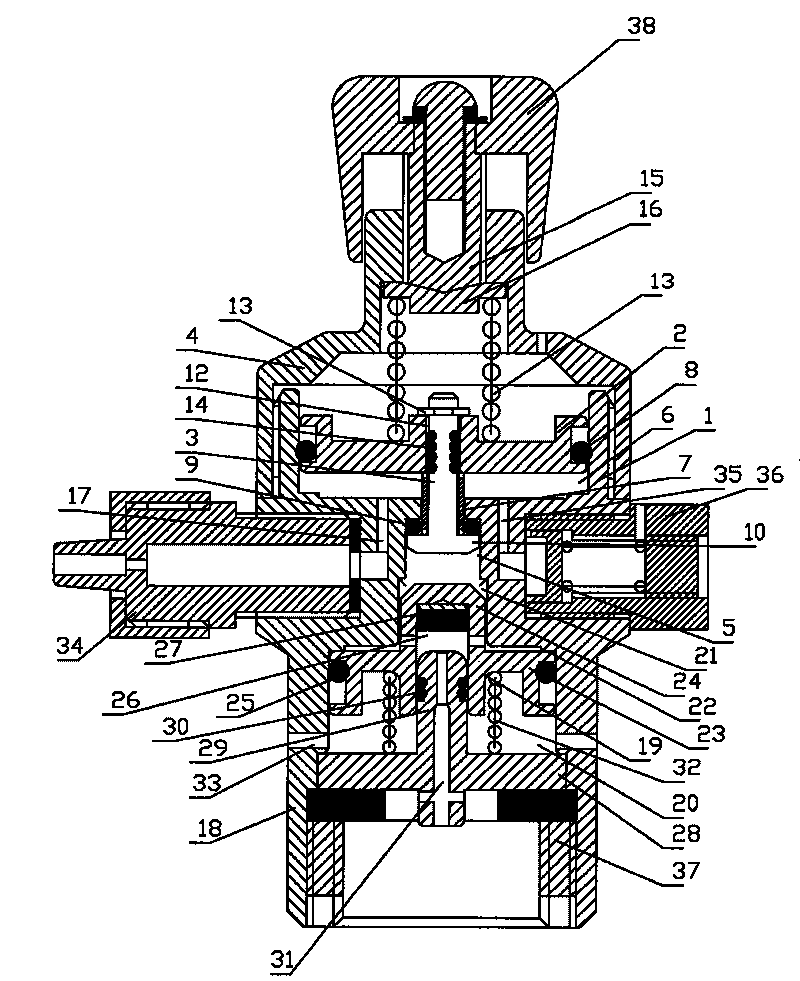

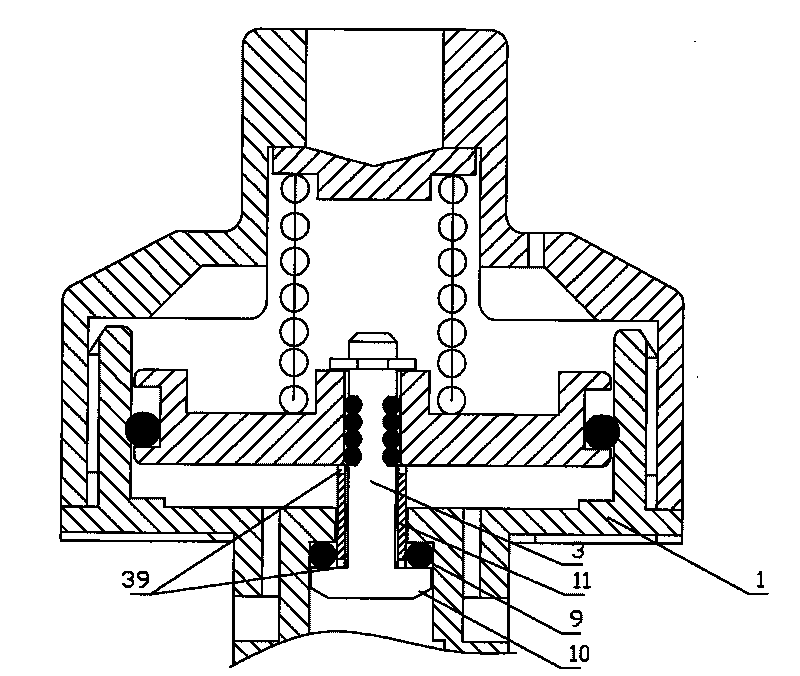

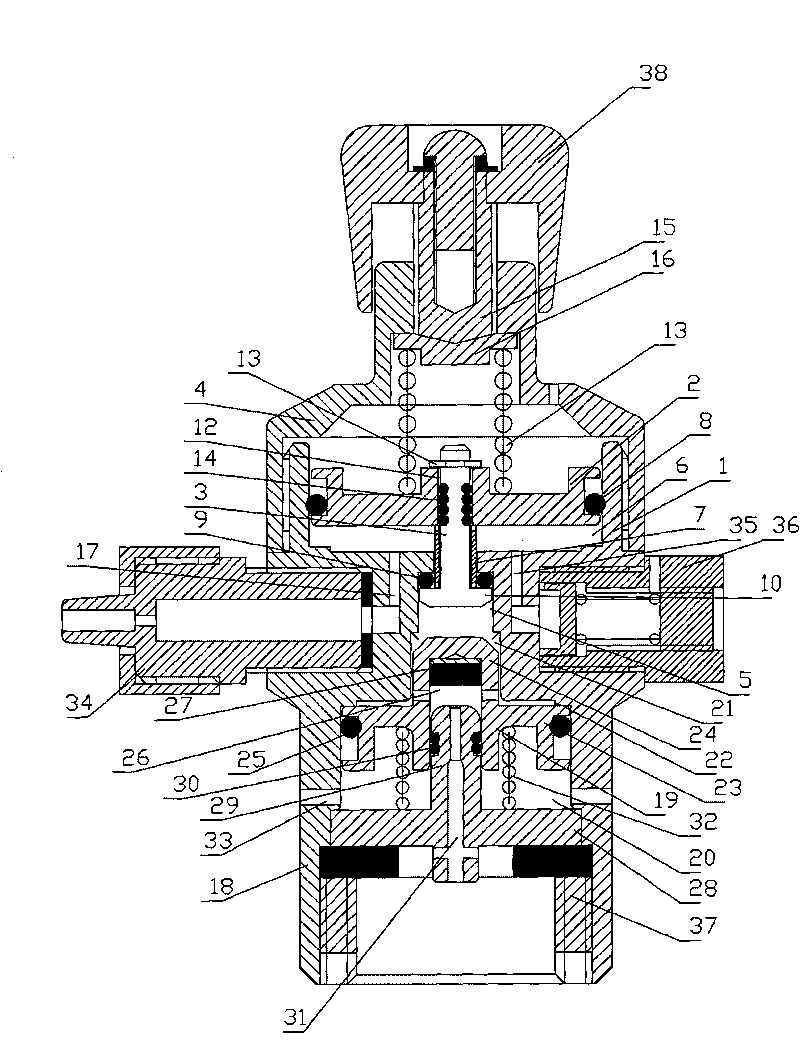

[0030] Example: such as figure 1 , figure 2 As shown, the internal linkage pressure reducing valve includes a main body 1, a piston 2, an intake switch shaft 3, a valve cover 4, a high pressure chamber 5, a low pressure chamber 6, and a pre-stage pressure reducing mechanism. The cross-sectional area of the low pressure chamber 6 is larger than that of the high pressure chamber. The chamber 5 has a large cross-sectional area, and the low-pressure chamber 6 and the high-pressure chamber 5 are connected through the channel 7; Located in the high-pressure chamber 5, the other end passes through the channel 7 and enters the low-pressure chamber 6 to connect with the piston 2; the end of the intake switch shaft 3 located in the high-pressure chamber 5 is provided with an intake seal ring 9, and the intake switch shaft 3 is sealed by the intake air. The end face of the ring 9 and the channel 7 located in the low-pressure chamber 6 are dynamically sealed.

[0031] Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com