Device for measuring elevation of bearing of turbo generator set

A turbo-generator and elevation measurement technology, which is applied in the direction of measuring devices, electric devices, and electromagnetic means, can solve the problems of time-consuming installation and debugging of eddy current displacement sensors, the inability to adjust the height of the measuring bracket, and the easy damage of the measuring bracket. Achieve the effect of simple and reliable structure, reduce measurement error and improve measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

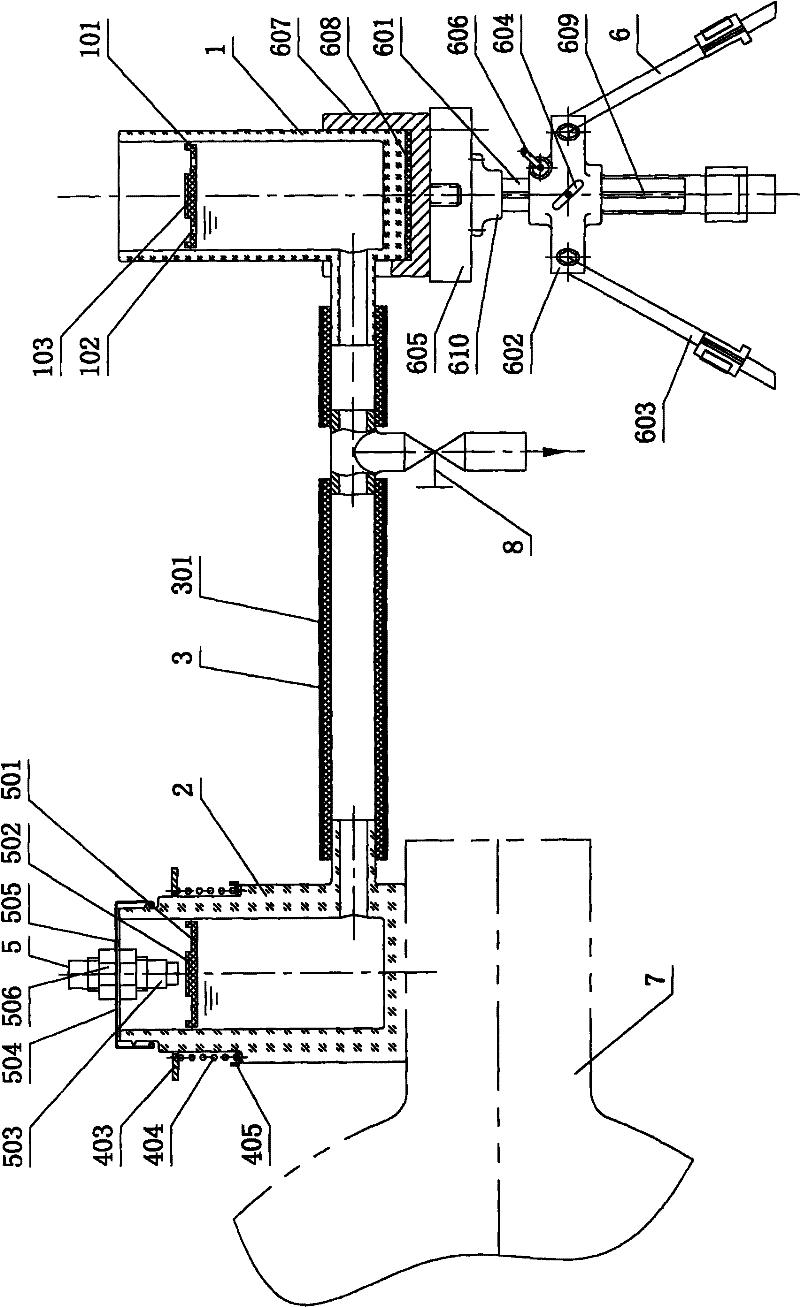

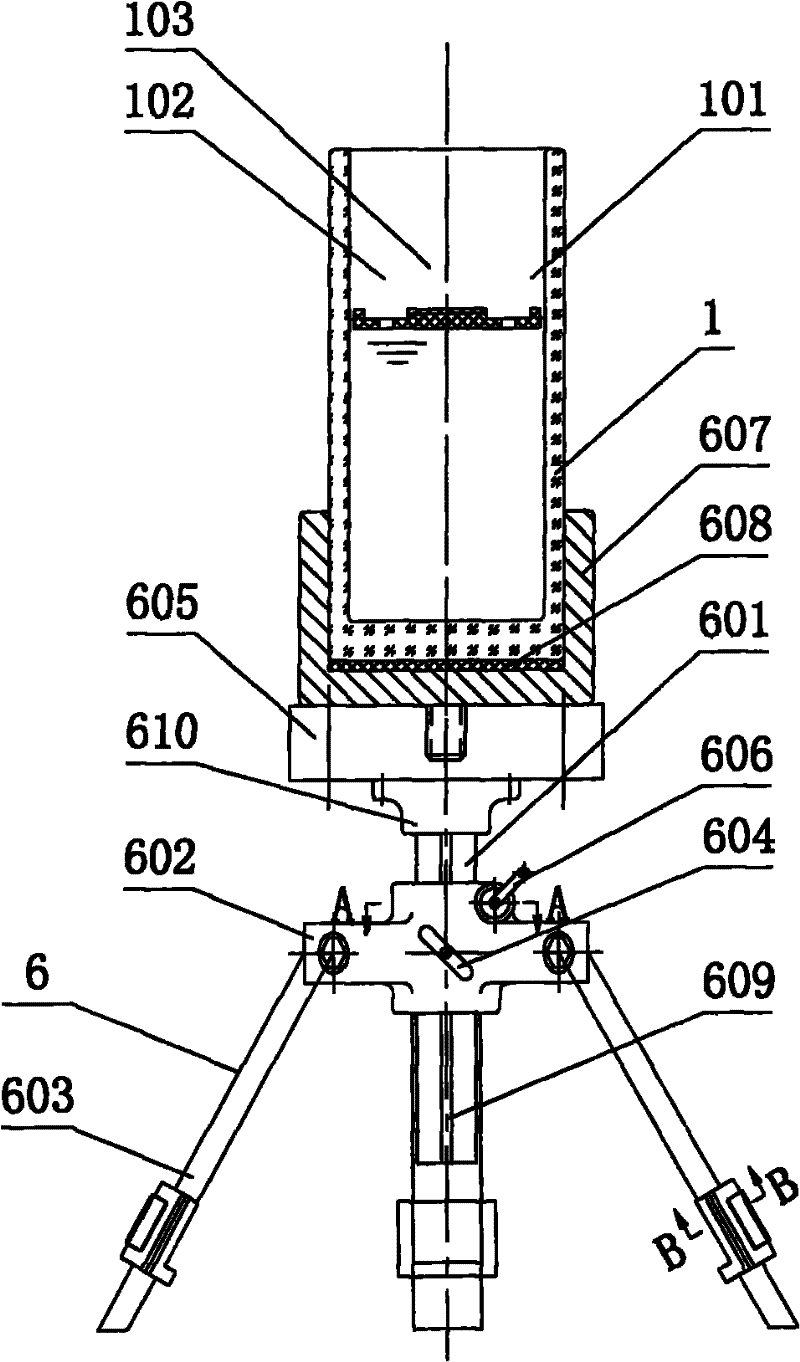

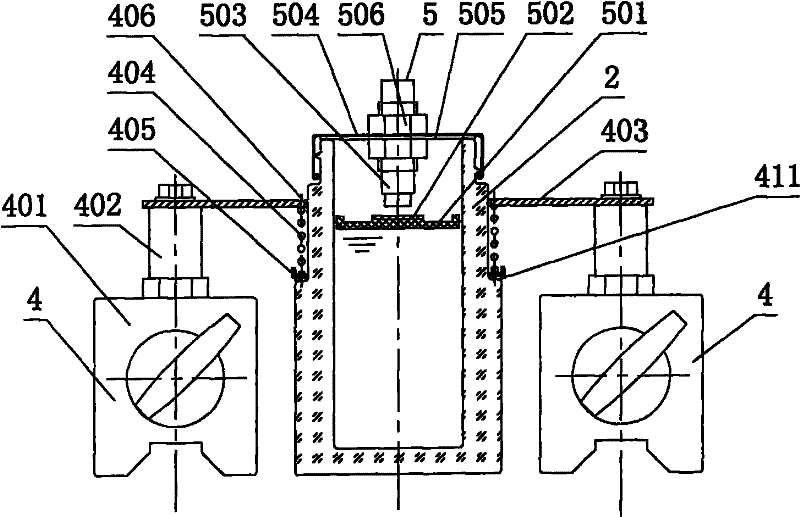

[0058] Embodiment 1: as Figure 1 to Figure 4 As shown, a turbine generator bearing elevation measuring device includes a reference cup 1, a measuring cup 2 and a connecting hose 3. The reference cup 1 and the measuring cup 2 are filled with liquid, and the two are connected through the connecting hose 3. The measuring cup Both sides of the measuring cup 2 are provided with a measuring cup fixing device 4, and the bottom of the reference cup 1 is provided with a height-adjustable reference cup supporting device 6, and the mouth of the reference cup 1 or measuring cup 2 is equipped with a device that can detect the change of the liquid level in the cup. Measuring device 5. In this embodiment, the measuring device 5 is installed at the mouth of the measuring cup 2, and its measuring range is -2000 μm~+2000 μm. The invention utilizes the principle of the connecting device, can measure the change of the bearing elevation of the steam turbine generator set, and analyze the relation...

Embodiment 2

[0068] Embodiment 2: This embodiment is basically the same as Embodiment 1, the only difference is that the structure of the measuring cup fixing device 4 in this embodiment is different, such as Figure 5 and Image 6 As shown, in the measuring cup fixing device 4 of this embodiment, the magnetic adsorption device 401 adopts a self-made magnetic base 407, and a permanent magnet bar 408, two arc-shaped soft irons 409 and two brass blocks are installed in the magnetic base 407 410, two pieces of arc-shaped soft iron 409 and two pieces of brass blocks 410 form a ring and are arranged alternately. In the ring shape, rotating the permanent magnet bar 408 can control the on-off of the magnetic field. In this embodiment, the pressing plate 403 and the magnetic base 407 are integrally formed, and the structure is simpler.

Embodiment 3

[0069] Embodiment 3: This embodiment is basically the same as Embodiment 1, and the only difference is that the structure of the measuring cup fixing device 4 in this embodiment is different, such as Figure 7 and Figure 8 As shown, in the measuring cup fixing device 4 of this embodiment, the magnetic adsorption device 401 is made of a permanent magnet, and no magnetic field on-off control switch is provided. The pressure plate 403 and the magnetic adsorption device 401 are integrally formed, and the structure is simpler and the manufacturing cost is lower. Low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com