Large plate installation mechanical arm

A technology of manipulators and plates, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high labor intensity, large size, poor safety, etc., and achieve the effect of simple structural design, less decoupling calculations, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment and accompanying drawing, technical solution of the present invention is described in detail as follows:

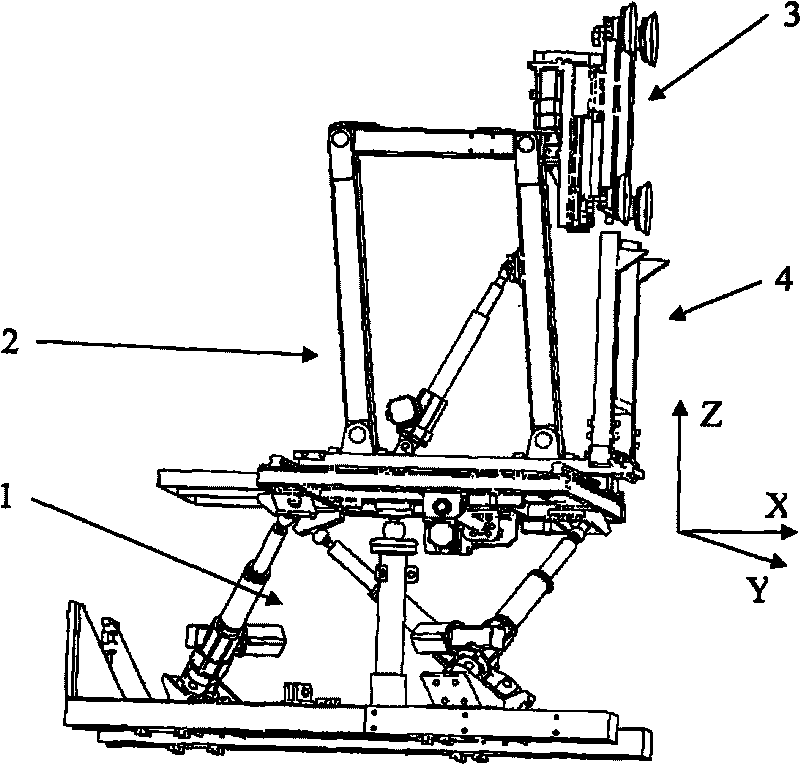

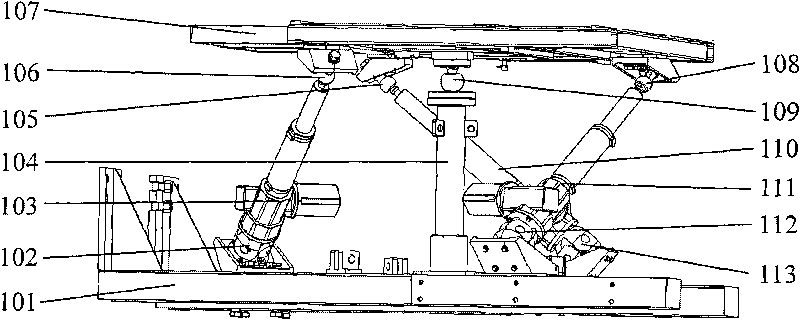

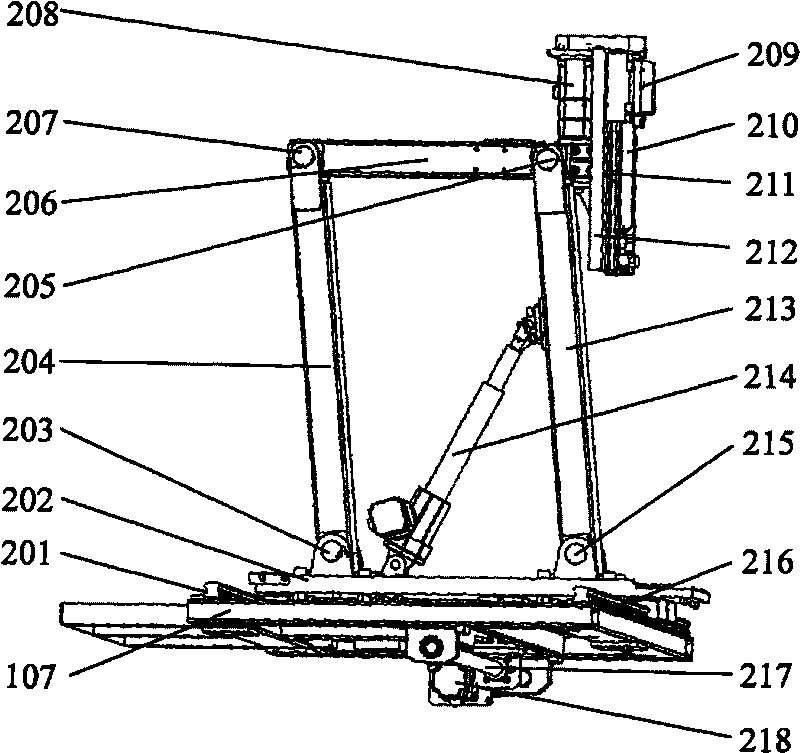

[0014] The large plate installation manipulator designed by the present invention (abbreviation manipulator, see Figure 1-5 ) is based on the requirements of the dry-hanging installation process of large-scale panels, following the modular design idea of the robot structure, and designed according to the workflow of panel installation. The manipulator designed in the present invention adopts a six-degree-of-freedom series-parallel hybrid mechanism, and the main body motion mechanism is mainly composed of a three-degree-of-freedom parallel rotating platform module 1, a three-degree-of-freedom serial moving module 2 installed above the three-degree-of-freedom parallel rotating platform module 1, and The three-degree-of-freedom series mobile module 2 is composed of an end effector module 3 connected.

[0015] The three-degree-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com