Automatic mechanical running-preventing mine car

A mechanical and mine car technology, which is applied to mine cars, transport passenger cars, railway car body parts, etc., can solve problems such as short service life, inability to block or brake cars, and difficulty in braking wire ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

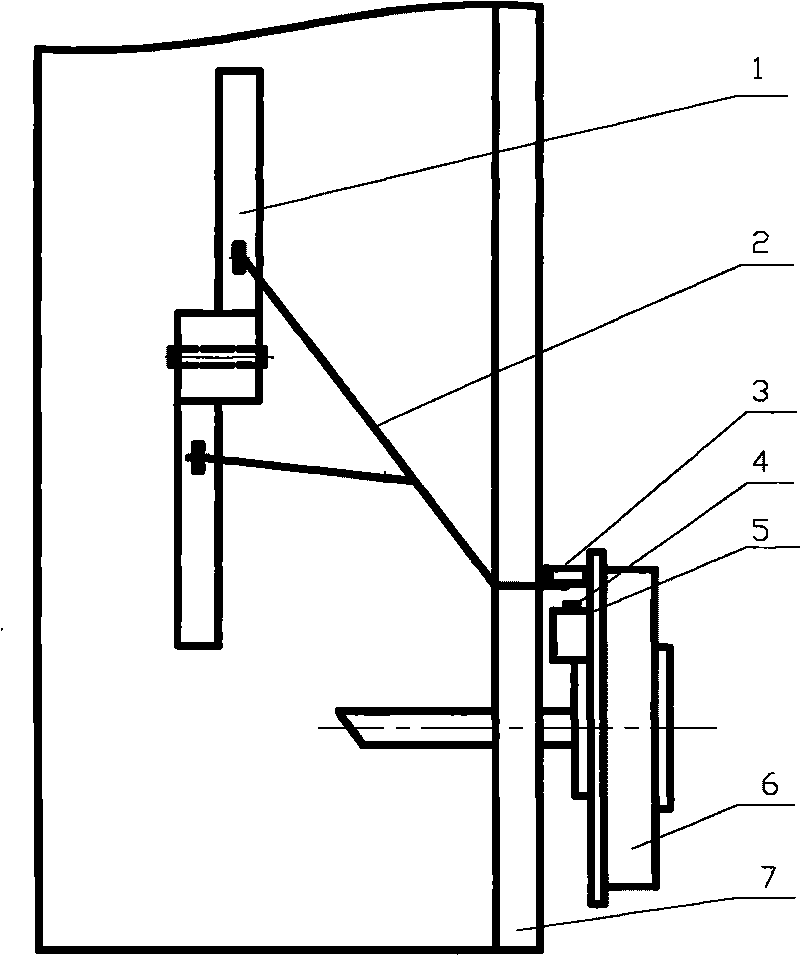

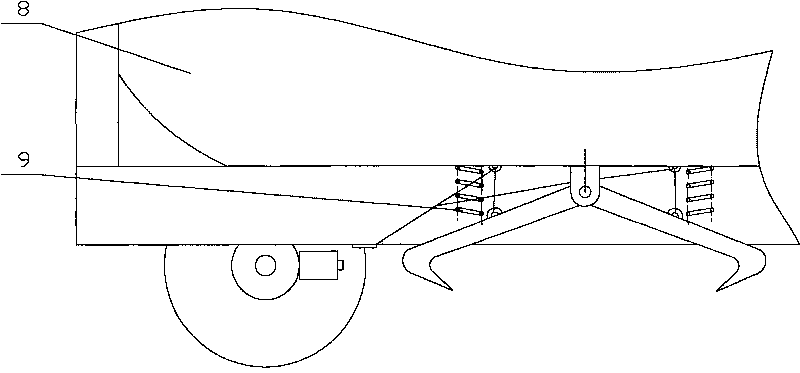

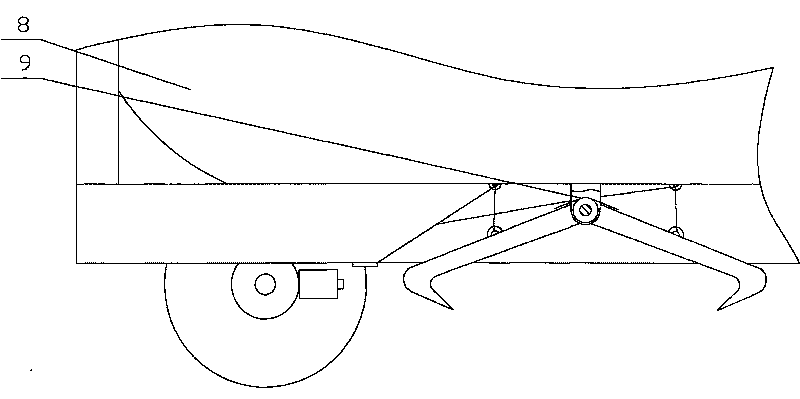

[0018] exist Figure 1 to Figure 5 In the shown embodiment, two brake pawls (1) with opposite braking directions are installed on the vehicle frame (7), and are connected to the brake pawl release plate (3) through flexible ropes (2), so that the brake pawls The movable claw is suspended at the bottom of the mine car, and the wheel (6) is equipped with a slider mounting seat (5), and the slider (4) is installed in the slider mounting seat, and can move back and forth in the mounting seat. When the mine car is in normal operation, , the centripetal force required for the slider to rotate with the wheel is in balance with the elastic force generated by the spring (10). When the mine car overspeeds, the centripetal force required for the slider increases, and the spring (10) is compressed. When the centripetal force increases to a certain value, the slider The block protrudes from the mounting seat and collides with the pawl release plate (3), causing the pawl release plate (3) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com