Central control device of well drilling winch in vertical shaft construction

A technology of centralized control and control device, applied in the direction of hoisting device, clockwork mechanism, etc., can solve the problems of wasting manpower, broken rope accidents, increasing wage expenses, etc., to improve construction efficiency, high safety factor, and manpower saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

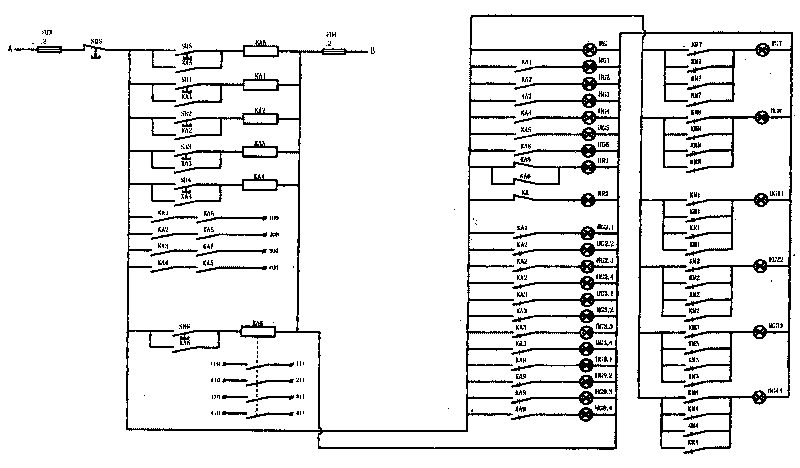

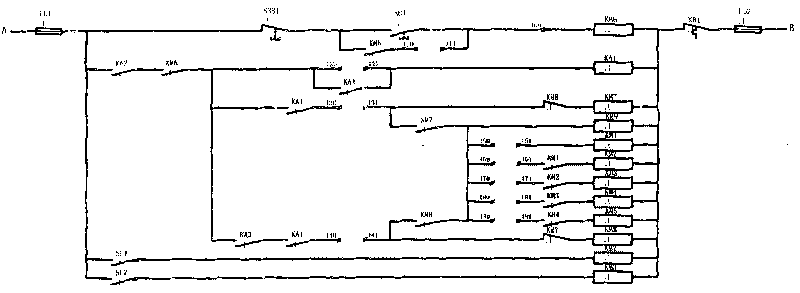

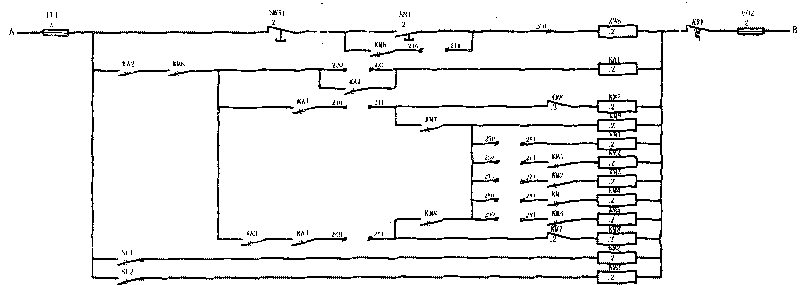

[0029] A centralized control device for sinking winches in vertical shaft construction, comprising a centralized control selection button SB5, an on-site control selection button SB6, a plurality of single shaft construction drilling winch selection buttons SBn and a plurality of single shaft construction selection buttons SBn arranged in a centralized control cabinet The construction sinking winch control device is composed of centralized control selection button SB5, local control selection button SB6 and multiple single shaft construction drilling winch selection buttons SBn connected in parallel between A and B terminals of the power supply. There are input fuse FU3.2 and centralized control stop button SBS in series at the power supply end, and output fuse FU4.2 is connected in series at the B end of the power supply. In the centralized control selection button SB5, local control selection button SB6 and multiple single units On the branch of shaft construction winch selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com