Three-dimensional mechanical property tester for fabric and textile structural composite materials

A technology for textile structures and composite materials, which is applied in the direction of testing the strength of materials using a single impact force and testing the strength of materials using a stable tension/pressure application. Effects of strain properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

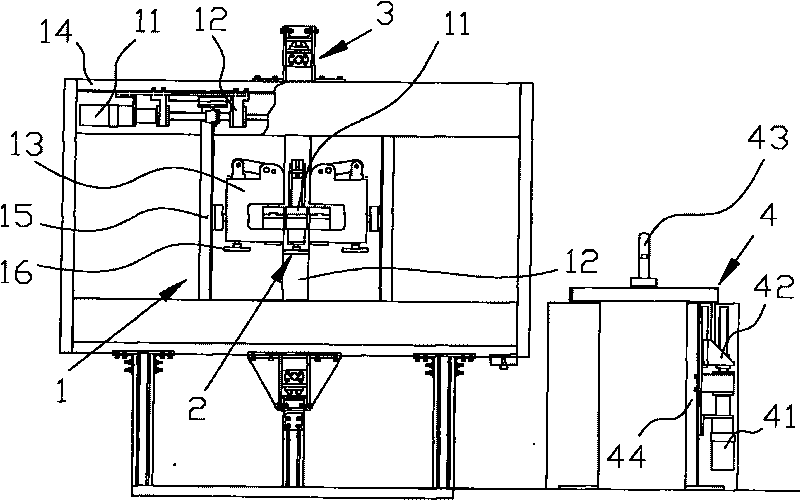

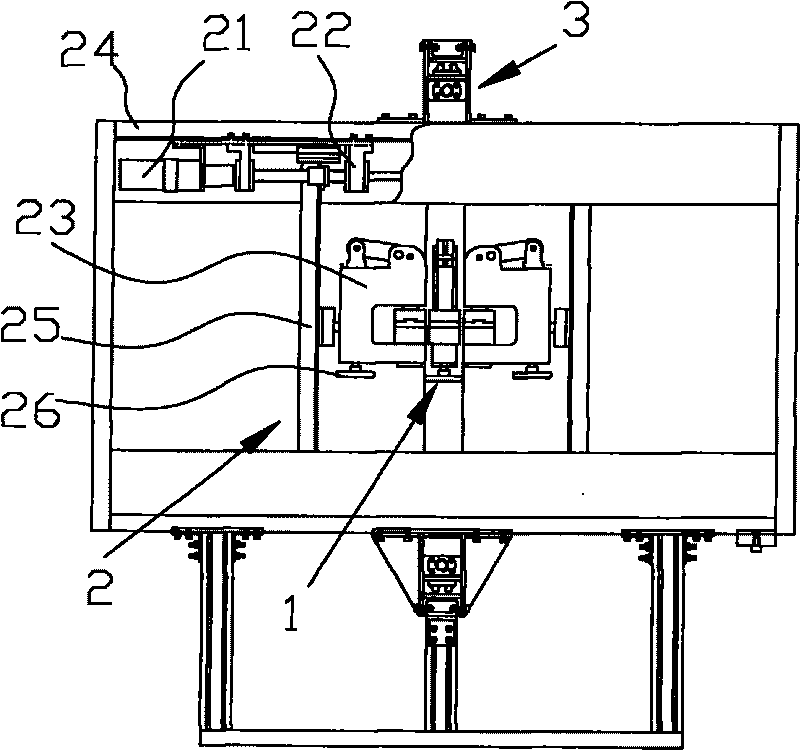

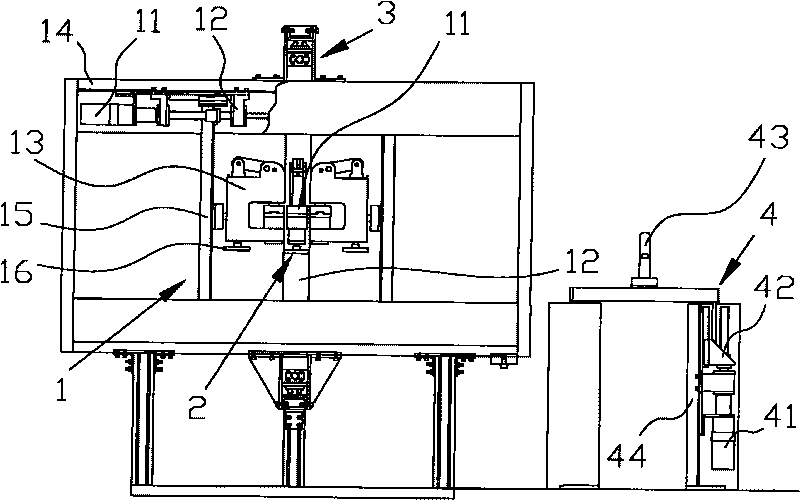

[0017] like figure 1 As shown, the present invention includes: an X-axis tension-compression unit 1, a Y-axis tension-compression unit 2, a vertical burst unit 4 and a digital speckle (DSCM) test unit 3; wherein, the X-axis tension-compression unit 1 is used for the material to be tested performed in the X-axis (at figure 1 The tension and compression in the left and right directions); the Y axis tension and compression unit 2 is used for figure 1 The vertical bursting unit 4 is used for the material to be tested to be stretched along the X-axis and the Y-axis when the material to be tested is stretched along the plane perpendicular to the X-axis and the Y-axis. The abutment force in the direction of the X-axis and the Y-axis at an angle of 90°; the digital speckle (DSCM) test unit 3 is used to measure the deformation process and failure trend of the material to be tested under force.

[0018] The above-mentioned vertical bursting unit 4 includes: a vertical bursting head 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com