Insulating supporting rod for high-voltage electrical appliance and production method thereof

A technology for high-voltage electrical appliances and insulation support, applied in insulators, insulators, circuits, etc., can solve the problems of complex production process, low insulation performance, easy to break, etc., and achieve the effect of high structural strength and good insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

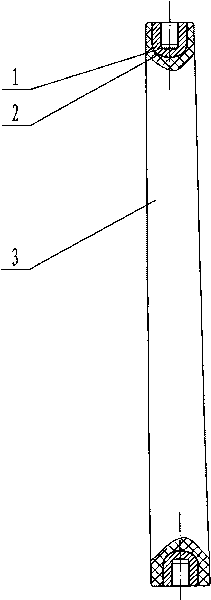

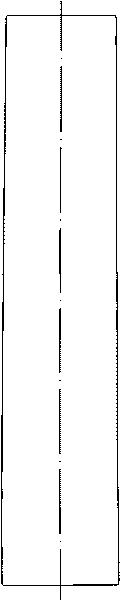

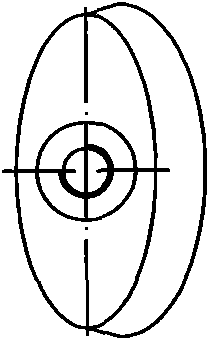

[0012] Such as Figure 1-3 The shown insulating support rod for high-voltage electrical appliances includes an epoxy resin rod body 3 and two metal inserts 1, and the two metal inserts 1 are respectively embedded in the two ends of the epoxy resin rod body 3, and the epoxy resin rod body 3 The upper and lower end faces are parallel, the angle between the center line of the upper and lower end faces and the vertical line of the end face is 0-15°, preferably 6°, the shape of the metal insert 1 is cylindrical, and the metal insert 1 has an inner A semi-conductive rubber layer 2 with a thickness of 0.5-0.6 mm is provided between the thread, the metal insert 1 and the epoxy resin rod body 3 .

[0013] The cross section of the epoxy resin rod body 3 is oval, and the epoxy resin rod body 3 gradually becomes thinner from one end to the other end.

[0014] The production method of the above-mentioned insulating support rod for high-voltage electrical appliances includes the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com