Charging and discharging manipulator for heat treatment

A technology of reclaiming manipulator and trolley

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

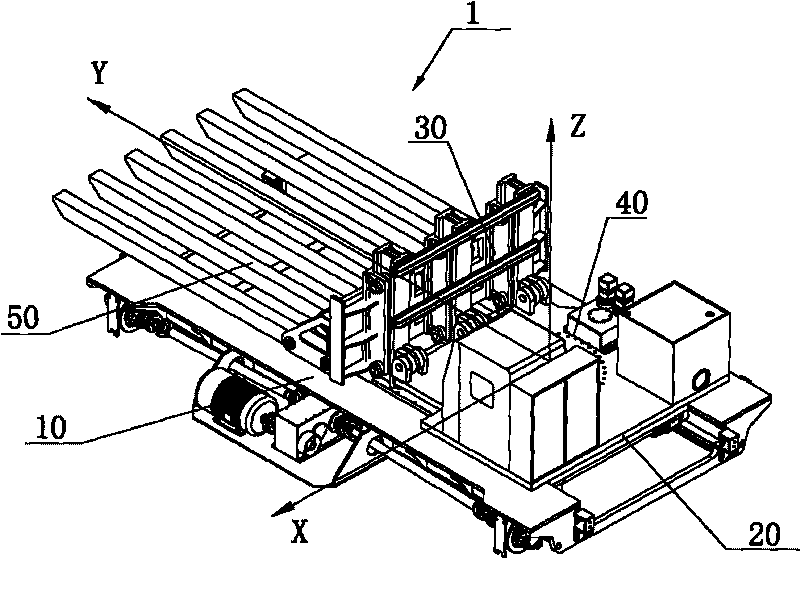

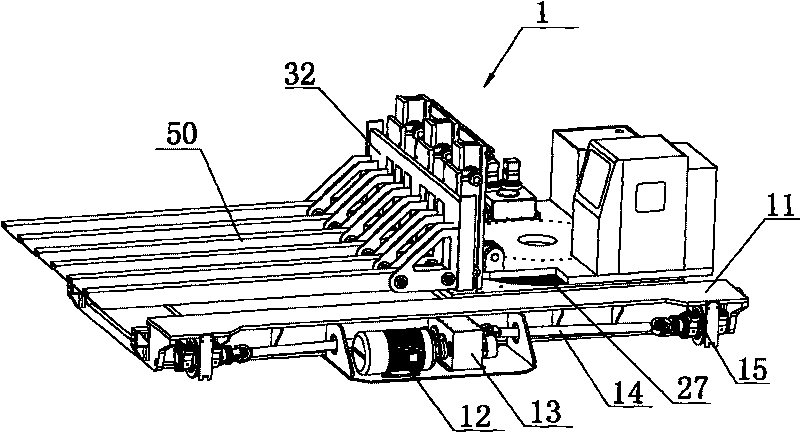

[0043] Such as figure 1 and figure 2 As shown, a loading and unloading manipulator 1 for heat treatment includes a cart part 10 that moves horizontally, a trolley part 20 that moves longitudinally on the cart part 10, and moves up and down on the trolley part 20 The lifting part 30 is provided with a fork handle group part 50 on the lifting part 30 , and a turning part 40 is also provided on the lifting part 30 .

[0044] According to the relative positional relationship between the heating furnace 2 and the heat treatment pool 3, when the rotation of the fork handle assembly part 50 is not required, the turning part 40 may not be provided.

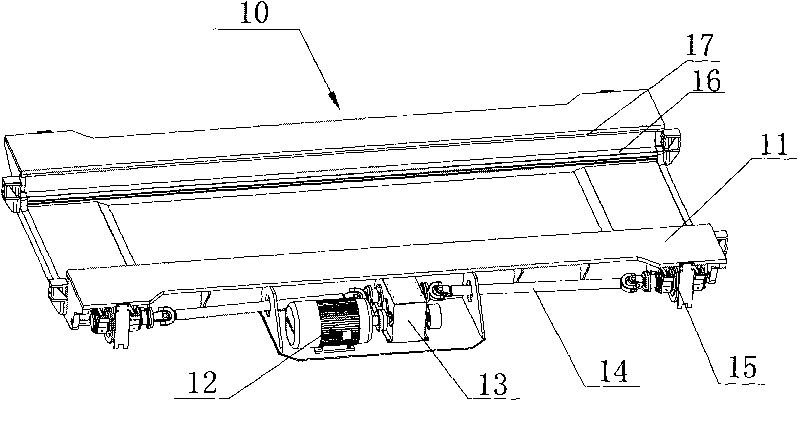

[0045] Such as image 3 As shown, the cart part 10 that translates in the transverse direction includes a cart pan 11, and a power part is arranged at the bottom of the cart pan 11, including a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com