Stone laying and leveling installation system and laying method

An installation system and stone technology, applied in the processing of building materials, floors, buildings, etc., can solve the problems of not being able to guarantee a successful leveling, increase hidden costs, and increase laying costs, so as to achieve a humanized and improved paving process. Labor productivity and labor cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

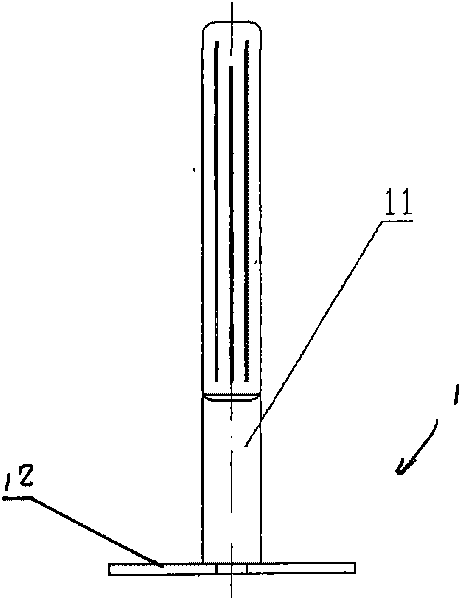

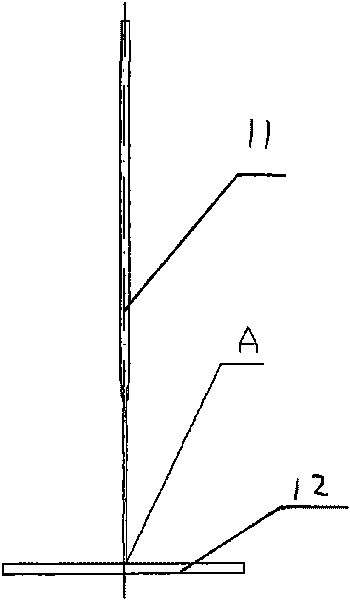

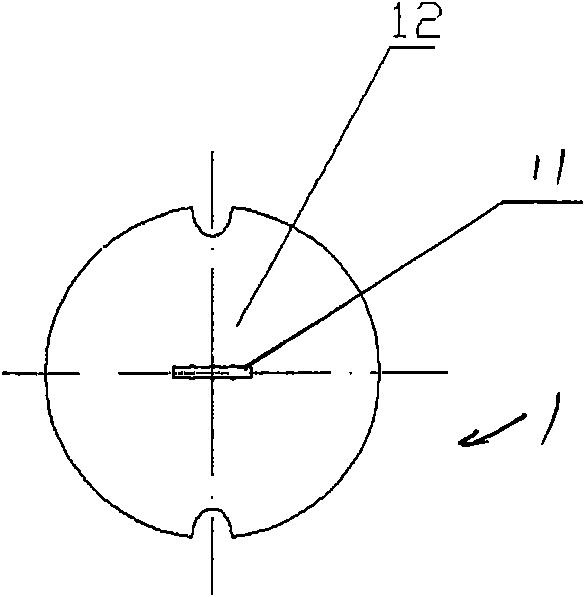

[0060] see figure 1 It is a schematic diagram of the front view structure of the plastic belt of the present invention, figure 2 It is a side view structural schematic diagram of the plastic belt of the present invention, image 3 It is a top view structure schematic diagram of the plastic belt of the present invention, Figure 4 It is a schematic diagram of the front view structure of the plastic seat of the present invention, Figure 5 for Figure 4 A-A cutaway view and see Figure 11 It is a schematic diagram of the assembly structure during the paving process of the leveling system of the present invention, a stone laying leveling installation system, including a plastic belt 1, a plastic seat 2 and a clamp 6, wherein:

[0061] The plastic belt 1 is composed of a flat belt body 11 and a base 12 at the bottom of the belt body. The belt body 11 passes upwards from the gap between two adjacent leveling stones 3, 3', and is covered by two leveling stones 3, 3'. Clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com