Photo-induced polymer holographic material mixed with nano-silicon dioxide and preparation method thereof

A nano-silicon dioxide and photopolymer technology, which is applied in the field of optical holographic storage, can solve the problems of not being able to meet the large refractive index modulation degree and high spatial stability at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

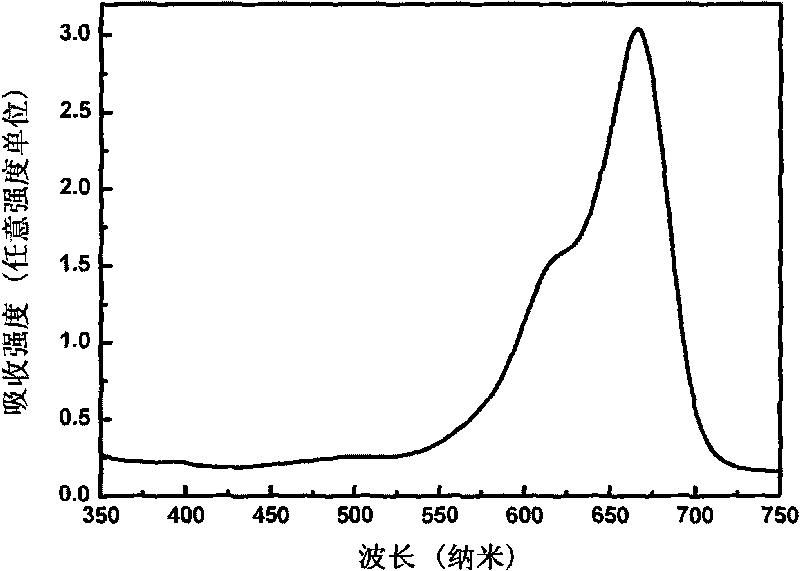

[0018] Example 1: Prepare according to the above-mentioned specific preparation process, and the final dry film component content of the photopolymer prepared is:

[0019] Polyvinyl alcohol: 47.133wt%

[0020] Acrylamide: 14.100wt%

[0021] N,N’-methylenebisacrylamide: 3.924wt%

[0022] Triethanolamine: 31.643wt%

[0023] Methylene blue: 0.076wt%

[0024] Nano silica particles: 3.124wt%

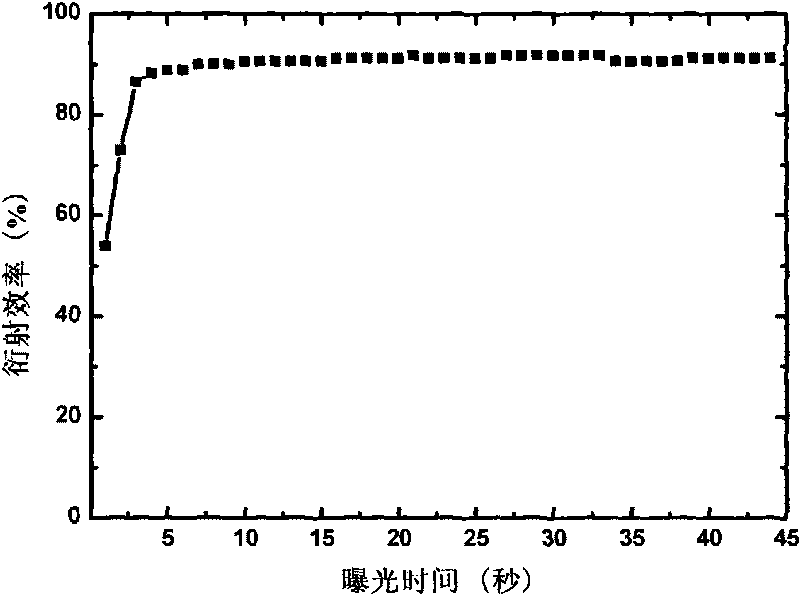

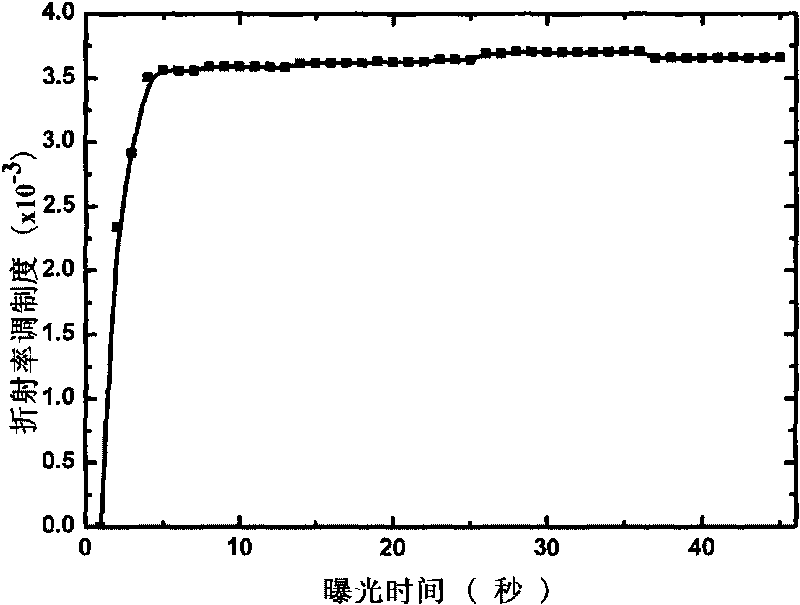

[0025] Such as figure 2 As shown, the obtained diffraction efficiency can reach 93%.

Embodiment 2

[0026] Example 2: Prepare according to the above specific preparation process, and the final photopolymer film component content is:

[0027] Polyvinyl alcohol: 47.562wt%

[0028] Acrylamide: 14.228wt%

[0029] N,N’-methylenebisacrylamide: 3.959wt%

[0030] Triethanolamine: 31.929wt%

[0031] Methylene blue: 0.077wt%

[0032] Nano silica particles: 2.254wt%

[0033] The diffraction efficiency obtained in this embodiment can reach 88%.

Embodiment 3

[0034] Example 3: Prepare according to the above specific preparation process, and the final photopolymer film component content is:

[0035] Polyvinyl alcohol: 46.632wt%

[0036] Acrylamide: 13.951wt%

[0037] N, N`-methylenebisacrylamide: 3.882wt%

[0038] Triethanolamine: 31.307wt%

[0039] Methylene blue: 0.0755wt%

[0040] Nano silica particles: 4.153wt%

[0041] The diffraction efficiency obtained in this embodiment can reach 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com