Foam tool

A technology of tools and molds, which is applied in the field of foaming tools, can solve problems such as cost increase, liquid outlet wear, and difficulty in cleaning, and achieve the effects of increasing foaming volume and quality, prolonging service life, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

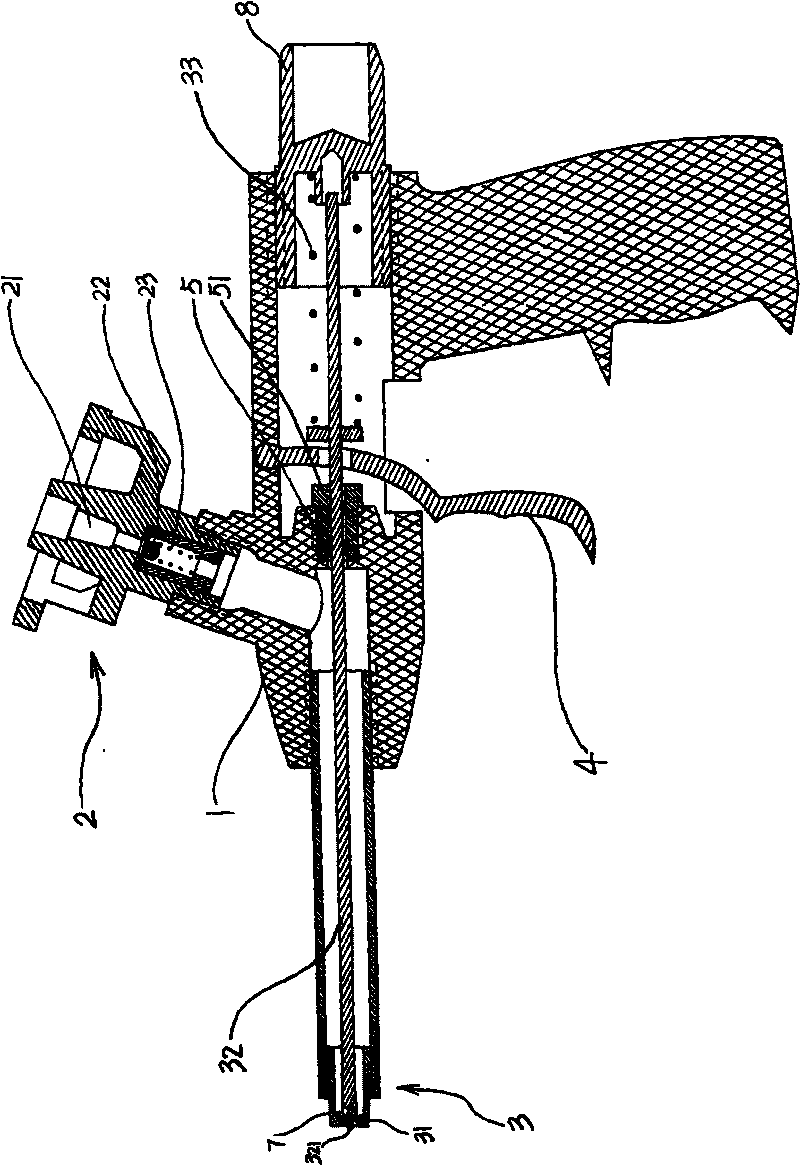

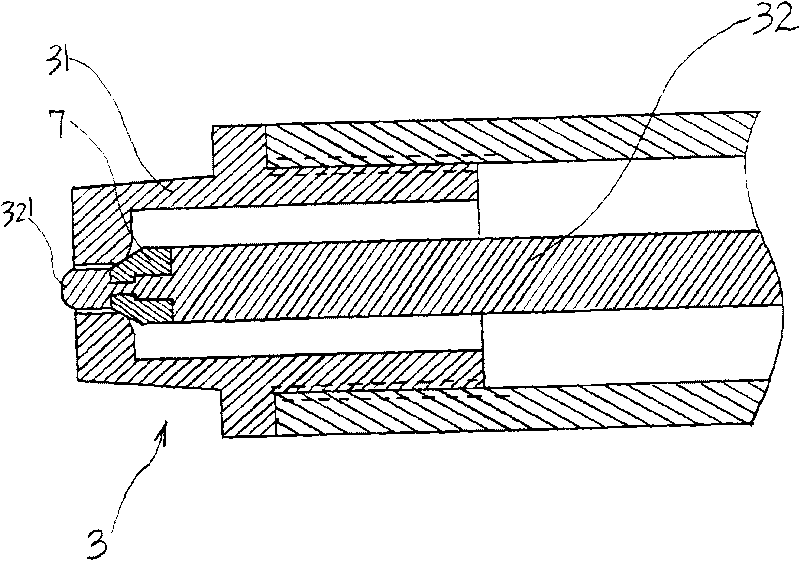

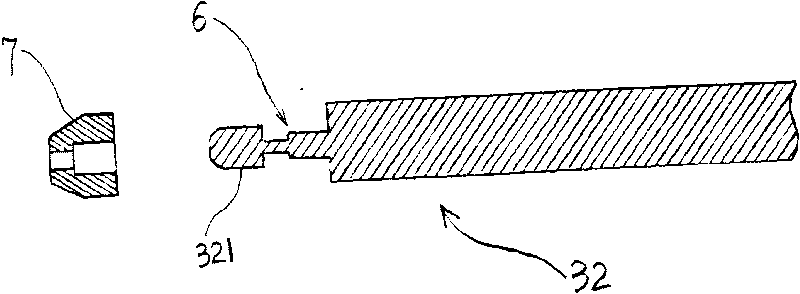

[0035] Foaming tool of the present invention, it comprises gun body 1, liquid inlet valve 2, liquid outlet valve 3 and switching device 4, and liquid outlet valve 3 comprises liquid outlet nozzle 31, valve core 32 and back-moving spring 33, and switching device 4 can make The liquid outlet valve 3 is opened or closed, for example, the valve core 32 has at least a part of the inner passage extending out of the foaming tool, so that the switch device 4 can directly or indirectly act on the valve core 32, wherein the valve core 32 A recess 6 is set on the head, and a sealing ring 7 is arranged in the recess 6, the sealing ring 7 is sealed with the liquid outlet nozzle 31, and at least part of the head 321 of the valve core 32 exposes the sealing ring 7, effectively preventing and avoiding It prevents the leakage and / or solidification of the foam sealant in the foaming tool, effectively prevents the channel from being blocked, and effectively prevents and avoids the leakage or comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com