analog switch

A technology of analog switch and analog screen, which is applied in the direction of electrical components, supervision desk/panel, etc., to achieve the effect of simple mechanism and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

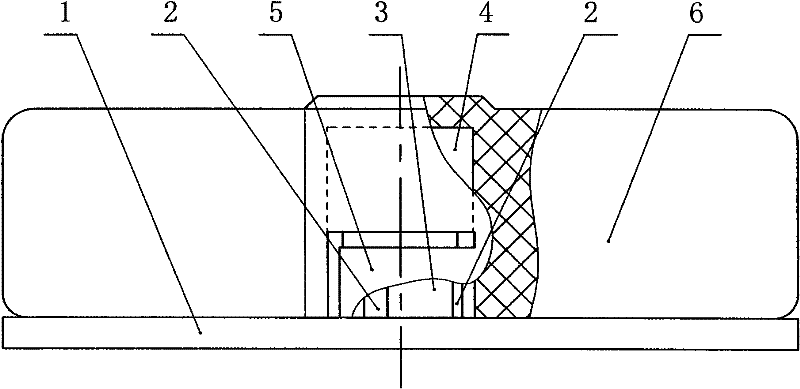

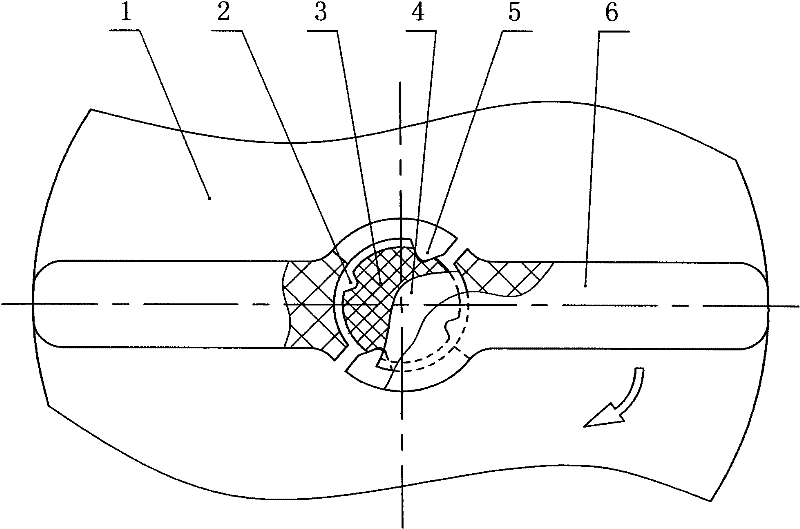

[0016] Embodiment one: figure 1 , figure 2 As shown, one side of the base plate 1 is provided with glue that is connected to the surface of the analog screen, and the other side of the base plate 1 is connected with one end of a small-diameter shaft 3 with a step shaft, and two to ten ends are arranged on the outer wall of the small-diameter shaft 3. There are two positioning slots 2 , and one to three elastic buckles 5 that can be snapped into the positioning slots 2 are provided on the hole wall of the button handle 6 .

Embodiment 2

[0017] Embodiment two: image 3 , Figure 4 As shown, the inner wall of the end of the step hole of the button handle 6 is provided with two to twelve grooves 7 . One side of the bottom plate 1 is provided with glue that connects with the surface of the analog screen, and the other side of the bottom plate 1 is connected with one end of a small-diameter shaft 3 of a stepped shaft, and the outer wall of the large-diameter shaft 4 of the stepped shaft is provided with one to four clips. The protruding teeth 11 that enter the groove 7, and the periphery of each protruding tooth 11 is provided with an elastic escape slit 10. Between small-diameter shaft 3 and button handle 6 holes, be provided with the cover 9 that closely matches with button handle 6.

Embodiment 3

[0018] Embodiment three: Figure 5 , Figure 6 , Figure 7 As shown, one side of the bottom plate 1 is provided with glue connected to the surface of the analog screen, and the other side of the bottom plate 1 is connected with a small-diameter shaft 3 with a stepped shaft. The outer wall of the small-diameter shaft 3 is provided with four to eight opposite sides. parallel planes. Open seams 12 are provided on both sides of the button handle 6 holes, and spring buckles 8 are arranged in the seams 12, and the spring buckles are stuck on one group of opposite side surfaces in four to eight opposite side parallel surfaces. The spring buckle is formed by bending the elastic material into a semicircle, and the two ends are bent inward and parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com