Rotator for welding box-shaped structural member

A technology of structural parts and welding boxes, which is applied in the field of rotating machines, can solve the problems of increased difficulty and danger, poor quality of welds, and many operators, and achieve the effects of saving manpower and material resources, convenient operation and labor-saving, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

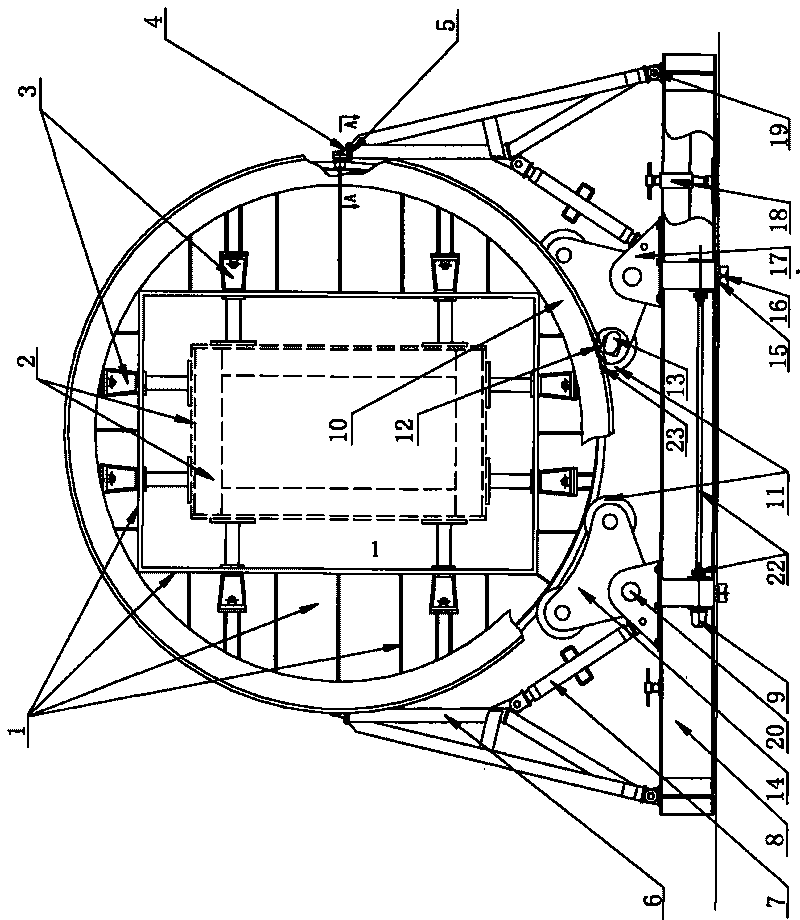

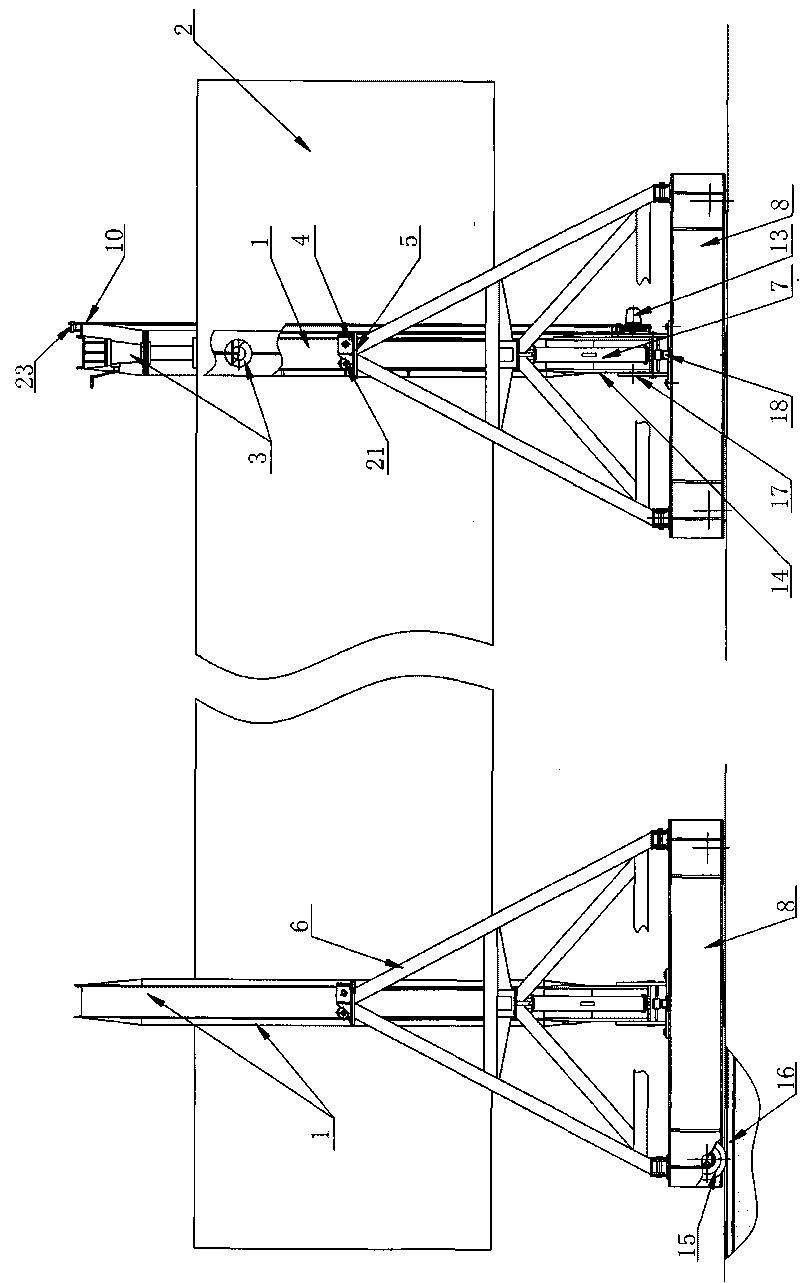

[0044] Such as figure 1 and figure 2 As shown, this embodiment discloses a rotary machine for welding box-shaped structural parts, which mainly consists of the following components:

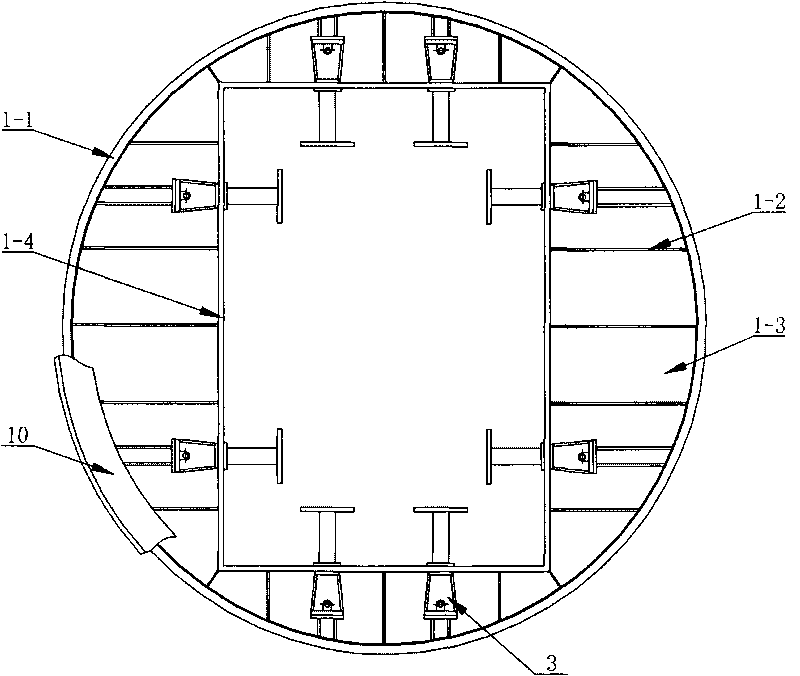

[0045] Two rotating track support mechanisms 1, each of which includes a ring-shaped grooved track 1-1 and a rectangular frame 1-4 structure in its ring. The annular grooved track 1 is a ring structure with a "匚"-shaped cross section, and its groove is on the outer ring. Such as image 3 As shown, the rotating track support mechanism 1 and the rectangular frame 1-4 are connected and fixed by the main rib 1-3 on the same plane with them, and the main rib 1-3 is provided with a reinforcement for fixing Several stiffener plates 1-2, said stiffener plates 1-2 include transverse, longitudinal and oblique arrangement. There are at least two rotating rail support mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com