Large-diameter explosive paper drum-rolling machine and rolling method

A paper reel and large-diameter technology, applied in the field of large-diameter explosive paper reel machines and reeling methods, can solve the problems of low production efficiency, inability to wax, complex structure, etc., and achieves strong practicability, novel design, paper The effect of the barrel specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

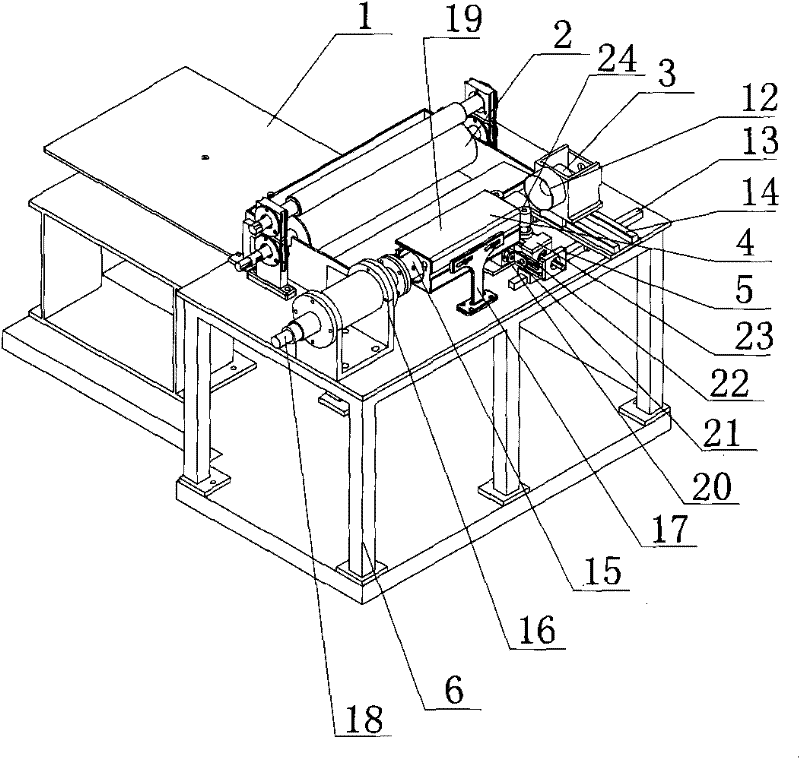

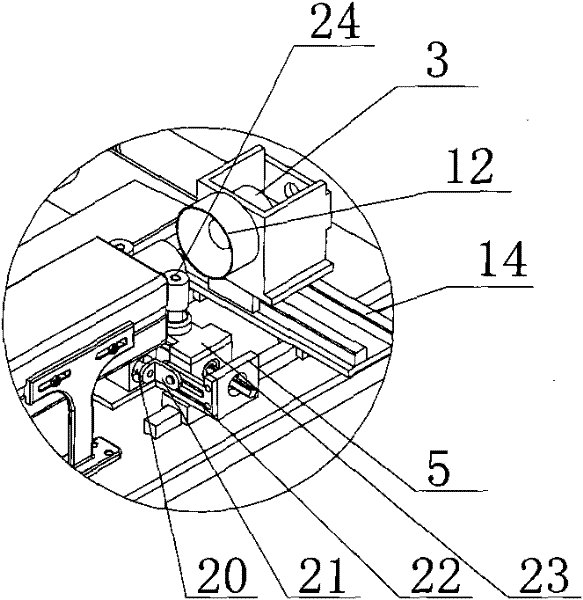

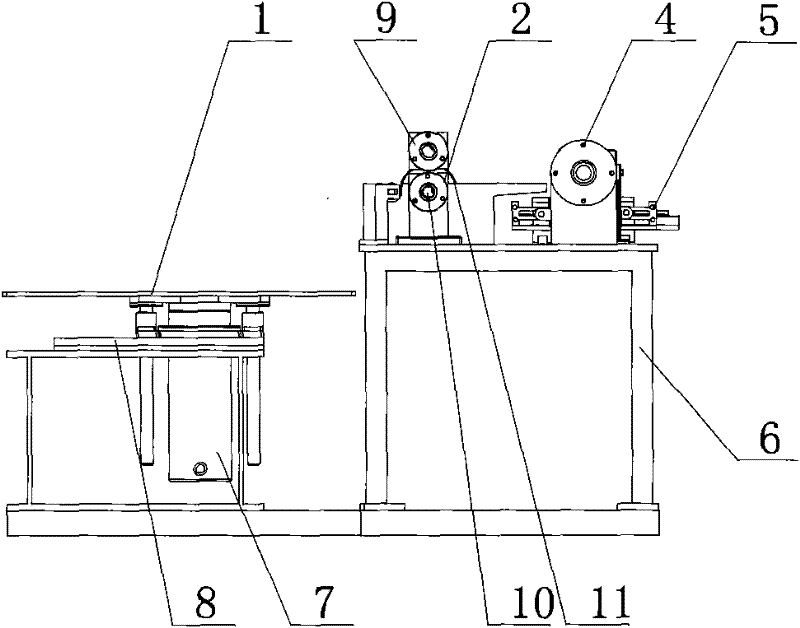

[0012] Embodiment 1: with reference to attached Figure 1 ~ Figure 4 . The large-diameter explosive reel machine includes a programmable controller, and the production of the programmable controller is a prior art, so it is not described here. The large-diameter explosive reel machine is composed of a paper feeding mechanism 1, a waxing mechanism 2, a bottoming mechanism 3, a reel mechanism 4, a rewinding mechanism 5, and a frame 6; the paper feeding mechanism 1 is located on the side of the waxing mechanism 2 And cooperate with the entrance in the waxing mechanism 2, the entrance in the waxing mechanism 2 and the entrance of the reel mechanism 4 are combined, and one end of the reel mechanism 4 cooperates with the bottoming mechanism 3, and one side is set in the reel mechanism 4 There is a roll back mechanism 5, and the negative pressure suction drive shaft 18 communicates with the roll mechanism 4.

[0013] The paper feeding mechanism 1 is composed of an oil cylinder 7, a...

Embodiment 2

[0019] Embodiment 2: on the basis of embodiment 1, the reel method of large-diameter explosive reel machine, it comprises programmable controller, it is characterized in that: at first set instruction according to reel step, programmable controller according to According to the set instruction, when the oil cylinder 7 in the paper feeding mechanism 1 is instructed to send the paper feeding pallet 8 with paper to the position opposite to the paper inlet of the waxing mechanism 2, the programmable controller instructs the paper feeding manipulator to feed the paper into the The paper inlet formed by the waxing roller 10 and the paper delivery roller 9 in the waxing mechanism 2 is used for waxing. After the waxing is completed, the programmable controller sends the waxed paper to the open cylinder 19 in the reel mechanism 4. At the moment when the inlet is adsorbed on the suction paper tube 15 and rolled into a paper tube, the longitudinal cylinder located in the roll mechanism 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com