Method for preparing rubusoside by stevioside

A technology of steviol glycoside and rubusoside, which is applied in the field of food additive application, can solve the problems of high price, insufficient raw materials, low product purity, etc., and achieve the effect of solving the limited source of raw materials and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

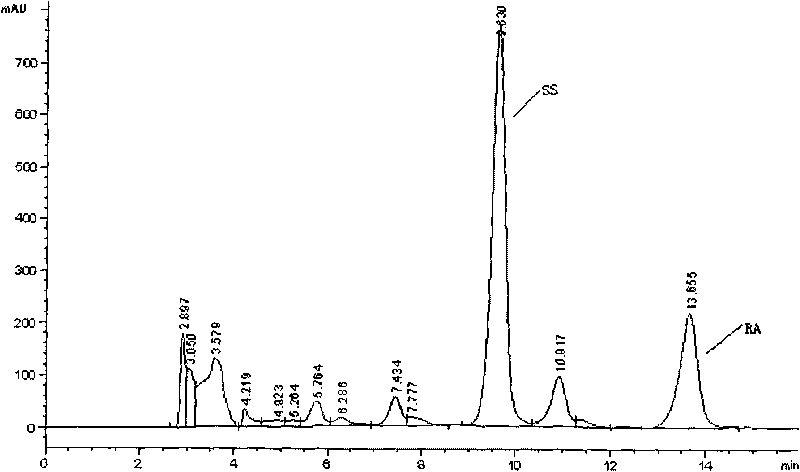

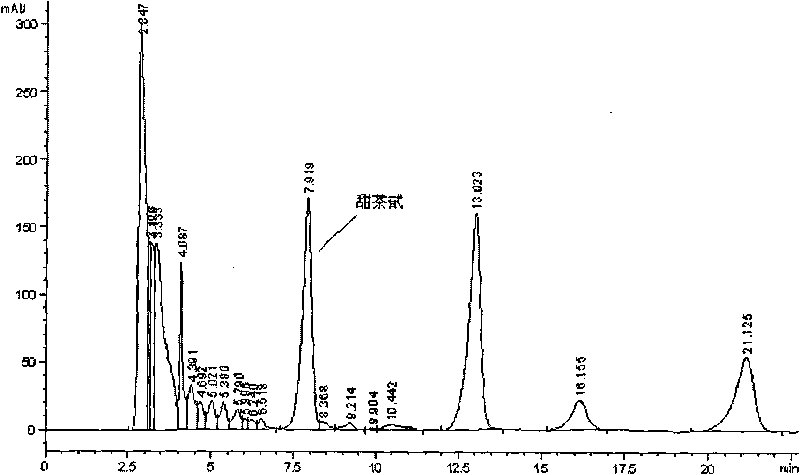

Embodiment 1

[0043] Prepare 1% (W / W), pH 7.5 stevioside (SS accounted for 72%, RA accounted for 25%) transformation substrate, insert 10% (V / V) JH bacterial solution, 30°C, 200r / min dynamic culture 3 sky. After the cultivation, the bacteria were removed by centrifugation at 5000rpm. The supernatant was flocculated and precipitated to remove impurities, the macroporous resin was adsorbed and separated, and the eluent was crystallized and purified to obtain high-purity rubusoside. The purity was about 95%, and the conversion rate of stevioside was 90%. %.

Embodiment 2

[0045] Put 0.01% (W / W), pH 3.5 stevioside substrate in a 500mL Erlenmeyer flask, add 0.01% (W / W) bacterial powder, and culture at 30°C for 1 day. Separation and purification to obtain high-purity rubusoside.

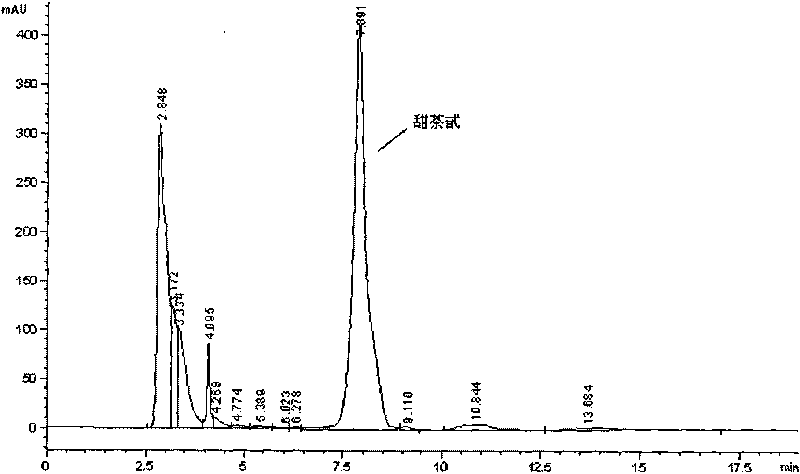

Embodiment 3

[0047] 0.05% (W / W), pH 5.5 stevioside substrate in a 500mL transformation bottle, add 1% (W / W) bacterial powder, and incubate at 30°C for 12h. After separation and purification, high-purity rubusoside is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com