Heating process of low-temperature flue gas with wetting flue gas desulphurization

A wet flue gas desulfurization and low-temperature flue gas technology, applied in lighting and heating equipment, etc., can solve the problems of unstable desulfurization performance, poor heating effect, uneconomical operation, etc., so as to improve the lifting and diffusion effect and reduce power consumption. , the effect of flexible adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

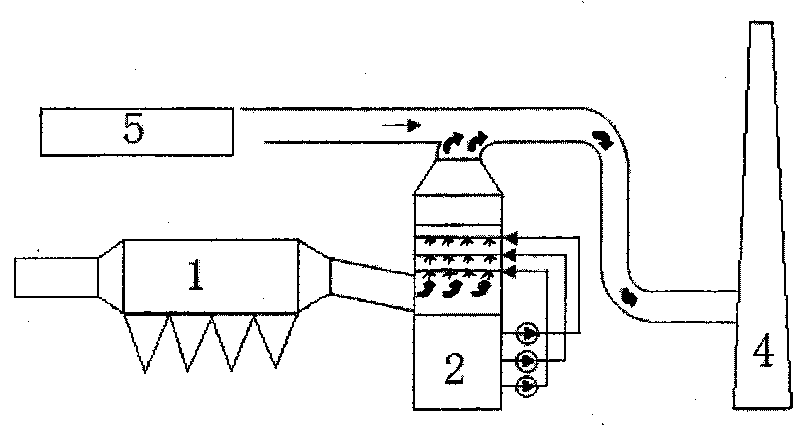

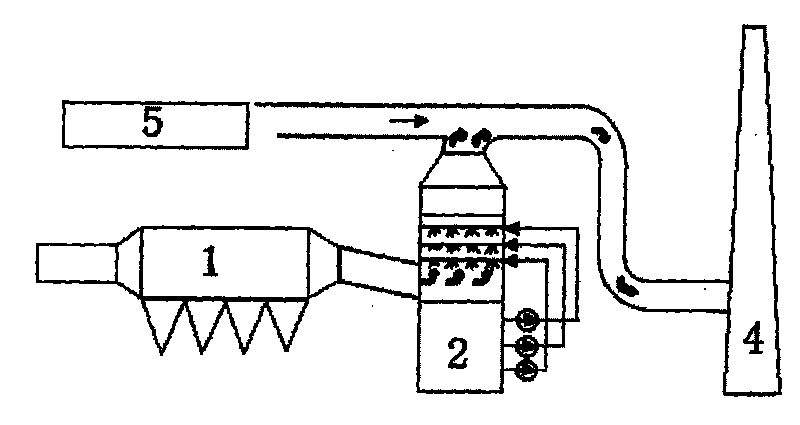

[0010] Example 1, see figure 1 , the present invention removes the GGH, the outlet of the absorption tower is directly connected to the chimney through a pipeline, and the hot secondary air of the boiler air preheater for heating the low-temperature flue gas at the outlet of the absorption tower is connected to the pipeline connecting the absorption tower and the chimney The hot secondary air pipe of the boiler air preheater is also equipped with a hot secondary air regulating valve. Its operation process is as follows: the flue gas enters the absorption tower 2 after passing through the dust collector 1, and the low-temperature flue gas desulfurized by the absorption tower 2 goes to the chimney 4 through the pipeline. The pipeline connected to the chimney 4 is connected with the hot secondary air pipe 5 of the boiler air preheater for heating the low-temperature flue gas at the outlet of the absorption tower, and the low-temperature flue gas is heated to the required temperat...

Embodiment 2

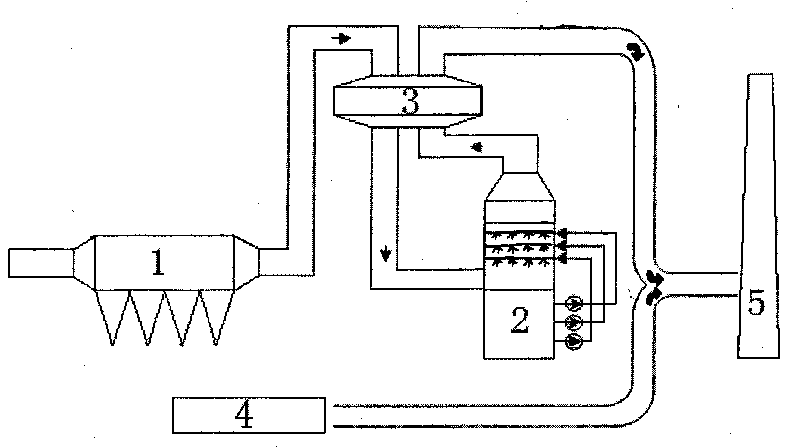

[0011] Example 2, see figure 2 , the present invention retains GGH, and changes the original GGH heat exchange element into a plate-type GGH heat exchange element with a larger gap, but the effect of heat exchange is reduced in this way. It is connected to the hot secondary air pipe of the boiler air pre-heater for heating the low-temperature flue gas at the outlet of the GGH, and a hot secondary air regulating valve is installed on the hot secondary air pipe of the boiler air pre- A certain amount of hot secondary air is used to heat the low-temperature flue gas at the outlet of the absorption tower of the desulfurization unit to the required temperature. The operation process is as follows: the flue gas enters the large-gap flat GGH heat exchange element 3 after being dedusted by the dust collector 1 and is sent to the absorption tower 2, and the low-temperature flue gas desulfurized by the absorption tower 2 passes through the large-gap flat GGH heat exchange element 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com