High voltage dry-type current transformer and ground protection method thereof

A current transformer and grounding protection technology, which is applied in the field of grounding protectors, can solve problems such as equipment insulation breakdown, increased partial discharge of products, and potential safety hazards in grounding methods, so as to avoid breakdown and increase the reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

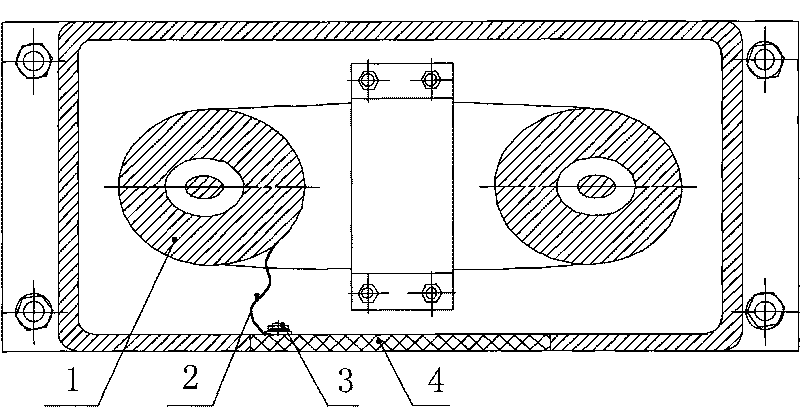

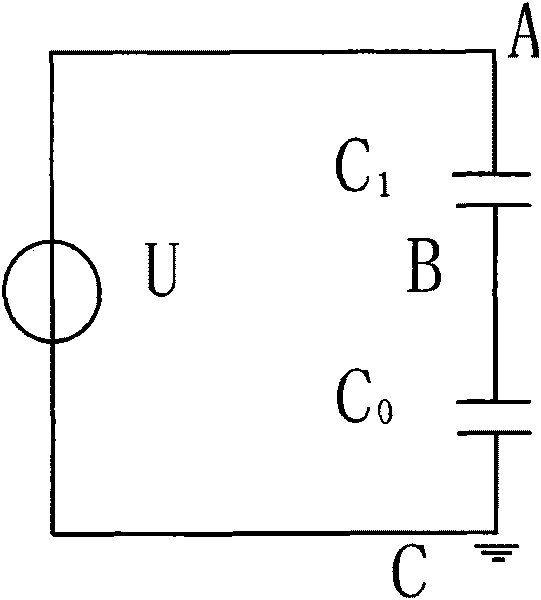

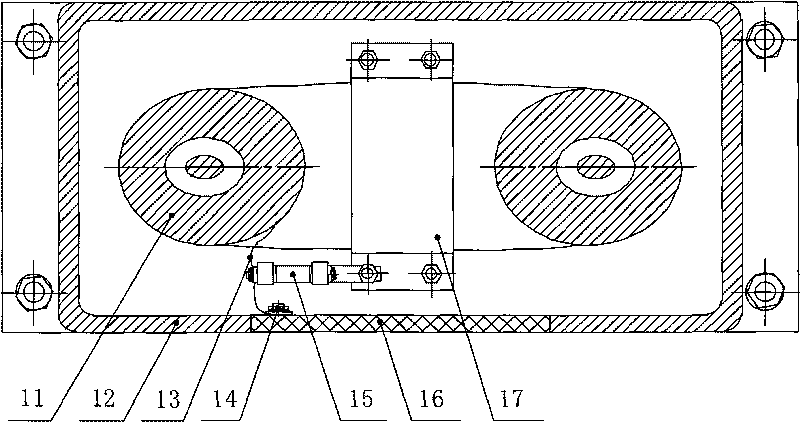

[0016] Such as image 3 , Figure 5 As shown, the high-voltage dry-type current transformer includes a housing 12, in which a primary winding 11 is fixed by a pressing plate 17, and the pressing plate 17 is fastened to the housing 12 by fixing bolts. The shell 12 is also provided with a grounding plate 16 , and the grounding plate 16 is provided with a grounding terminal 14 . A capacitive insulating layer is installed on the primary winding 11, and an end screen grounding lead 13 is provided on the end screen of the capacitive insulating layer. Two grounding branches are connected in parallel between the end screen grounding lead 13 and the casing 12, one of which is The branch circuit is directly connected to the ground terminal 14 on the casing 12 through the ground protection wire, and a ground protector 15 is connected in series in the other branch circuit. End caps 101 are sheathed, and terminal bolts 105 are respectively threaded on the caps 101 at both ends. A capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com