Electric arc automatic-welding welding fume collecting device and method for testing welding fume amount

A technology for dust collection and testing methods, which is applied to arc welding equipment, welding equipment, welding accessories, etc., can solve the problems of large influence on the stability of welding parameters, achieve accurate and effective test results, and is conducive to accurate measurement and welding parameters. The effect of small fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

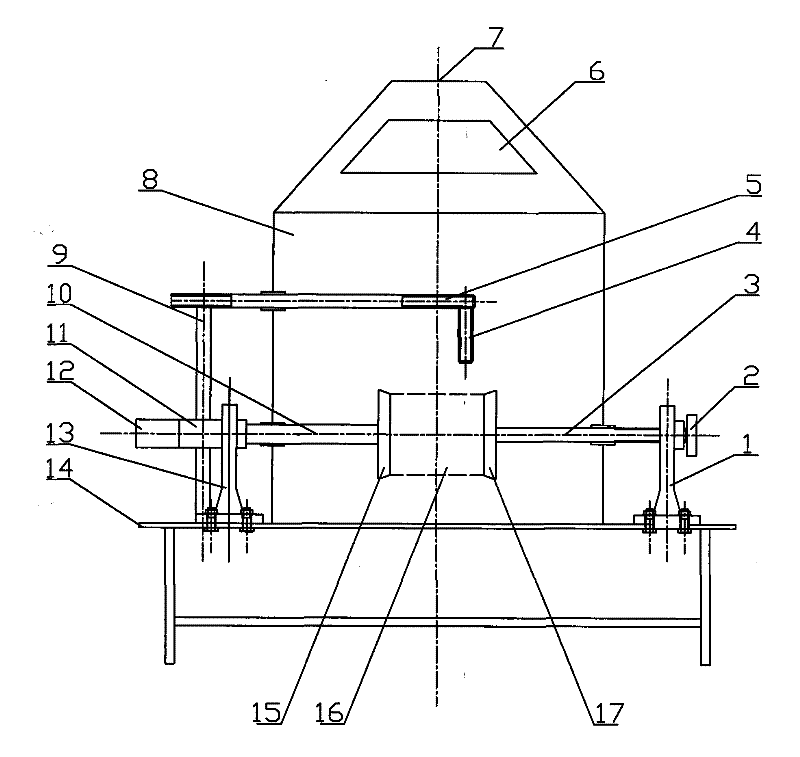

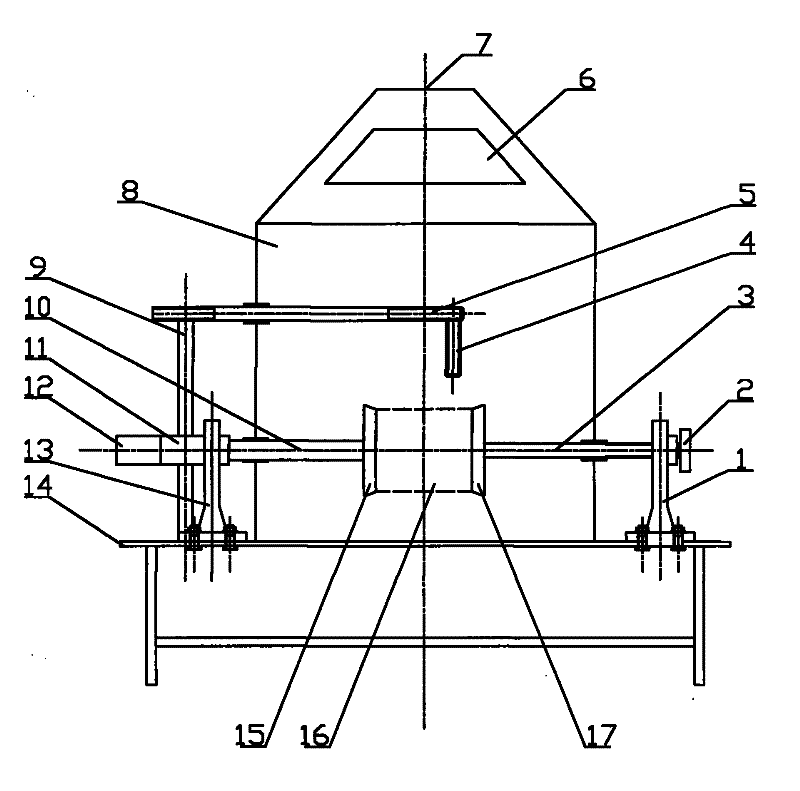

[0050] Such as figure 1 As shown, the present invention discloses a dust collection device for testing the amount of dust generated by automatic arc welding, which includes a dust collection box composed of a substantially closed box body 8, the shape of the box body 8 is not strictly limited, It can be a combination of a cuboid and a trapezoid as shown in the drawings, or a combination of a cylinder and a cone, and so on. The top of the box 8 is provided with a filter membrane 7 , the bottom of the box 8 is set on the base 14 , the box 8 is made of a material with a relative magnetic permeability less than 2, and the thickness of the box 8 is about 0.5 mm to 2 mm. The volume of the dust collection box casing 8 can not be too small, so that it is a principle to be easy to operate.

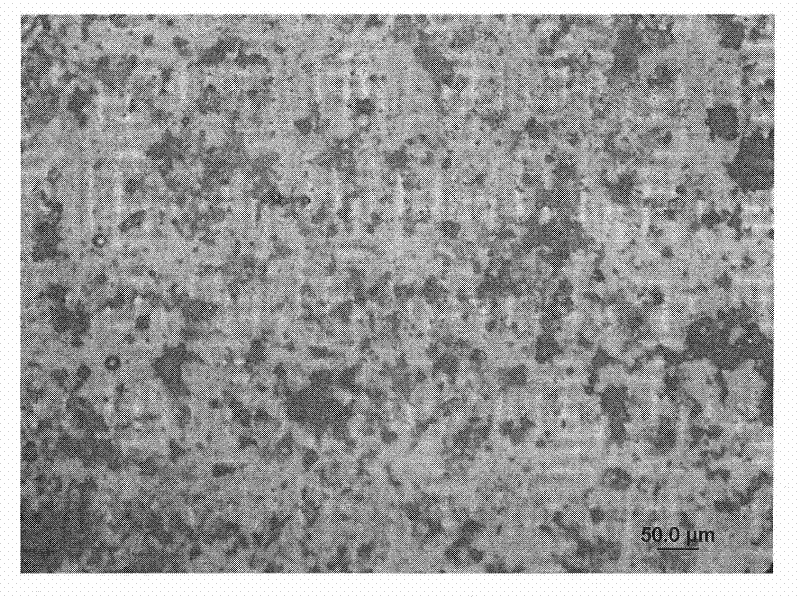

[0051] The filter membrane 7 is arranged on the top of the dust c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com