Polymer cement water-proof paint

A waterproof coating and polymer technology, which is applied in the field of polymer cement waterproof coating composition, can solve the problems of decreased softening strength, poor water resistance, and limited elongation rate, so as to reduce the poly-ash ratio, strengthen molecular strength, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare 60 parts of 25% gelatin aqueous solution at 50°C, add 0.5 parts of water reducing agent, add 30 parts of 600 mesh barite powder under stirring, and then add 1 part of 5-methyl-7-hydroxy-1.3.4 Azaindole was stirred for 60 minutes; then 1 part of 2.4-dichloro-6-hydroxy-s-triazine sodium salt (alias hardener A) was added and stirred for another 30 minutes to obtain barium sol.

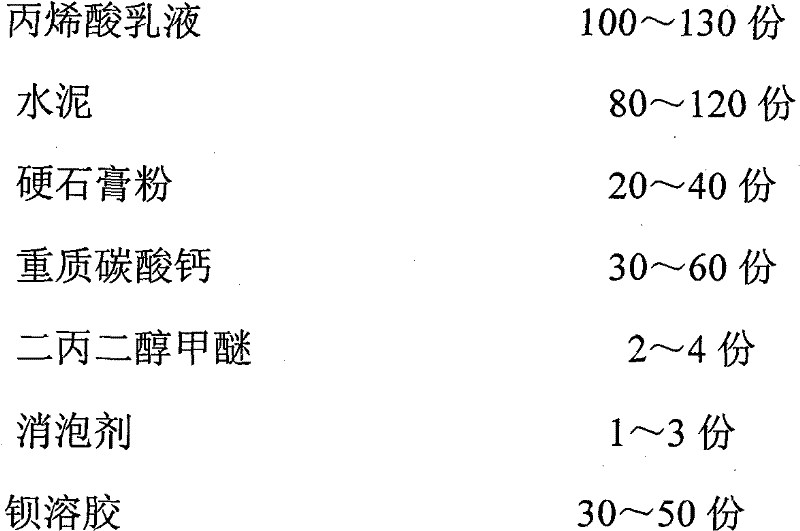

[0036] The parts by weight of components are:

[0037] 100 parts of acrylic emulsion, 120 parts of ordinary portland cement, 20 parts of anhydrite powder, 30 parts of heavy calcium carbonate, 2 parts of dibutyl phthalate, 2 parts of dipropylene glycol methyl ether, 2 parts of potassium chromate, water reducing 1 part of antifoaming agent, 1 part of antifoaming agent, 50 parts of barium sol;

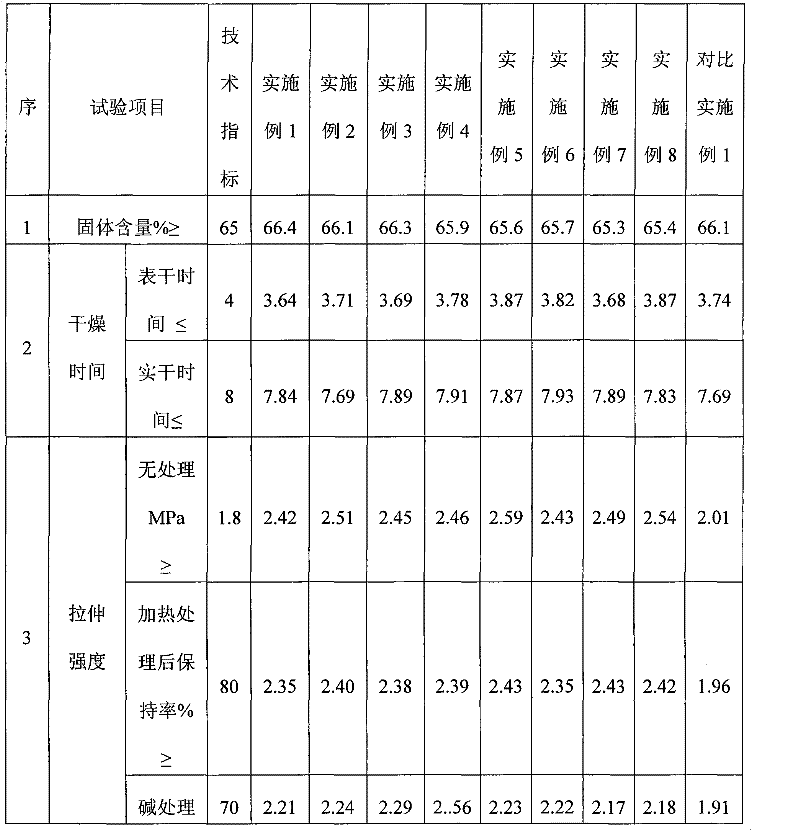

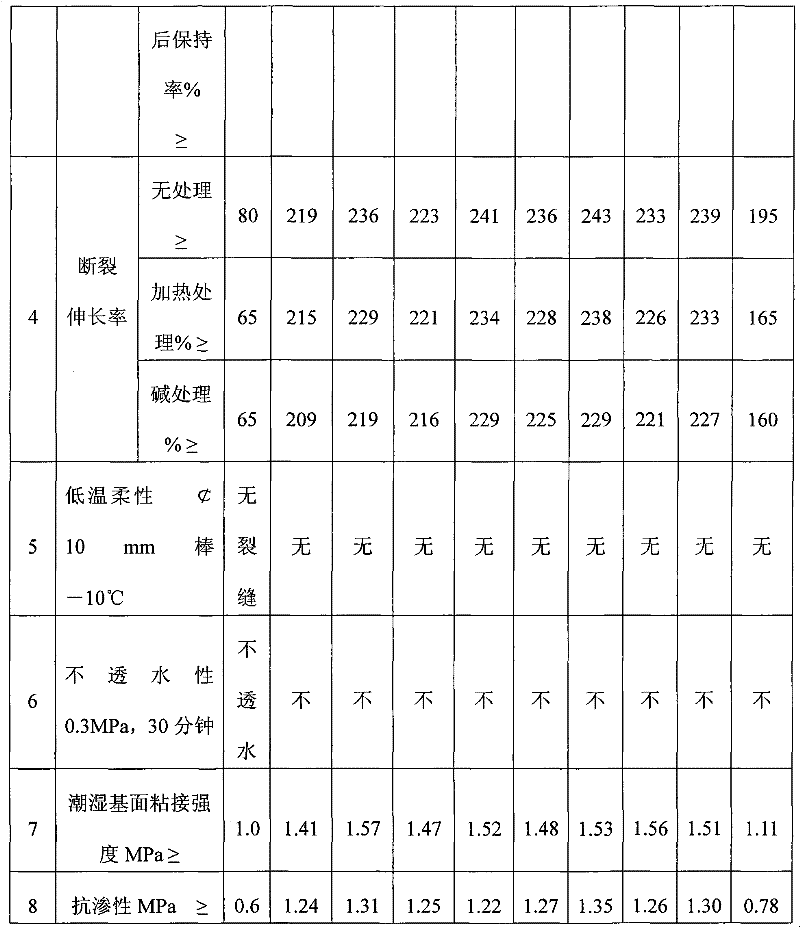

[0038] Mix each component and stir evenly to obtain the product. The test results are shown in Table 1.

Embodiment 2

[0040] At 60°C, prepare 60 parts of 15% gelatin aqueous solution, add 1 part of water reducing agent, add 40 parts of 700 mesh barite powder under rapid stirring, and then add 2 parts of 5-methyl-7-hydroxyl-1.3. 4. Triazindolizine, stirred for 50 minutes; then added 1.5 parts of 2.4-dichloro-6-hydroxy-s-triazine sodium salt (alias Hardener A), and stirred for another 25 minutes to obtain barium sol.

[0041] The parts by weight of components are:

[0042] 120 parts of acrylic emulsion, 80 parts of ordinary Portland cement, 30 parts of anhydrite powder, 40 parts of heavy calcium carbonate, 3 parts of dibutyl phthalate, 3 parts of dipropylene glycol methyl ether, 3 parts of potassium chromate, water reducing 1.5 parts of agent, 1.5 parts of defoamer, 30 parts of barium sol.

[0043] Mix each component and stir evenly to obtain the product. The test results are shown in Table 1.

Embodiment 3

[0045] Prepare 60 parts of 20% gelatin aqueous solution at 70°C, add 1.5 parts of water reducing agent, add 40 parts of 800 mesh barite powder under rapid stirring, and then add 1.5 parts of 5-methyl-7-hydroxyl-1.3. 4. Triazindolizine, stirred for 40 minutes; then added 2 parts of 2.4-dichloro-6-hydroxy-s-triazine sodium salt (alias Hardener A), and stirred for another 30 minutes to obtain barium sol.

[0046] The parts by weight of the components are: 130 parts of acrylic emulsion, 90 parts of ordinary portland cement, 30 parts of anhydrite powder, 50 parts of heavy calcium carbonate, 4 parts of dibutyl phthalate, 4 parts of dipropylene glycol methyl ether, chromium Potassium acid 4 parts, water reducer 2 parts, defoamer 2 parts, barium sol 20 parts. Mix each component and stir evenly to obtain the product. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com