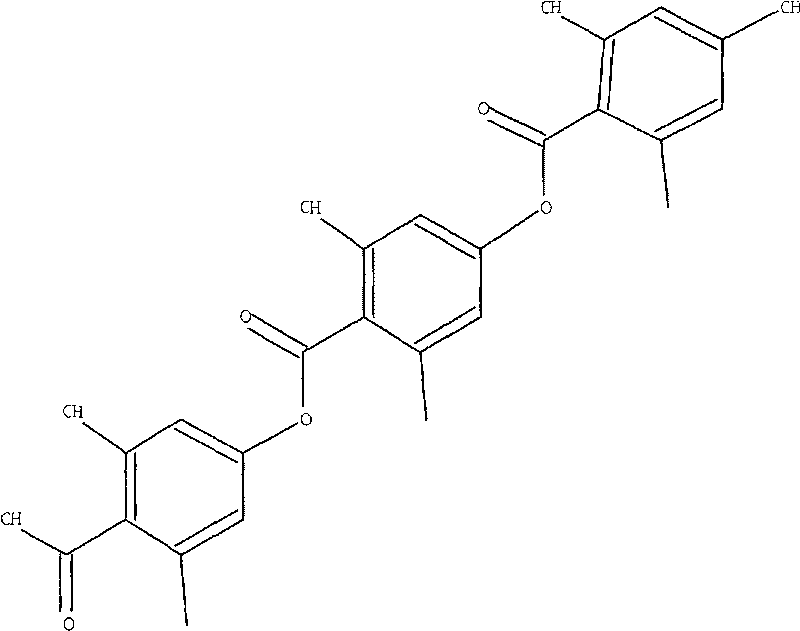

Preparation method for gyrophoric acid

A technique of scholastic acid and shironic acid, which is applied in the field of preparation of shironic acid, and can solve problems such as unfavorable large-scale production operations, low shironic acid content, serious pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take 10Kg of agaric powder, add 60% ethanol which is 5 times the volume of its weight, heat and reflux once, each time for 1 hour, combine the reflux liquid, filter, recover the ethanol under reduced pressure and concentrate, add an equal volume of acetone to extract 3 times, and combine For the acetone layer, recover the solvent and concentrate, add an equal volume of water and stir evenly, let it stand overnight, filter, take the filter residue, add acetone-ethanol (1:1) to crystallize, separate the crystals, wash and dry to obtain 258.2 g of pharylic acid. As detected by HPLC, the purity is 98.3%.

Embodiment 2

[0018] Take 10Kg of Tremella auricularia powder, add 90% ethanol 10 times the volume of its weight, heat and reflux 3 times, 3 hours each time, combine the reflux liquid, filter, recover ethanol under reduced pressure and concentrate, add an equal volume of acetone to extract 7 times, and combine For the acetone layer, recover the solvent and concentrate, add an equal volume of water and stir evenly, let stand overnight, filter, take the filter residue, add acetone-ethanol (1:1) to crystallize, separate the crystals, wash, and dry to obtain 289.4 g of strialic acid. HPLC detection, the purity is 98.0%.

Embodiment 3

[0020] Take 10Kg of Tremella auricularia powder, add 80% ethanol with 8 times the volume of its weight, heat and reflux twice, each time for 2 hours, combine the reflux liquid, filter, recover ethanol under reduced pressure and concentrate, add an equal volume of acetone to extract 5 times, and combine For the acetone layer, recover the solvent and concentrate, add an equal volume of water and stir evenly, let it stand overnight, filter, take the filter residue, add acetone-ethanol (1:1) to crystallize, separate the crystals, wash and dry to obtain 308.2 g of pharylic acid. As detected by HPLC, the purity is 99.6%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap