Roller type turntable bearing for super-tonnage crawler-type crane

A technology of crawler crane and slewing bearing, which is applied to cranes, roller bearings, etc., can solve the problems of increasing the production cost of bearings, increasing the processing cost, increasing the thickness of the bearing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in conjunction with embodiment and accompanying drawing:

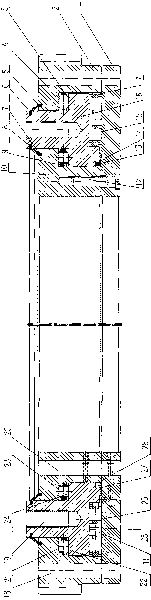

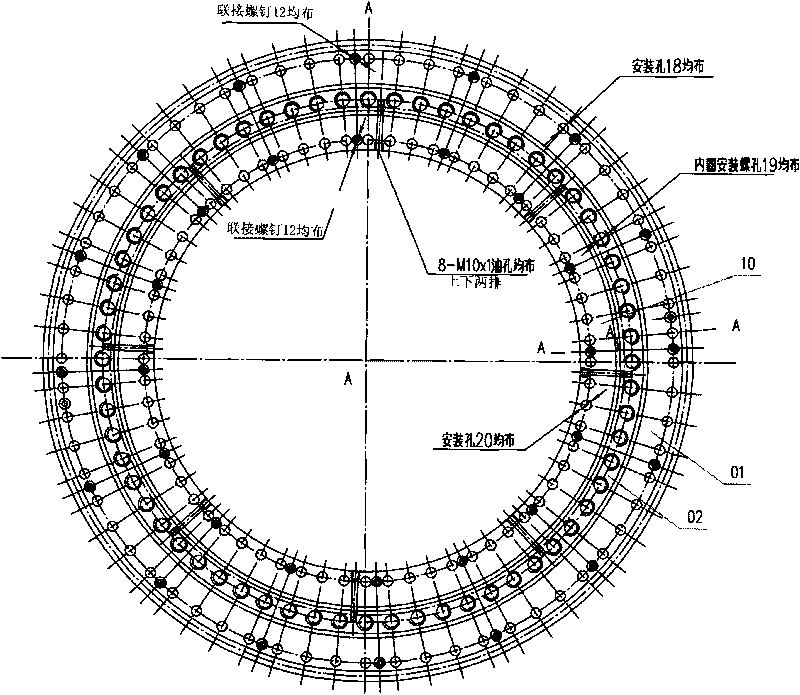

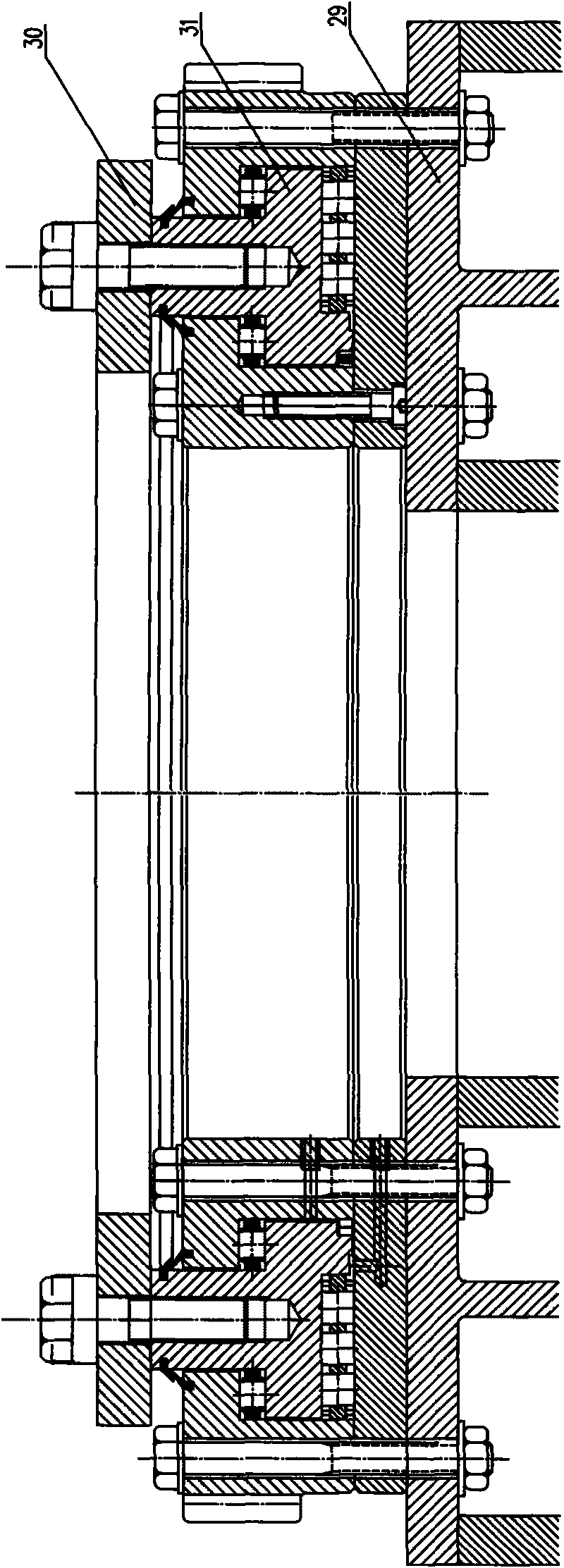

[0011] Such as figure 1 , figure 2 As shown, the slewing bearing has six rows of cylindrical rollers and five rows of cylindrical rollers are arranged in upper and lower rows, the upper two rows are auxiliary thrust rollers, and the lower three rows are main thrust rollers; the slewing bearing The axial force and overturning moment are borne by the upper and lower five rows of rollers, which greatly improves the bearing capacity of the bearing under the same outer diameter and height; the other row of radial rollers bears the load of the slewing bearing. Radial force; the six rows of rollers are located in the raceway formed by the inner ring and outer ring of the slewing bearing, and the outer ring is connected by the seat ring 1, the outer gear ring 2, and the second outer ring 10 through screws 12 constituted; that is, a row of axial rollers is set between the inner upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com