LED lamp bulb

A technology for LED bulbs and lampshades, which is applied to lampshades, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve the problems of high production cost, shortened service life of LEDs, and heavy weight, and can solve the problem of heat dissipation and prolong the The effect of long service life and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

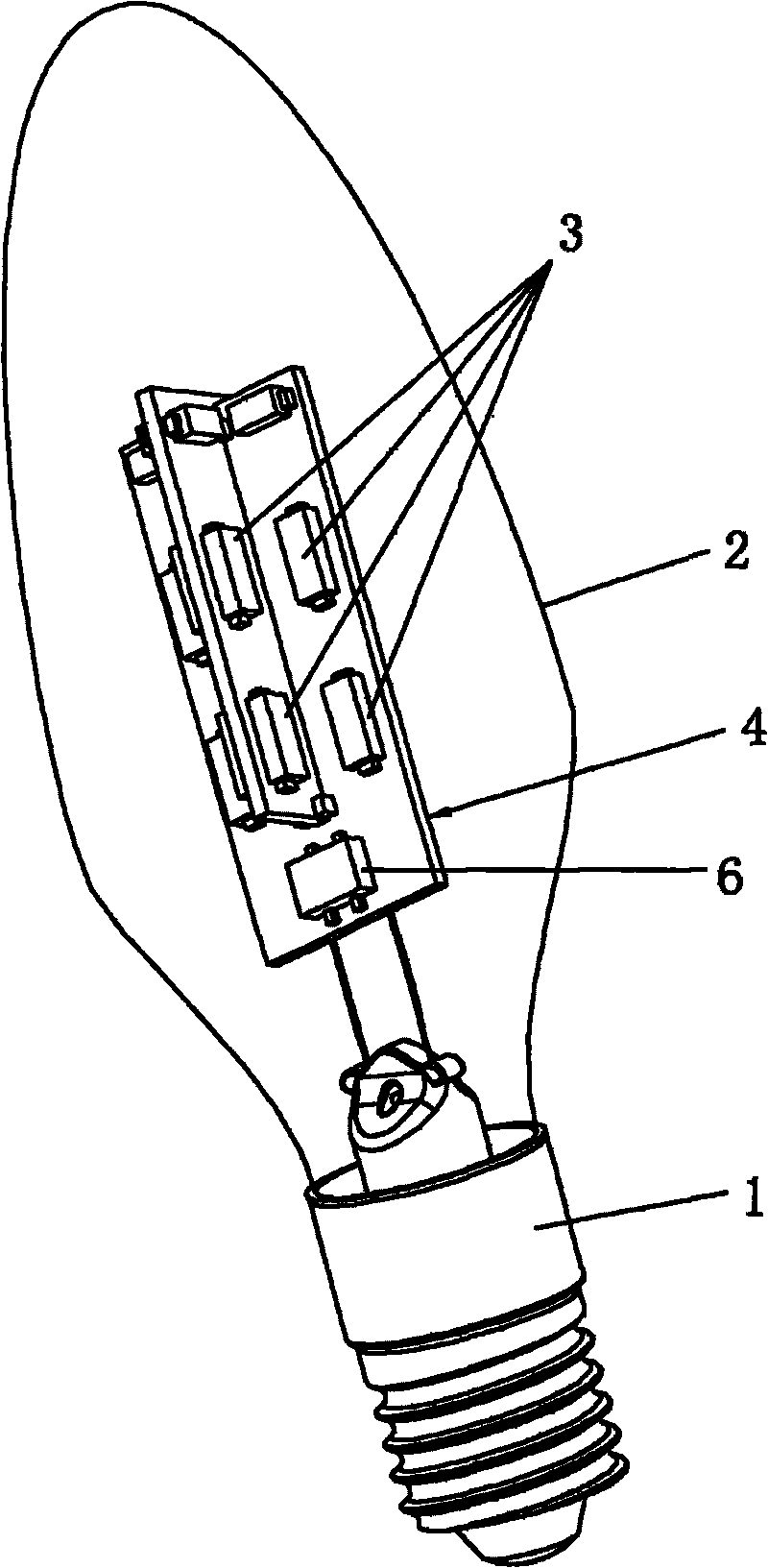

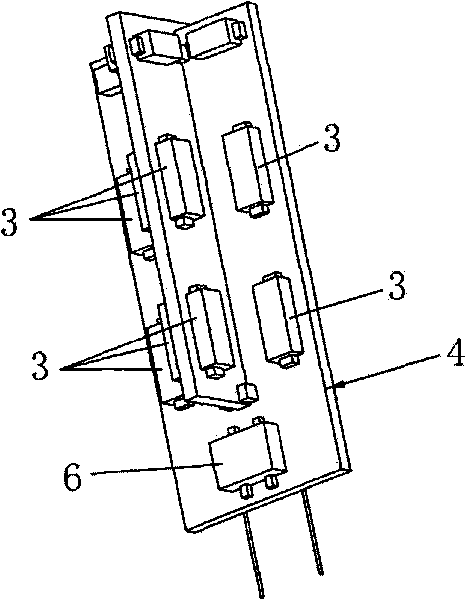

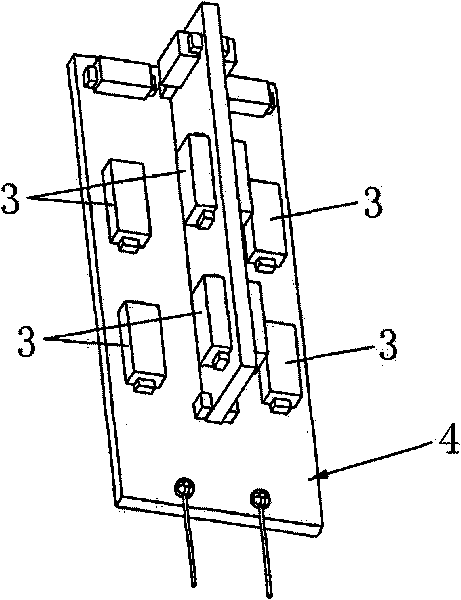

[0026] Below in conjunction with accompanying drawing, the present invention will be further described, please refer to Figures 1 to 4 The LED light bulb includes a lamp cap 1, a lampshade 2, an LED 3 and a circuit board 4. The bottom end of the lampshade 2 is installed and fixed on the top of the lamp cap 1, so that the lamp cap 1 can close the opening of the lampshade 2, and the circuit board 4 is installed and fixed on the lampshade 2. Inside, the circuit board 4 is electrically connected to the lamp holder 1 .

[0027] The lampshade 2 is filled with a mixed gas for conducting heat.

[0028] Further, the mixed gas is a mixed gas composed of nitrogen and argon, wherein nitrogen gas accounts for 30%-90% of the total volume of the mixed gas, and argon accounts for 10%-70% of the total volume of the mixed gas.

[0029] Because the lampshade of the present invention is filled with mixed gas, when the LED is working for lighting, the LED will generate heat, and the mixed gas in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com