Thermocouple lead sealing equipment

A lead wire sealing and thermocouple technology, applied in the direction of using electrical devices, measuring devices, measuring heat, etc., can solve the problems of easily damaged thermocouples and connecting wires, small sealing pressure bearing capacity of sealing surface, large shape and structure, etc., to achieve loading and unloading Convenience, good sealing performance and large pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

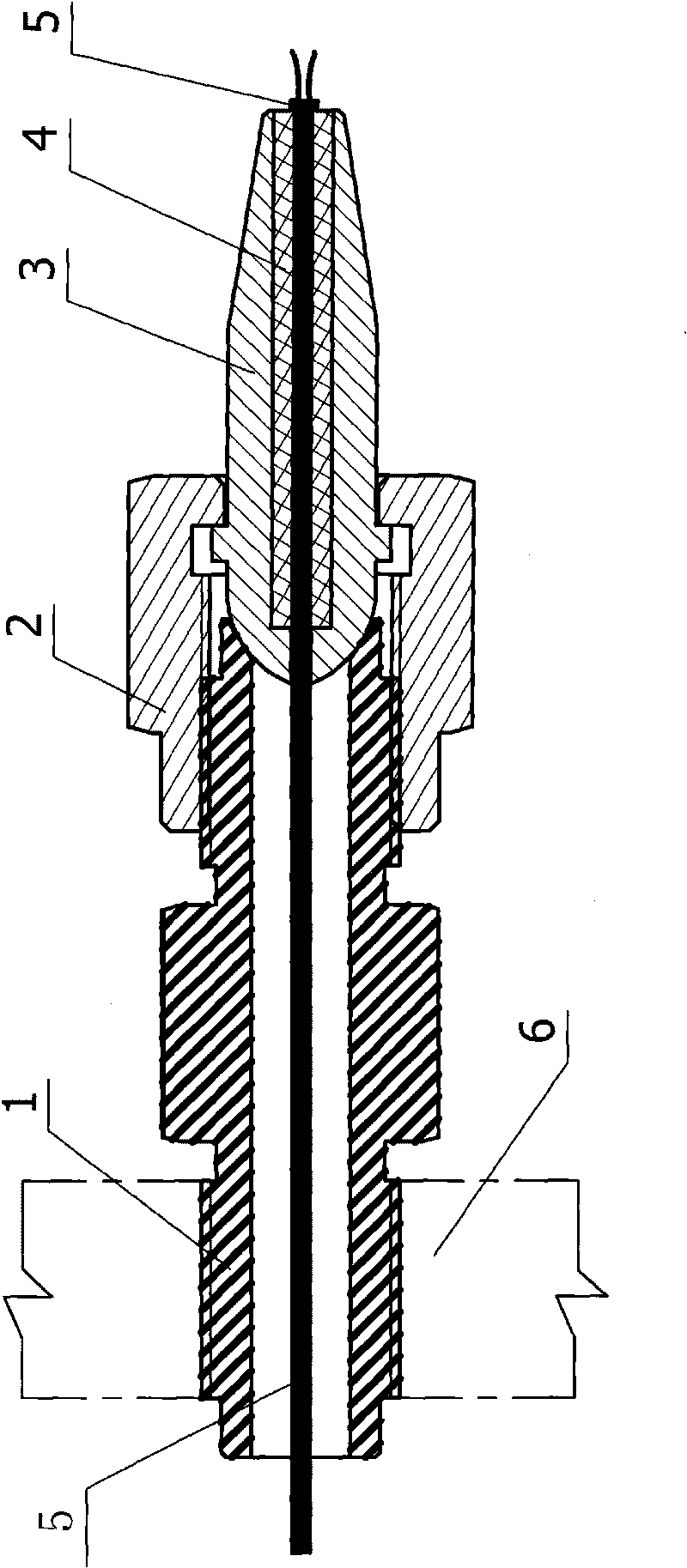

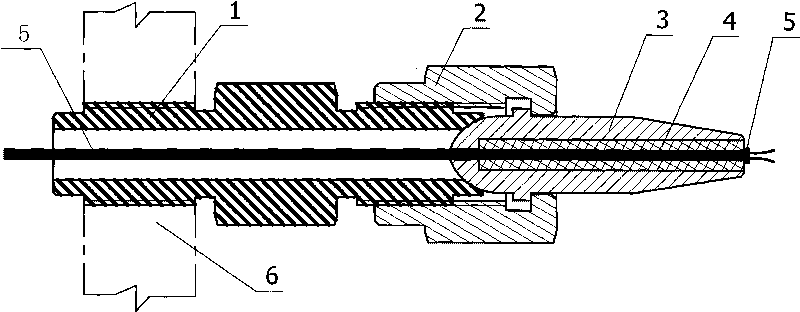

[0014] figure 1 Shown is the specific embodiment of the present invention, and it is installed in the thermocouple lead wire sealing device that measures boiler inner wall temperature with thermocouple, comprises joint, nut 2, thermocouple probe 5 and sealing surface, is characterized in that: its hollow joint 1 Both ends of the pipe are processed with external thread sections, one end of the hollow joint 1 is connected to the internal thread of the container wall, and a hemispherical sealing surface mechanism is installed in the other port of the hollow joint 1; the hemispherical sealing surface mechanism is composed of thermocouple probe 5, A nut 2, a hemispherical face head 3 and a sealant layer hole 4 are formed. One end of the hemispherical face head 3 is processed with a sealant layer hole 4, and its other end is a hemispherical face head 3, and the hemispherical face head 3 is processed with a hole for accommodating the thermocouple probe 5. Corresponding to the shape a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com