Device and method for automatically displaying vibration signal characteristics of turbo generator unit

A steam turbine generator set, vibration signal technology, applied in the direction of engine testing, measuring devices, vibration testing, etc., can solve problems such as no function, lack of in-depth analysis ability of vibration signal, inability to understand the meaning of vibration signal analysis graphics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

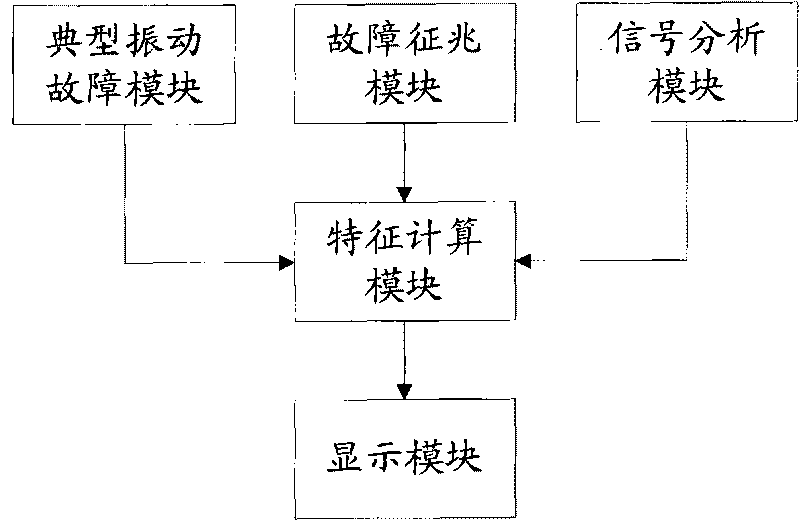

[0013] Embodiment 1: be the embodiment of device of the present invention, refer to figure 1 As shown, it includes: a characteristic calculation module, and a typical vibration fault module connected with the characteristic calculation module, a fault symptom module, a signal analysis module and a display module.

[0014] Among them, the typical vibration fault module is used to classify typical vibration faults common to turbogenerators, including rotor mass imbalance, initial bending, thermal imbalance, misalignment, rotor friction, oil film oscillation, steam flow Common faults of turbogenerator sets such as excitation, falling off and loosening of components.

[0015] The fault symptom module is used to summarize all possible symptoms of typical vibration faults, and helps to judge various phenomena of faults, including some normal phenomena, because some faults can be eliminated by using normal phenomena, mainly time domain, frequency domain and trend analysis data.

[...

Embodiment 2

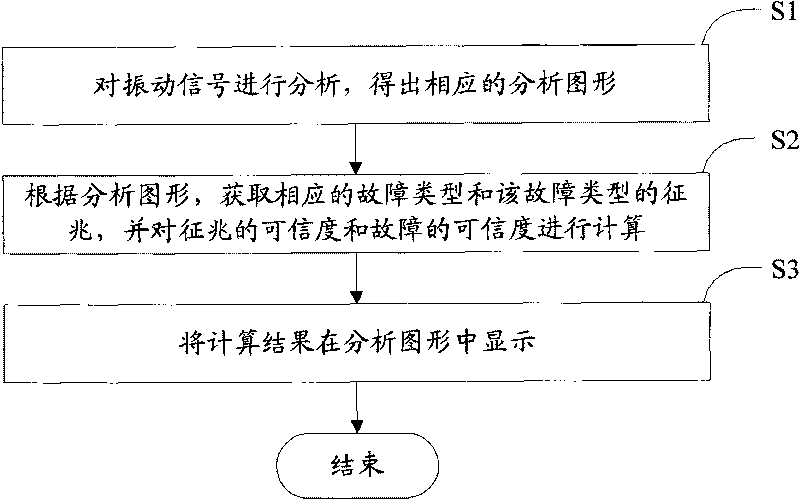

[0019] Embodiment 2: be the embodiment of the inventive method, refer to figure 2 shown, including the following main steps:

[0020] S1. Analyzing the vibration signal to obtain a corresponding analysis graph.

[0021] S2. Obtain the corresponding fault type and the symptom of the fault type according to the analysis graph, and calculate the reliability of the symptom and the reliability of the fault.

[0022] S3. Display the calculation result in the analysis graph.

[0023] More specifically, taking an unbalanced fault as an example, further details are as follows:

[0024] In the Typical Vibration Faults module, select Unbalance Faults. According to statistics, unbalance is the most common fault among the vibration faults of turbogenerator sets, accounting for more than 60%, especially during the start-up process after the new unit is put into operation and the unit is overhauled.

[0025] In the Signal Analysis module, select the Spectrum Analysis method. For variou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com